NO. 369, Road S209, Huanxiu, Qingdao City, China

NEWS

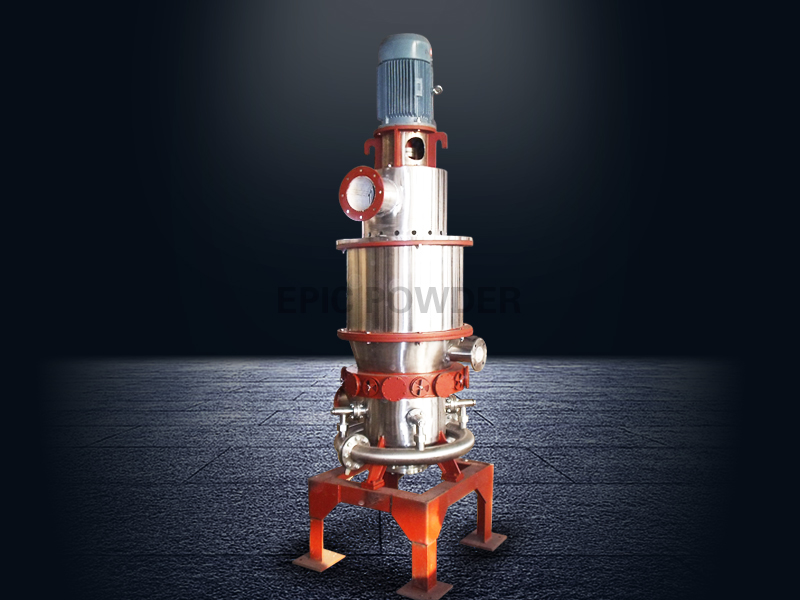

What are the advantages of jet pulverizer compared with other pulverizers?

jet pulverizer has obvious advantages over other pulverizers in its high-efficiency crushing capacity and automatic control capabilities.

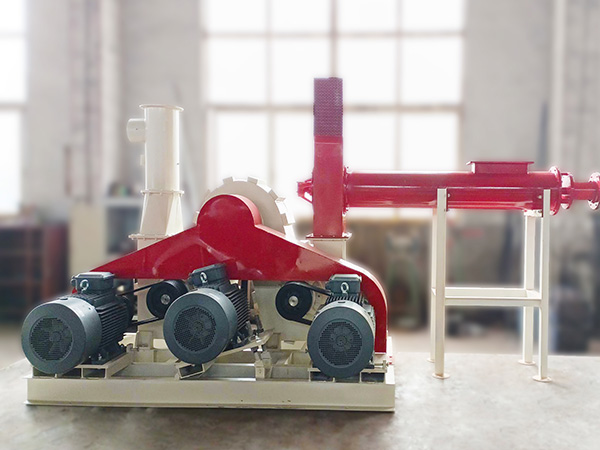

How Does Pin Mill Work: Understanding the Mechanics of Pin Milling

Pin mill is a type of grinding mill used in various industries for reducing particle size through high-speed impact.

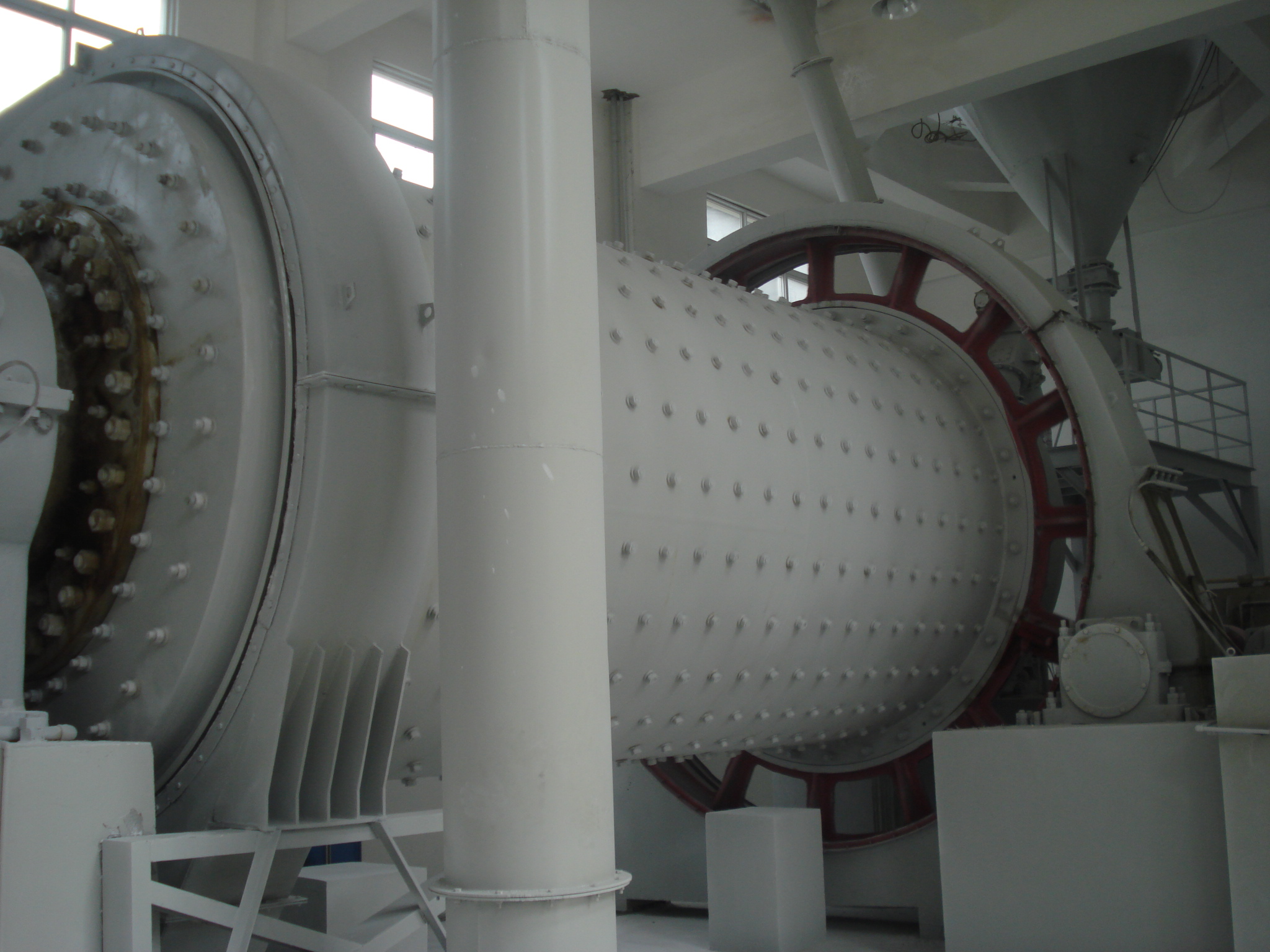

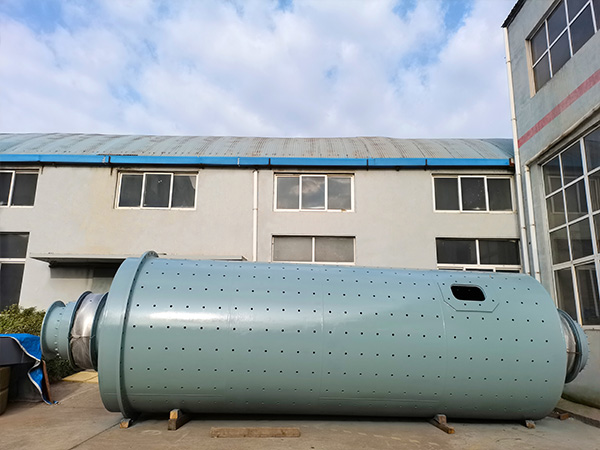

What is a non-metallic ore ultrafine ball mill classification production line?

A ball mill classification production line refers to equipment used for ultrafine grinding and classification of non-metallic minerals.

Popular science: How much do you know about bentonite?

Bentonite is an essential non-metallic mineral widely used in various fields due to its good physical and chemical properties. This article will focus on bentonite's market applications and market analysis to help readers better understand this industry.

See you Oct. 30- Nov.2 in Moscow "Khimia 2023" international exhibition

The International Exhibition “Khimia” has been held since 1965 in Moscow and it has become one of the most prestigious industrial exhibitions in the world.

Application and characteristics of calcium carbonate in PVC

Calcium carbonate is one of the most widely used fillers in plastics. It is cheap, widely available, and has a low relative density. In addition to its incremental effect on plastics, it also improves processing performance and product performance.

The application status of coal based kaolin in various industrial fields

Coal based kaolin is widely used in various industrial fields due to its simple mineral composition, pure chemical composition, high temperature resistance, good dispersibility, stable chemical properties, and excellent electrical insulation properties. The development and application of coal based hard kaolin are mainly introduced in the following industrial fields:

Achieving Unparalleled Precision in Carbon Black Grinding with the Ultrafine Pulverizer-Air Classifier Mill

The carbon black industry plays a crucial role in numerous applications, ranging from rubber manufacturing to ink production.

Advantages and Disadvantages of Impact Mills

Impact mills are machines that are used to reduce the size of particles by impacting them with a rapidly moving object. These mills are widely used in various industries, including agriculture, mining, and pharmaceuticals. In this article, we will discuss the advantages and disadvantages of impact mills.

Jet Milling: A Versatile and Efficient Method for Fine Grinding and Milling

Jet milling is a highly effective method for fine grinding and milling a wide range of materials, from pharmaceuticals and food products to industrial chemicals and minerals. This process involves using high-pressure air or steam to create a high-velocity stream of particles that collide with each other and with the material being processed, resulting in finely ground particles with a narrow particle size distribution.

What are the advantages and disadvantages of jet mills?

Jet mills are a type of equipment used in the pharmaceutical, chemical, and food industries for particle size reduction. They work by using high-pressure gas or air to create a powerful vortex that grinds particles into smaller sizes. Like any technology, jet mills have advantages and disadvantages that must be considered before deciding if they are the right option for a particular application.

Calcium Carbonate Ball Mill Classification Production Line: A Revolutionary Technology for Precise Grinding

Calcium carbonate is a common mineral that can be found in rocks, shells of marine organisms, and even in the human body. It has many uses across various industries, such as pharmaceuticals, food, and construction. However, producing high-quality calcium carbonate products can be challenging due to its complex physical and chemical properties.

What are the types of calcium carbonate grinding equipment?

Calcium carbonate grinding and pulverizing equipment are used to process calcium carbonate into a fine powder, which can be used in various applications such as construction, agriculture, papermaking, plastics, and chemicals.

Jet Mill: The Ultimate Grinding Solution

Jet milling is an advanced grinding technology that utilizes high-pressure gas jets to reduce particle size. It is a highly efficient and reliable process that is widely used in various industries, such as pharmaceuticals, chemicals, food, and cosmetics.

Application of stirring mill in grinding of non-metallic minerals such as mica, kaolin and graphite

Both the agitating mill and the traditional horizontal ball mill have a grinding cylinder, but unlike the traditional horizontal ball mill, the grinding cylinder of the agitating mill is static, and the rotation of the agitator drives the interaction between the grinding medium and minerals in the grinding cylinder to produce impact, shear, and friction, so that the feed ore particles are ground, and also has the effect of ore particle dispersion and mixing.

What are the advantages of producing quartz powder by ball mill?

What are the advantages of producing quartz powder by ball mill?Advantages of producing quartz powder using a ball mill include:

Fluidized bed jet mill is easy to operate and has high applicability

With the development of science and technology, people have higher and higher requirements for the practicality of a kind of mechanical equipment, including the

What are the functions of the nitrogen protection airflow pulverizer more than the traditional equipment EPIC Powder Machinery

The nitrogen protected air flow pulverizer is suitable for the pulverization of explosive and oxidizable substances. The nitrogen protected air flow pulverizer

EPIC Powder Machinery Application in Ore and Chemical Products

The air flow pulverizer is completely closed in the crushing process, and has a professional dust collection device, which will not cause dust leakage. This is

These three improvements have greatly improved the air flow pulverizer EPIC Powder Machinery

The domestic air jet mill enterprises have faced many problems, such as the small scale of the enterprises and the low grade. However, in recent years, the air

The manufacturer gives you a detailed introduction to the principle of the laboratory airflow grinder EPIC Powder Machinery

Laboratory air flow mill is also a small air flow mill, which is commonly used in university laboratories, enterprise laboratories, research institutions, etc.

How to deal with these common problems of jet mill? EPIC Powder Machinery

Since the introduction of the air flow mill, the working efficiency of all walks of life has also been constantly improved, and it plays an important role in th

Qingdao Juzi air flow mill can provide free incoming material test and inspection EPIC Powder Machinery

The air flow pulverizer is at the end of the process, which has a great impact on the performance of the Zui end product. Therefore, the processing of electrode

The manufacturer told you that the air flow crusher is worn fast, so EPIC Powder Machinery can do this

Many manufacturers who want to carry out crushing process will choose to purchase an air flow mill, but not all air flow mills can be used for production and pr

The good preparation effect of air jet mill for battery materials is due to these EPIC Powder Machines

Battery material air flow pulverizer is an indispensable part of battery material processing. Its role is to fine process battery raw materials, so that coarse