NO. 369, Road S209, Huanxiu, Qingdao City, China

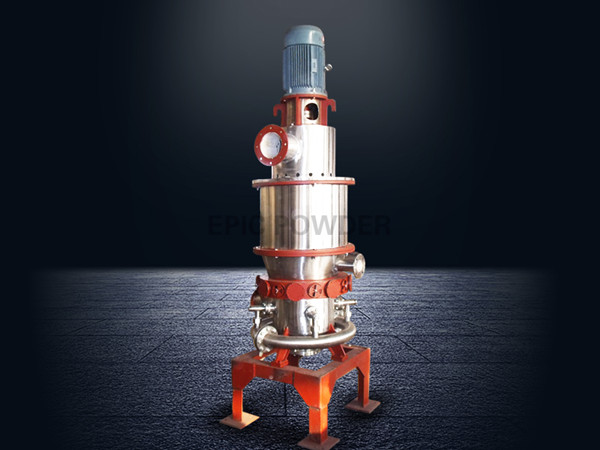

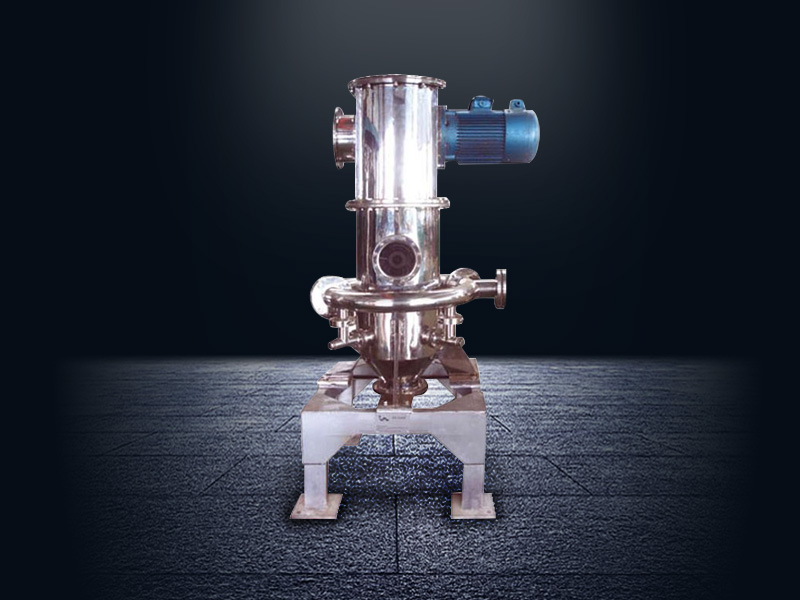

Fluidized Bed Opposed Air Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

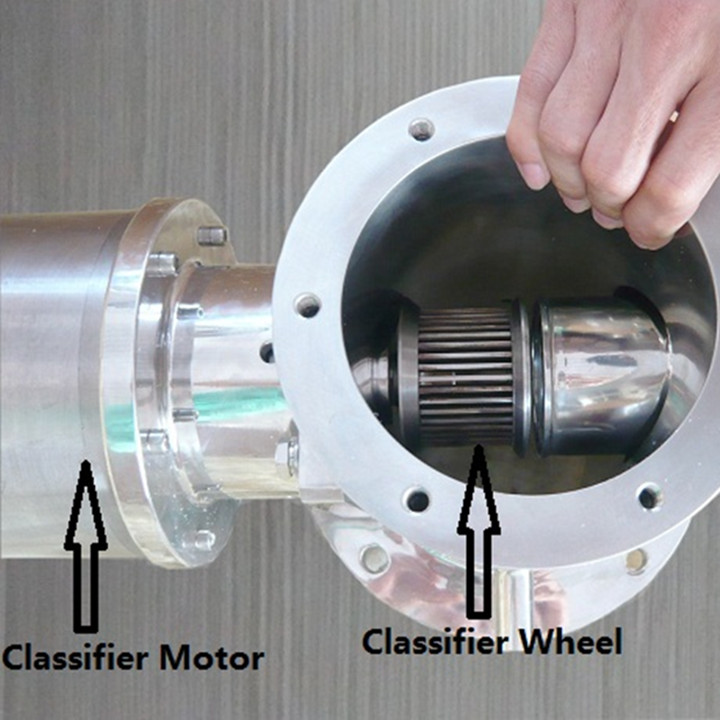

Fluidized Bed Opposed Air Jet Mill incorporates dense phase micronization using turbulent, free jets in combination with high efficiency centrifugal air classification within a common housing. This combination allows for enhanced comminution by high probability particle-on-particle impact for breakage and a high degree of particle dispersion for improved separation.

- Low-temperature pulverization without medium, especially suitable for heat-sensitive, low-melting materials.

- Control particle sizes precisely, available particle size D50:1~25μm.

- Grinding in a complete closed system, no dust, low noise, clean and environmentally friendly.

- Jet Milling is an effficient way to mill or micronize various chemicals, polymers, ceramics and other friable materials. Abrasive and temperature-sensitive products can be finely ground with minimum contamination. The simple, easy-to-clean, cost-effective design offers precise top size control with narrow size distributions in the 95% < 5 um to 95% < 70 um size range. Load cells are used to precisely control mill load for optimum grinding efficiency and/or product size distribution control.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.