NO. 369, Road S209, Huanxiu, Qingdao City, China

NEWS

The market demand for modified plastics is strong, and the industry concentration will further incre

Modified plastics refer to plastic products that are processed and modified by filling, blending, strengthening, and other methods based on general plastics and engineering plastics to improve the properties of flame retardancy, strength, impact resistanc

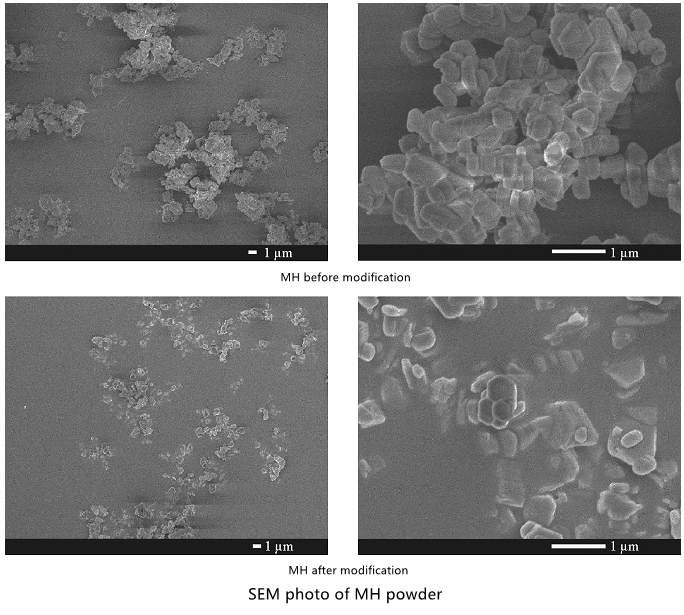

Effects of Aluminate Coupling Agent Modification on Dispersibility and Compatibility of Magnesium Hy

In recent years, halogen-free flame retardants such as magnesium hydroxide (MH), aluminum hydroxide (AH), and aluminum magnesium hydroxide (MAH) have been widely studied due to their green and pollution-free advantages, and their use has also become a tre

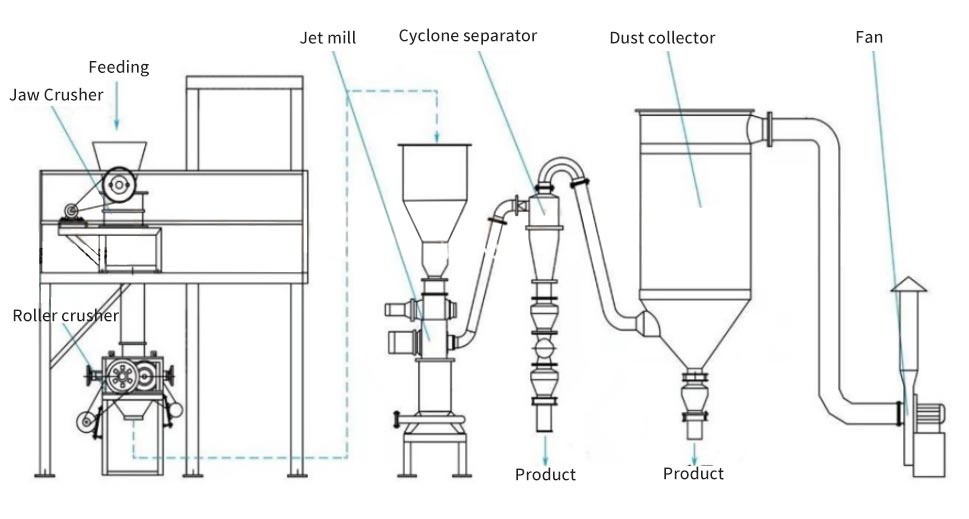

Principle and characteristics of spiral jet mill

The working principle of the spiral jet mill and The equipment characteristics of the spiral jet mill.

Spiral jet mill and working principle of jet mill

EPIC Powder introduces the working principle and application of the spiral jet mill (also known as the flat type or disc type) in the jet mill.

The fineness and purity of the Fluidized Bed Opposed Air Jet Mill are the main performance “highligh

The Fluidized Bed Opposed Air Jet Mill has various properties such as winnowing type, no screen, no net, uniform particle size, etc.

Advantages of ultra-fine Fluidized Bed Opposed Air Jet Mill

Ultra-fine Fluidized Bed Opposed Air Jet Mill is a kind of equipment for producing ultra-fine powder. It is the equipment with smaller fineness on the market at present. It is suitable for building materials, chemicals, fillers, plastics, papermaking, coa

The composition & function of the air classifier system

The Air Classifier is mainly composed of a feeding control system, a classifier host (1-4 units), a high-efficiency cyclone collector, a pulse bag filter, a high-pressure induced draft fan and an electrical control system.

Installation precautions of air classifier

What precautions should be taken when installing an air classifier? Let the engineers at EPIC Powder Machinery tell you.

Ternary material grinding process and equipment

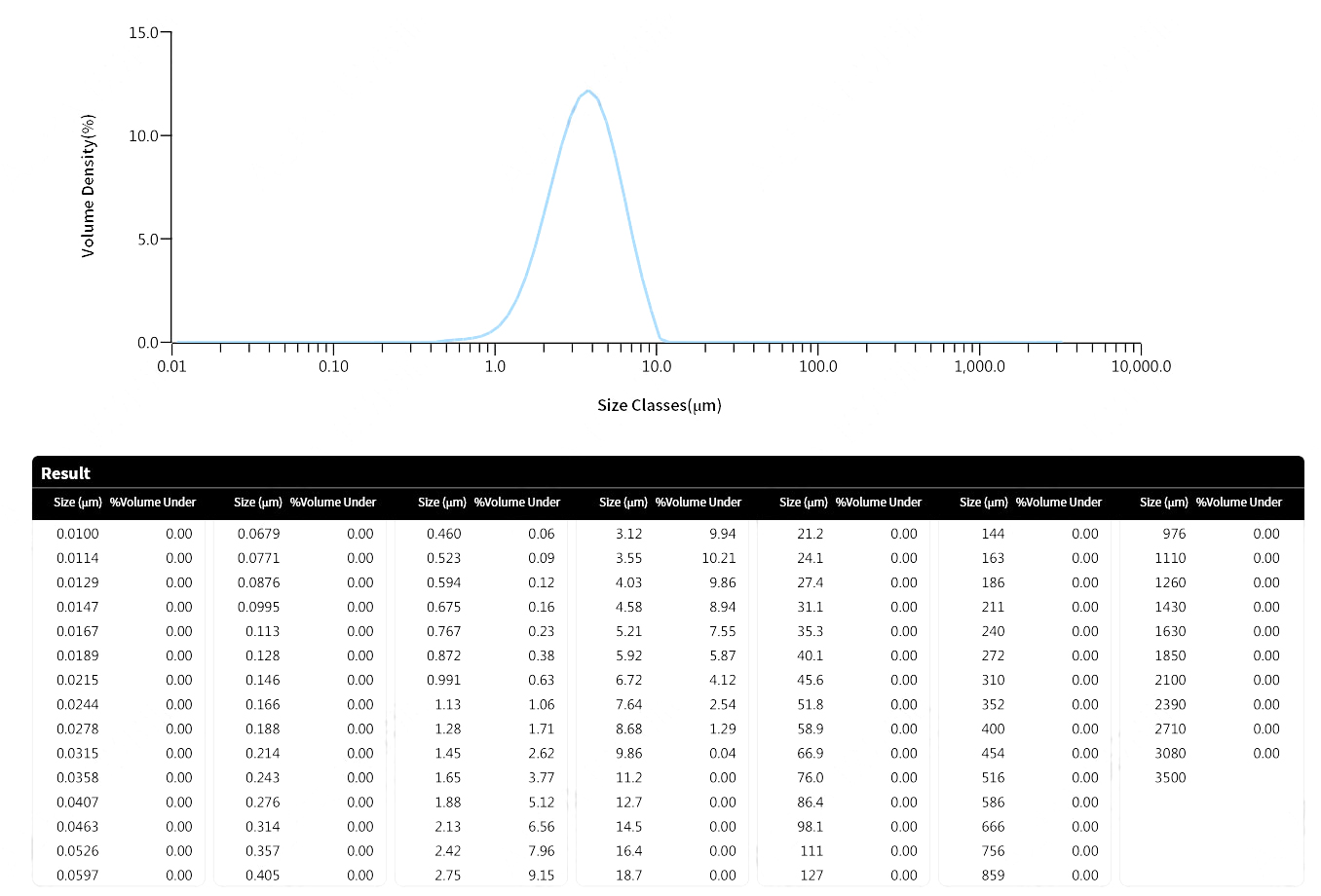

The ternary material is a secondary sphere formed by agglomeration of single crystals of about 1μm, and the particle size of the secondary sphere is 3-40μm.

Ultra-fine grinding of non-metallic minerals

Non-metallic mines, metal mines, and fuel mines are called the three pillars of the materials industry. The use of non-metallic minerals depends on the degree of deep processing, including ultra-fine grinding, ultra-fine grade, fine purification and surfa

Characteristics and typical models of jet mill

With the rapid development of the global economy, the powder industry is booming, and powder equipment, especially ultra-fine grinding equipment, plays a key role in it. The jet mill is one of the most common ultra-fine grinding equipment.

How Kaolin Affect Mechanical Properties of Rubber

Filling natural rubber with kaolin can better develop the resources in China and maximize the applications of natural rubber.

In order to achieve fine quartz powder, some grinding aid is normally added during grinding.

Quartz is hard and not easy to grind, so in quartz grinding, it is difficult to achieve the ideal fineness only by grinding with grinding media. In order to achieve fine quartz powder, some grinding aid is normally added during grinding.

Pickling Effect of Quartz Sand Origins

Quartz is widely distributed in China. Does the origin of quartz sand affect pickling? Experimental data of the pickling of quartz sand from different origins has been collected after repeated experiments, which is instructive for the pickling process.

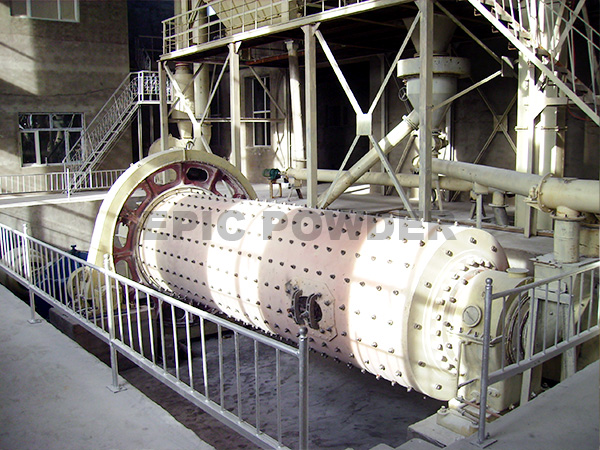

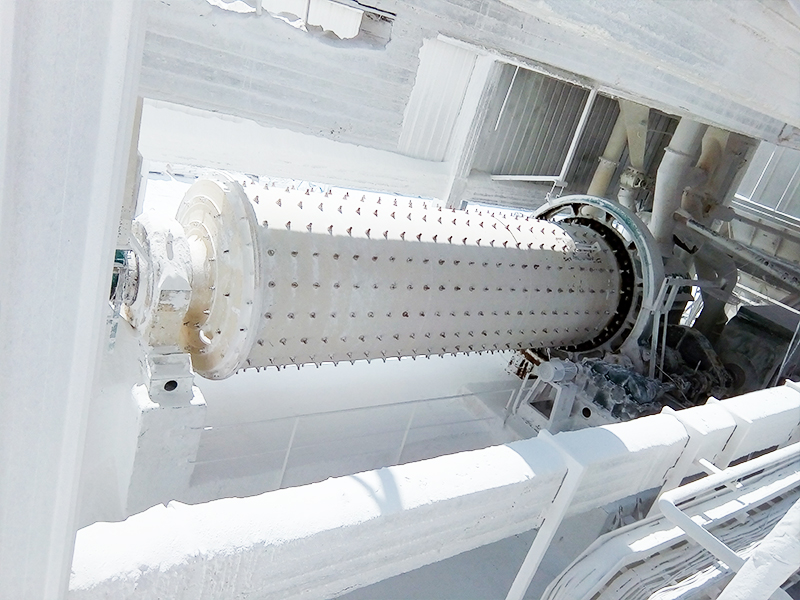

The steps & principles of purchasing a ball mill

As we all know, ball mill equipment is a professional equipment for grinding materials. From the beginning of grinding metallurgy and mining industry, it has flourished in many industries.

Application of jet mill in biopharmaceutical

Jet mills are mainly used in industry, agriculture, chemical industry, metallurgy, etc., such as cement, minerals, fertilizer production, etc. With the improvement of technology and the development of biopharmaceutical technology, jet mills are gradually

Seven Promising Applications of Shell Powder

Shell is an important biomineralization material, composed of 95% of calcium carbonate and 5% of organic matter. Its unique structure and components can be greatly applied to environmental pollution control, polymer materials, coatings, pigments, health c

The application of talc powder in plastics

As an additive, modifier, or filler, talc powder has been widely used in papermaking, paint, coatings, ceramics, chemicals for daily use, plastics, food, medicine, and other industries. Talc has the properties of soft texture, easy-grinding, high gloss,

Happy New Year

Qingdao EPIC Powder Machinery Co., Ltd. wishes all customers a happy new year and all the best in 2022.

The Role of Carbohydrate in the Crystallization of Calcium Carbonate Nano Particles

At present, metal salts, organic acids, inorganic acids, polyvinyl alcohol, amino acids, surfactants are often used as crystal control agent of calcium carbonate nanometer particles.

Precautions & maintenance steps before assembling the grinder

Privacy PolicyThis Application collects some Personal Data from its Users.Types of Data collectedAmong the types of Personal Data that this Application collects

[Powder in life] Talc is everywhere

Talc gets its name because of its soft texture and strong creaminess. It is a water-containing magnesia silicate mineral with a layered structure, mainly containing magnesium silicate, alumina, nickel oxide and so on.

Production and modification process of heavy calcium carbonate

Heavy calcium carbonate, also known as ground calcium carbonate, or heavy calcium for short, is made by processing natural carbonate minerals as raw materials.

Types of grinding media balls

When the ball mill is working, it relies on the impact and grinding action of the medium on the material to complete the grinding of the material.

![[Powder in life] Talc is everywhere](/d/file/20211025/5f44fce6a8b308b29756fe16564c2363.jpg)