NO. 369, Road S209, Huanxiu, Qingdao City, China

calcium carbonate

Application and characteristics of calcium carbonate in PVC

Calcium carbonate is one of the most widely used fillers in plastics. It is cheap, widely available, and has a low relative density. In addition to its incremental effect on plastics, it also improves processing performance and product performance. This material has a softer texture and causes less wear on kneaders and forming machines. At the same dosage, the surface scratching and bending whitening properties of products filled with light calcium carbonate are smaller than those filled with heavy calcium carbonate. The biggest feature of light calcium carbonate is its reinforcing effect, which can improve the impact strength of products. Heavy calcium carbonate used in plastics can reduce costs, has good affinity with resins, has high dispersion, has a refractive index similar to that of plastics, is easy to color, and can improve the strength and stability of plastic products. The most mature industry for applying nano calcium carbonate is the plastics industry, which is mainly used in high-end plastic products.

Calcium carbonate is a non-toxic substance. The US FDA recognizes this product as a "safety substance" and can be used in plastic products that come into contact with food. Calcium carbonate is compounded with polyolefin resins such as polyvinyl chloride, polyethylene, and polypropylene to produce calcium plastic materials.

Polyvinyl chloride (PVC)

Calcium carbonate-filled PVC is made by kneading PVC, calcium carbonate (such as heavy calcium carbonate, light calcium carbonate, micronized calcium carbonate, precipitated calcium carbonate, activated calcium carbonate, etc.), and other additives according to the ingredients ratio. , mixed, and then granulated, extruded, or injection molded into the required products; it can also be rolled and pressed into sheets or plates, which are flame-retardant, resistant to acids, alkalis, and chemicals, water-resistant, moisture-proof, sound insulation, and coloring It has the characteristics of good durability. Also, it has the advantage of being cheaper than ordinary PVC plastic.

Calcium carbonate is used to fill polyvinyl chloride. It can be used in hard products such as plates and pipes and in soft products such as wire coverings and artificial leather. It can improve the color stability of the products. Used in polyvinyl chloride paste as a viscosity regulator. This product has a high oil absorption value, absorbs a large amount of plasticizer, and has poor dispersion uniformity in soft polyvinyl chloride. When the mixing amount is large, the surface smoothness of extruded products will be reduced. Used together with white carbon black, it can improve dispersion uniformity. Calcium carbonate-filled PVC hard products can replace steel and wood in construction projects, transportation, and furniture production, such as making door and window profiles, ceilings, partition boards, corrugated boards, floors, car and boat cabin boards, and wire ducts. Boards, furniture, board-frame or corrugated packaging boxes, building drainage pipes, industrial sewage pipes, etc. At the same time, it can also make soft products such as films, artificial leather, sheets, wire sheaths, and opaque hoses.

Using 5 to 10 parts of ultra-fine calcium carbonate in rigid polyvinyl chloride can significantly improve the impact strength. Ultra-fine calcium carbonate surface-treated with coupling agents, etc., can improve the processing and formability of products and have better-reinforcing effects. It can be used as a cheap substitute for the anti-impact agent, and the dosage in rigid polyvinyl chloride can reach 20 to 30 parts. Ultrafine calcium carbonate is used in polyvinyl chloride. The surface of the product is smooth and clean. It can cause astigmatism and matte light. It can improve the dimensional stability and tensile strength of plastic products. It can increase the transparency of transparent and translucent materials and improve the quality of the product. Surface gloss and surface smoothness. Ultrafine calcium carbonate can also increase the insulation, flame retardancy, and electroplating properties of PVC products.

Light calcium carbonate is one of the most widely used inorganic fillers. It has a thermal stabilizing effect in some soft polyvinyl chloride. Its use can reduce the amount of heat stabilizers or allow cheaper stabilizers such as barium. Zinc and calcium-zinc replace higher-priced heat stabilizers such as barium-cadmium or barium-cadmium zinc. Adding light calcium carbonate or surface-treated light calcium carbonate to rigid polyvinyl chloride can improve the dimensional stability of plastic products, increase the product's hardness, improve the processing and formability of the plastic, and improve the heat resistance of the plastic product.

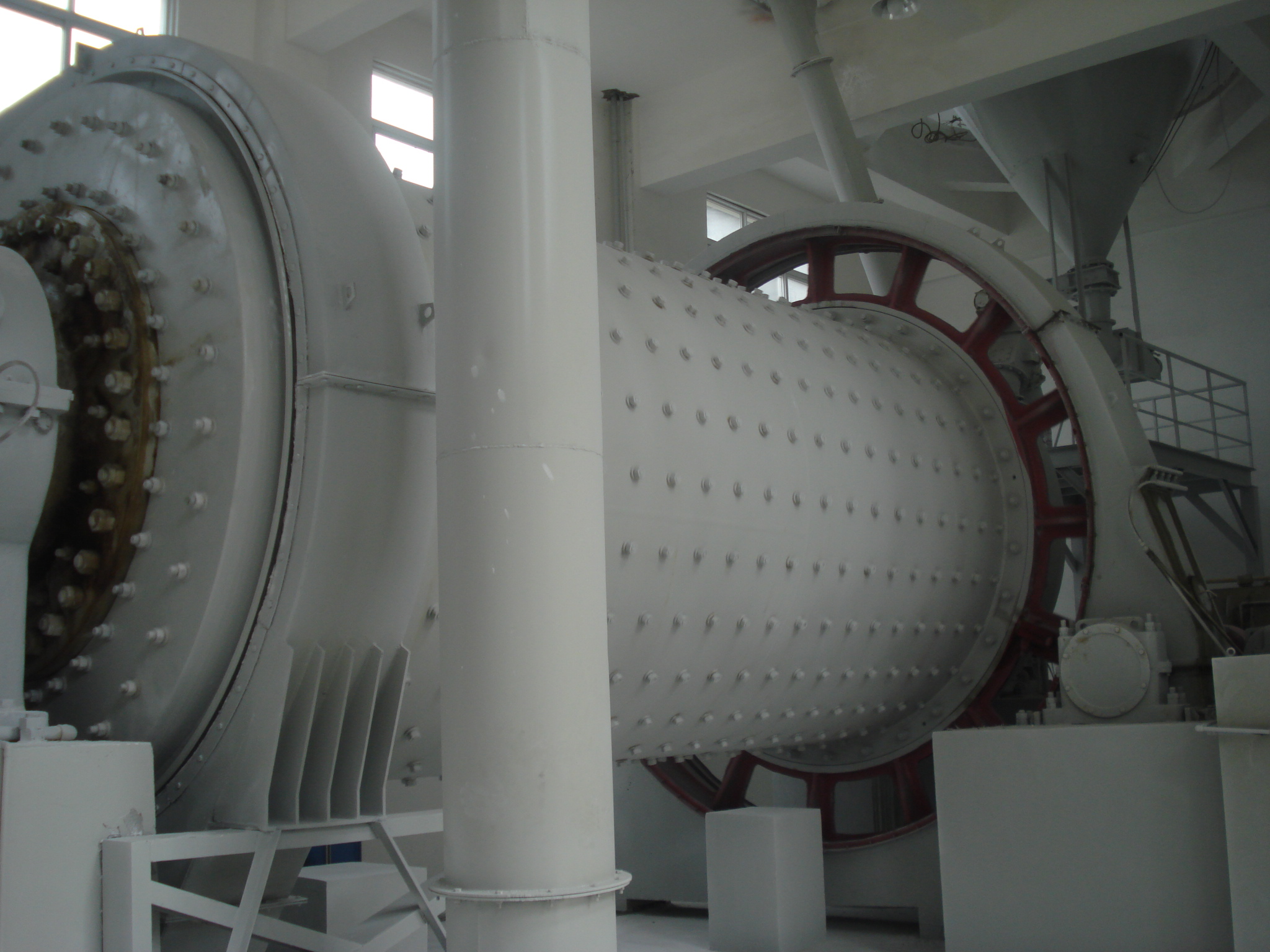

Applying heavy calcium carbonate in polyvinyl chloride focuses on increasing the filling amount to reduce the production cost of the product. With the advancement of mechanical grinding technology, heavy calcium carbonate has gradually replaced light calcium carbonate in PVC composite materials. In industrially developed countries, the dosage ratio of heavy calcium carbonate to light calcium carbonate is 20:1. It is a trend for heavy calcium carbonate to replace light calcium carbonate in some applications.

In addition to reducing costs, using heavily activated calcium carbonate as a filler in polyvinyl chloride resin can improve the processing performance of products and reduce mold wear. Lightweight activated calcium carbonate is used in PVC cable materials to improve electrical insulation properties.

By measuring impact strength, tensile strength, elongation at break, and material rheological properties, the effects of nanoscale calcium carbonate and micron-scale calcium carbonate on the mechanical properties and processing properties of flame-retardant soft polyvinyl chloride were comparatively studied. The conclusion is that the composite flame retardant system of hydroxide and metal complexes will deteriorate the mechanical properties of the material while improving the flame retardant and smoke elimination properties of soft polyvinyl chloride; nanometer calcium carbonate can significantly improve the flame retardant soft polyvinyl chloride. The impact strength, tensile strength, and elongation at the break of vinyl chloride have obvious toughening and reinforcing effects on the material.

Leave a Comment