NO. 369, Road S209, Huanxiu, Qingdao City, China

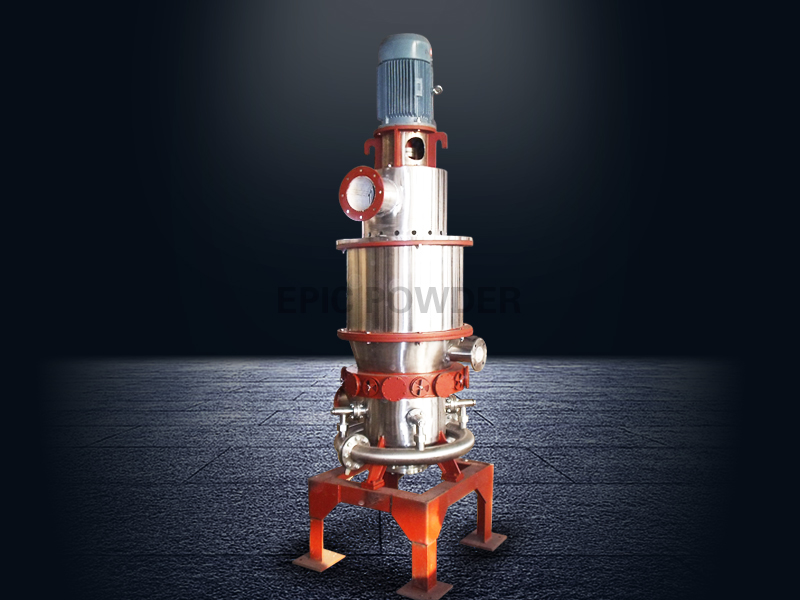

Jet mill

Jet Milling: A Versatile and Efficient Method for Fine Grinding and Milling

Jet milling is a highly effective method for fine grinding and milling a wide range of materials, from pharmaceuticals and food products to industrial chemicals and minerals. This process involves using high-pressure air or steam to create a high-velocity stream of particles that collide with each other and with the material being processed, resulting in finely ground particles with a narrow particle size distribution.One of the key advantages of jet milling is its versatility. It can be used to produce particles ranging in size from just a few microns up to several millimeters, making it suitable for a wide range of applications. Additionally, jet milling is a dry process, which means that it can be used to produce fine powders without the need for additional drying or processing steps.

Another advantage of jet milling is its efficiency. Because the process is highly controlled, it can produce particles with a very narrow size distribution, which is important for many applications. Additionally, jet milling can be used to produce large quantities of material in a relatively short amount of time, making it a cost-effective option for many manufacturers.

There are several different types of jet mills available, including Fluidized Bed Jet Mills, opposed jet mills, and spiral jet mills. Each type has its own unique advantages and disadvantages, depending on the specific application.

Overall, jet milling is a versatile and efficient method for fine grinding and milling a wide range of materials. Its ability to produce finely ground particles with a narrow size distribution, combined with its cost-effectiveness and flexibility, make it an attractive option for many manufacturers.

Leave a Comment