NO. 369, Road S209, Huanxiu, Qingdao City, China

calcium carbonate grinding equipment

What are the types of calcium carbonate grinding equipment?

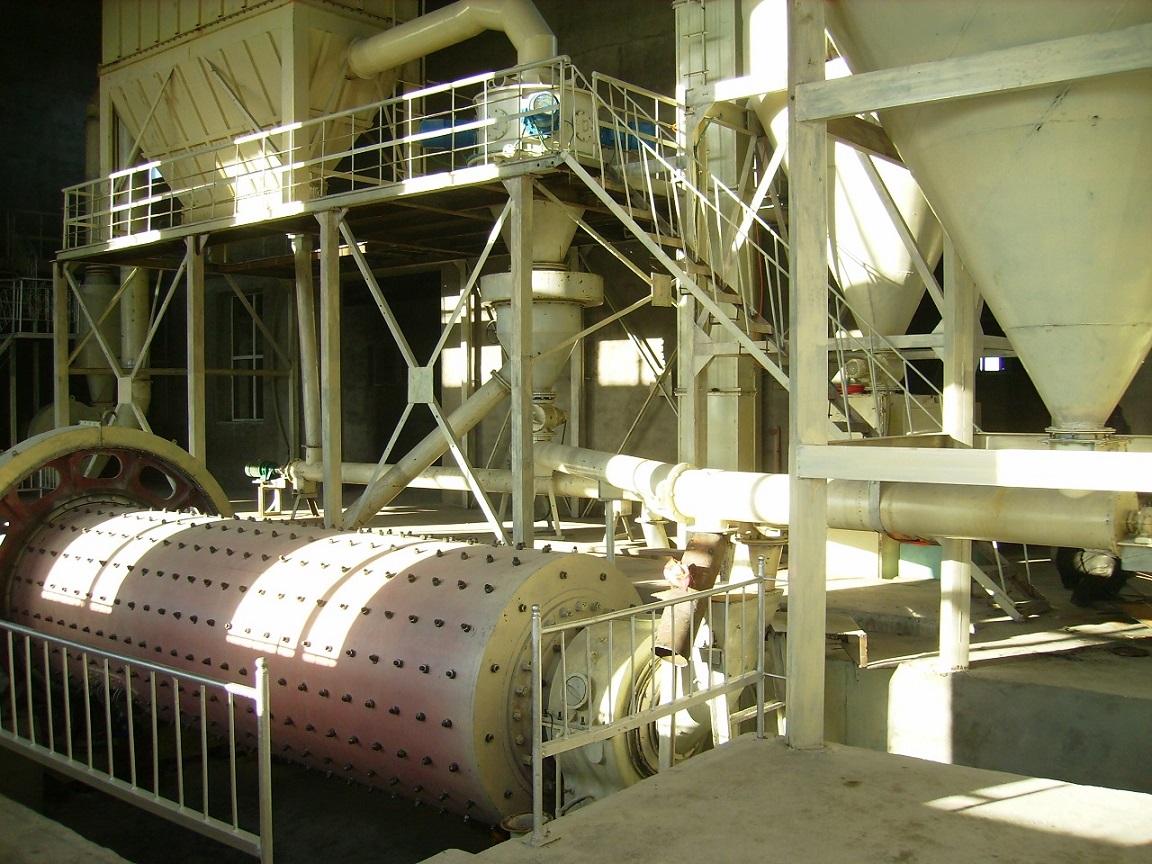

Calcium carbonate grinding and pulverizing equipment are used to process calcium carbonate into a fine powder, which can be used in various applications such as construction, agriculture, papermaking, plastics, and chemicals. There are several types of calcium carbonate grinding equipment available in the market with varying capabilities, advantages, and disadvantages. In this article, we will discuss the different types of calcium carbonate grinding equipment and their respective product particle size ranges, advantages, and disadvantages.Ball Mill

Ball mills are one of the most common types of grinding equipment used in the production of calcium carbonate powder. The ball mill consists of a rotating cylindrical shell filled with steel balls. The material to be ground is added to the cylinder along with the steel balls, and the cylinder rotates to create a cascading effect that grinds the material into fine particles. Ball mills can produce calcium carbonate particles in the range of 1-100 microns.

Ball Mill Advantages:

Suitable for large-scale production

High grinding efficiency

Can produce a wide range of product particle sizes

Ball Mill Disadvantages:

High energy consumption

Require frequent maintenance

Not suitable for processing heat-sensitive materials

Raymond Mill

Raymond mills are another commonly used type of calcium carbonate grinding equipment. They consist of a rotating bowl with rollers that press against a ring to grind the material. The material is fed into the bowl from the top and the rollers rotate around the bowl to crush and grind the material into fine particles. Raymond mills can produce calcium carbonate particles in the range of 80-400 mesh.

Raymond Mill Advantages:

Low operating costs

Simple operation and maintenance

Can produce a narrow range of product particle sizes

Raymond Mill Disadvantages:

Lower grinding efficiency compared to ball mills

May generate more dust during operation

Limited capacity

Vertical Roller Mill (VRM)

Vertical roller mills are a newer type of calcium carbonate grinding equipment that has gained popularity in recent years. They consist of a rotating table with rollers that grind the material between them. The material is fed into the mill from the top and the rollers rotate around the table to grind the material into fine particles. VRM can produce calcium carbonate particles in the range of 10-45 microns.Vertical Roller Mill Advantages:

High grinding efficiency

Low energy consumption

Can handle heat-sensitive materials

Vertical Roller MillDisadvantages:

Higher initial investment cost

Limited capacity compared to ball mills

Maintenance can be complicated

Ring Roller Mill

Ultrafine mills are a type of grinding equipment that can produce extremely fine particles of calcium carbonate. They use centrifugal force to grind the material between the rotating rotor and stationary stator. The material is fed into the mill from the top and the rotor rotates at high speed to grind the material into fine particles. Ultrafine mills can produce calcium carbonate particles in the range of 1-10 microns.

Ring Roller Mill Advantages:

Can produce extremely fine particles

Low energy consumption

High grinding efficiency

Ring Roller Mill Disadvantages:

High initial investment cost

Limited capacity compared to other types of mills

May generate more dust during operation

Conclusion

In conclusion, there are several types of calcium carbonate grinding and pulverizing equipment available in the market, each with its advantages and disadvantages. Ball mills and Raymond mills are commonly used in the production of calcium carbonate powder, while vertical roller mills and ultrafine mills are newer types of equipment that offer higher grinding efficiency and finer product particle sizes. When selecting grinding equipment, it is important to consider the capacity, product particle size range, and specific requirements of the application.

Leave a Comment