NO. 369, Road S209, Huanxiu, Qingdao City, China

NEWS

Development, Advantages and Disadvantages of Domestic Jet Mill

Jet mill is an equipment that crush materials under the action of high-speed air flow through the impact between particles, the impact and shear of air flow on materials, and the impact, friction and shear of materials and other parts. It is reported that

Application of non-metallic mineral materials as additives in lubricating oil

In recent years, the study of inorganic silicate natural minerals as new lubricant anti-friction and anti-wear additives has received extensive attention at home and abroad and has gradually become a research hotspot in the field of tribology.

【Technical Information】Causes of High-speed Airflow in Jet Mill: Laval nozzle

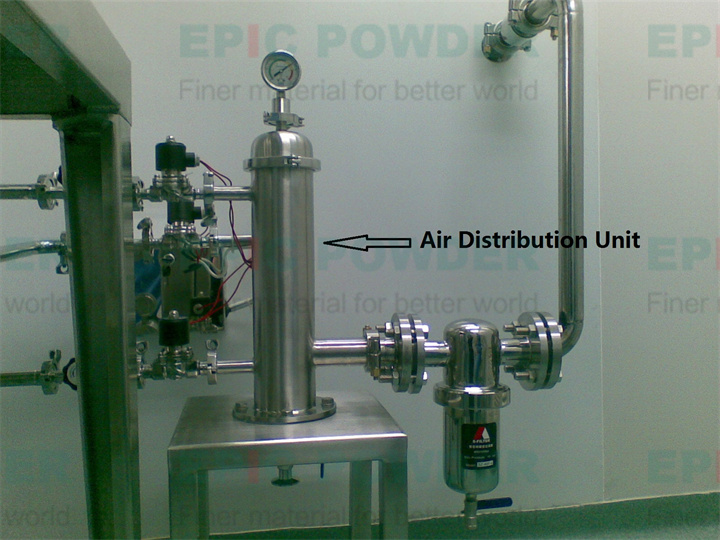

The compressed air used in the jet mill is sprayed into the crushing chamber at a high speed through the Laval nozzle after being filtered and dried. At the intersection of multiple high-pressure air streams, the materials are repeatedly collided, rubbed

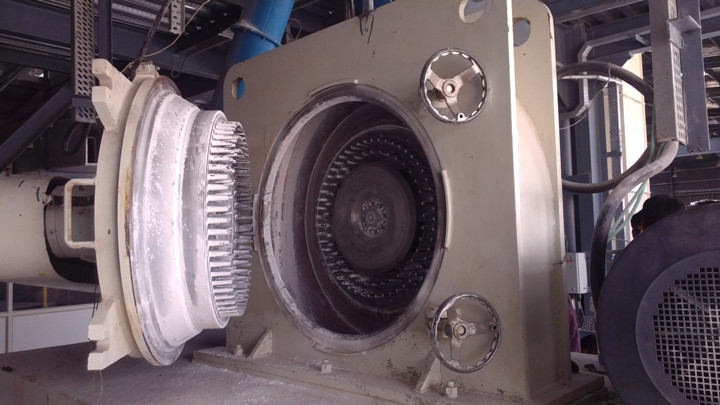

Jet Mill: Full of Practical Information! The detailed explanation of the working principle of variou

Jet mill technology is widely used in the superfine pulverization of various materials. The jet pulverized materials have the characteristics of ultra-fine and ultra-pure, smooth particle surface, regular particle size, high activity, etc. However, there

Working Principle of Jet Mill and Precautions in Operating

Jet mill is a very unfamiliar name to non-industry people. In daily life, many products are inextricably related to jet mill. Qingdao EPIC Powder Machinery Co., Ltd. will explain the working principle of the jet mill and the precautions in operating.

The calcium carbonate industry is highly competitive, focusing on the development of high-end produc

China is the world's largest producer and consumer of calcium carbonate, with annual production and sales accounting for more than 30% of the world's total. In 2020, the market size will reach 7 billion yuan. The production areas are mainly concentrated

What are the commonly used surface modification agents for calcium carbonate? how to use?

Calcium carbonate is currently the most used inorganic filler in polymer-based composite materials. However, since the calcium carbonate filler is an inorganic powder and has poor compatibility with organic polymers, it is difficult to evenly disperse whe

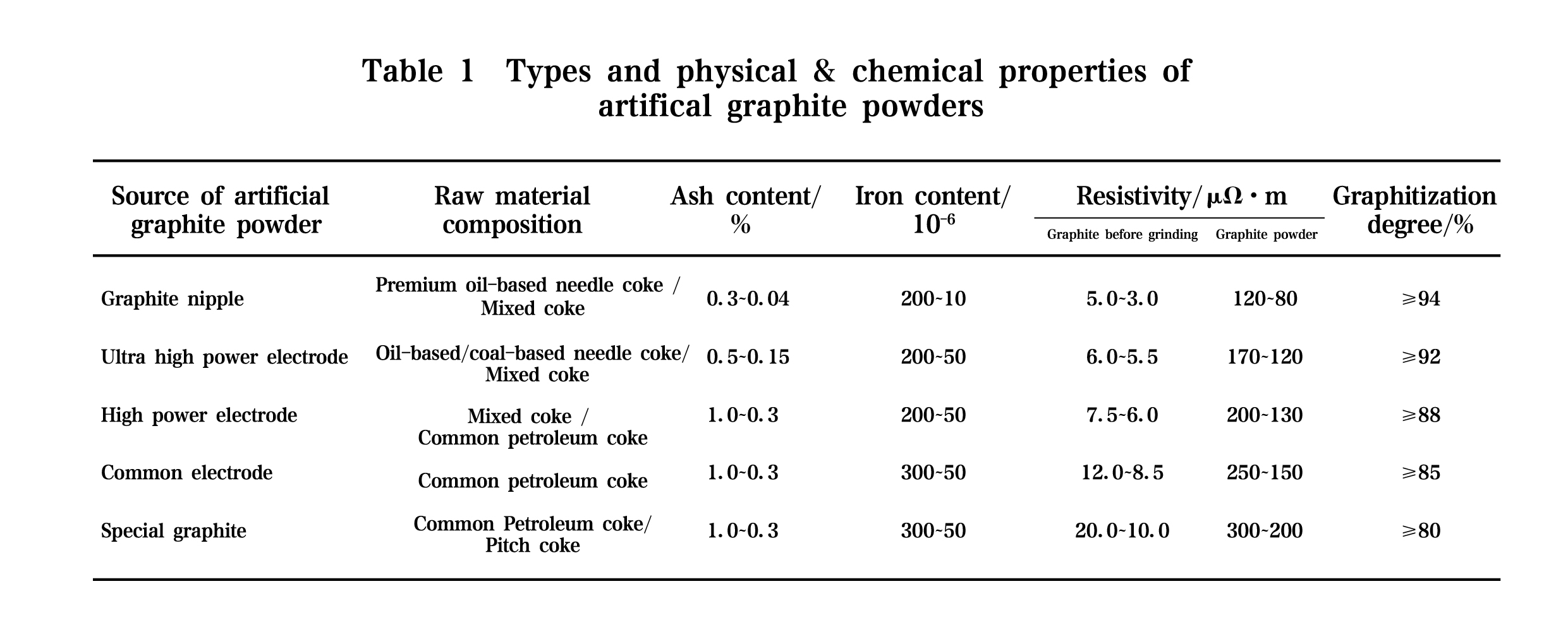

An article to understand artificial graphite powder and its application in lithium battery anode mat

Artificial graphite products produce a certain amount of chips in the machining process, referred to as artificial graphite powder.

Seven types of organic modifiers commonly used in montmorillonite

Montmorillonite (MMT) is a huge and cheap natural mineral resource with unique lamellar structure, which is a cost-effective filler for enhancing the properties of polymer materials.

Principle, influencing factors and process of silane coupling agent modified quartz powder

Quartz powder, silicon micropowder and other forms of silica powder used for plastics, rubber and other resins, in order to make the surface compatible with the polymer base material, so as to improve the overall performance and processability of the fill

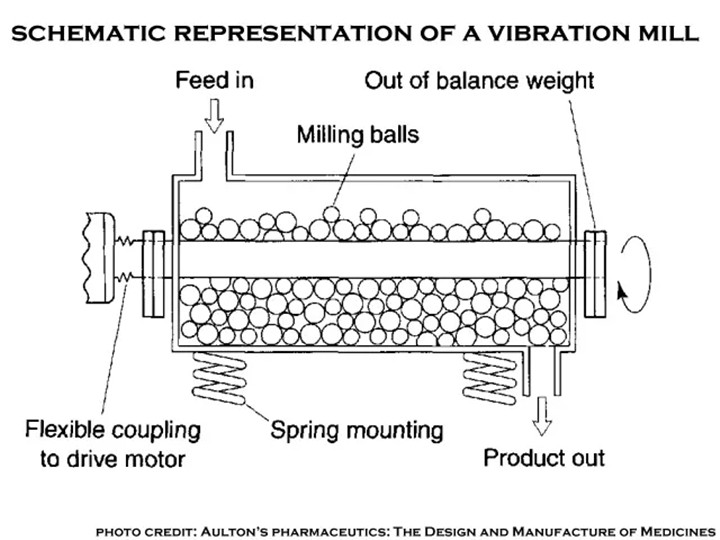

The working principle and characteristics of vibrating mill

There are many types of vibratory mills. According to the vibration characteristics, it can be divided into inertia type and partial rotation type; according to the number of cylinders, it can be divided into single cylinder type and multi-simple type; ac

An article to understand vibration mill

Vibration mill (hereinafter referred to as vibration mill) is one of the ideal equipment for fine grinding or ultrafine grinding. It is an efficient fine grinding and ultrafine grinding equipment developed in recent years. Equipment that uses high frequen

Three typical processes and applicable objects of powder surface modification

The surface modification process varies according to the surface modification method, equipment and powder preparation method. At present, the surface modification processes applied in industry mainly include three categories: dry process, wet process and

Choose surface modifier, mainly look at these 3 aspects!

Modifiers are the key to achieve the intended purpose of powder surface modification, but there are many types and strong pertinence. From the point of view of the interaction between the surface modifier molecules and the surface of the inorganic powder,

Types, principles and processes of inorganic coating of titanium dioxide

In order to meet the requirements for the application performance of titanium dioxide in the actual industry, domestic and foreign scholars have carried out a large number of experimental studies on the inorganic coating of titanium dioxide. Among them, t

What is the appropriate fineness of talc for plastic reinforcement and modification?

Plastic reinforcement modification is an important application field of talc, especially for polypropylene modification in the automotive and home appliance industries. Micronization is the development trend of talc products.

Tourmaline Ultrafine Grinding Technology and Research Progress

When the tourmaline mineral material is applied in powder form, the particle size of tourmaline is required to be less than 3μm in most cases.

Want to promote the application of degradable plastic products on a large scale? Filling modificatio

At present, there are dozens of degradable plastics developed around the world, of which the industrially-produced ones mainly include chemically synthesized PBAT, PLA, and PBS; Mixtures such as starch/PVA, starch/PBS, starch/PLA, etc.

Research progress on crushing and dispersing technology of Chinese herbal medicines

Crushing is an important link in the processing of Chinese medicinal materials and the production process of Chinese medicinal preparations. Traditional Chinese medicine has had fine processing methods such as "water flying", "frustration" and "pound

Research status of preparation of ultrafine non-metallic mineral powders

With the application of non-metallic mineral resources in various fields of economy and society, the development of non-metallic mineral resources has been significantly enhanced. Processing technology puts forward higher requirements, such as ultra-fine.

The energy-saving effect of cement classifier is remarkable

Small footprint, low investment in equipment, short payback period, is a product to replace the traditional cement classifier.

What is the working principle of cement separator?

The cement separator system has simple configuration and low cost, which can greatly increase the output of the mill. Its internal structure is reasonable and the powder selection effect is remarkable. It is a product that improves the product quality of

How to maintain the calcium powder classifier daily?

In order to ensure the long-term operation of the calcium powder classifier, special attention should be paid to the daily maintenance and regular maintenance of the powder classifier.

How much does a large ore ring roller mill cost? Is the investment cost high?

Large-scale ore ring roller mill is mainly for calcite, barite, fluorite, marble, limestone, potassium feldspar, bentonite, phosphate rock, etc. How much is a set of ore ring roller mill? Does it cost a lot of investment?

Lithium mine station is the new outlet of the times, how to choose lithium mine mill?

To choose a good lithium ore mill, not only should the output, fineness, and feed conditions be considered, but also site layout, investment budget, and post-service. Equipment selection is a rigorous matter. OK, you can consult customer service online