NO. 369, Road S209, Huanxiu, Qingdao City, China

Spiral Jet Mill,Jet Mill,Disc Jet Mill

Spiral jet mill and working principle of jet mill

With the development of science and technology, the application of ultra-fine powder in various industries has become increasingly prominent; the ultra-fine pulverizer, an indispensable piece of equipment in the ultrafine powder industry, is also constantly innovating, among which jet pulverizer is an ultra-fine pulverizer One of the most widely used in the air mill, today EPIC Powder introduces the working principle and application of the spiral jet mill (also known as the flat type or disc type) in the jet mill~Spiral jet mill and working principle of jet mill:

After the compressed air is filtered and dried, the airflow is accelerated into supersonic airflow through the Laval nozzle and then enters the crushing chamber. At the same time, the material is accelerated and introduced into the crushing chamber through the feeding pipe nozzle for synchronous crushing. The high-speed jet flow drives the material to make a cyclic movement in the crushing chamber, and the particles and the wall of the fixed target plate impact each other, collide and rub to be crushed. Since there is a jet angle between the jet and the center of the pulverizing chamber, a strong swirling flow is formed in the pulverizing chamber, and the pulverized particles move in the swirling field to obtain a large centrifugal force and are also subjected to the force of the airflow to the center of the pulverizing chamber. The direction of the force is the opposite. When the particle reaches a certain particle size and its centrifugal force is equal to the force of the airflow, then this particle size is the particle size of the separation boundary. The gas is brought out of the pulverizing chamber to become the product. Generally speaking, when the flow rate of the airflow is constant, the airflow force on the particles is also constant. At this time, it is the change of centrifugal force that affects the fineness of the product and the pulverization that affects the size of the centrifugal force. Changes in indoor solids concentrations. Therefore, for the disc jet mill, pulverization and classification are carried out at the same time. The fine particles that meet the particle size requirements are led into the center discharge port of the pulverizer under the drive of the centripetal airflow, and then enter the cyclone separator and the pulse dust collector for collection.

Finished product adjustment:

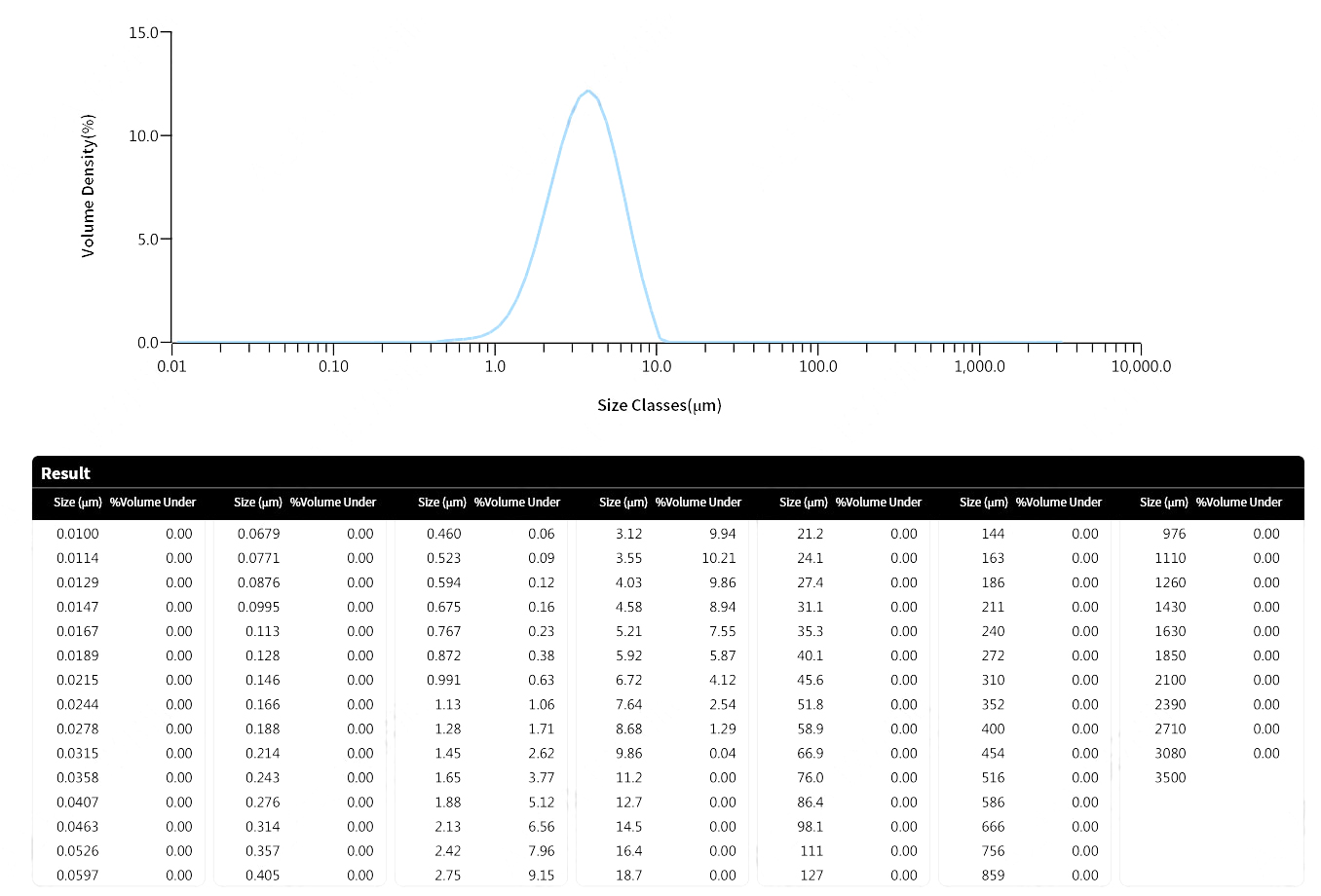

In general, the user can adjust the particle size and output of the finished product by adjusting the crushing pressure of the jet mill and the feeding speed of the feeder.

Under the same working conditions of the same material, the particle size of the finished product is roughly inversely proportional to the output, that is, the finer the particle size requirement, the less the output; the higher the output requirement, the coarser the finished product particle size.

Host material:

The crushing cavity of the crusher is made of high-purity, high-hardness stainless steel 316L; in addition, EPIC Powder can also provide high-hardness, wear-resistant ceramic linings, and special anti-stick linings to meet the requirements of users for different materials and different working conditions

Other parts in contact with the material are made of stainless steel 316L.

Because of its simple structure, convenient disassembly and assembly, and easy operation, the spiral jet mill is popular with users in various industries, especially the pharmaceutical industry with high requirements.

Leave a Comment