NO. 369, Road S209, Huanxiu, Qingdao City, China

talc powder,ball mill

The application of talc powder in plastics

As an additive, modifier, or filler, talc powder has been widely used in papermaking, paint, coatings, ceramics, chemicals for daily use, plastics, food, medicine, and other industries. Talc has the properties of soft texture, easy-grinding, high gloss, low oil absorption, and good transparency.

1.Talc's four properties

1.1 Reinforcement

Talc's unique micro flake-like structure significantly reinforces plastic products. As to processed talc powder, the more complete its flake-like structure is, the more reinforcement it will give to plastic products.

A larger diameter-to-thickness ratio (the ratio of the average diameter of the flake particles to their thickness) can improve the rigidity, impact strength, flexural modulus, and thermal stability of plastic products.

1.2 Insulation

When ultra-fine flake-like talc powder is applied in plastic products, it can be evenly dispersed in the resin in layers. Just like the metal structure in cement products, the plastic added to talc powder will have insulation properties, in addition to maintaining the advantages of plastic itself.

1.3 Nucleation

Talc powder is very slippery, and when it is added to plastic, the opening performance of plastic is improved a lot. Besides, the anti-blocking of plastic film can also be improved. When ultra-fine talc powder (below 1um) is uniformly dispersed in the plastic matrix, it acts as a nucleating agent.

1.4 Aging-resistance

Talc, mica, kaolin, and other silicon-containing materials have infrared-blocking and UV-blocking properties, which enables plastic products to be of insulation and aging resistance.

2. Reasons for choosing talc powder

2.1 Structure of talc

Since the crystal of talc is in a layered structure, it tends to be easily split into scales and has special lubricity. When used in plastic products, it can be uniformly dispersed in the resin in a layered manner. It has good compatibility with the resin as well as mechanical complementarity, which can improve the physical properties of plastic products.

2.2 Silica content in talc

The silicon content in talc powder is an important indicator to measure the grade of talc powder. The higher the silicon content in talc powder is, the higher the purity of talc will be. Thus its application performance will get better and the price will get higher. Customers choose different talc powders according to different performance requirements of plastic products.

2.3 Color of talc

The color of raw talc ore can be white, gray, light red, pink, light blue, light green, and other colors, and it has different degrees of solid luster. This color can improve the appearance and the visual effect of the product.

2.4 Talc’s surface properties

The larger specific surface area and the appearance structure of talc powder will not only affect the amount of additive added but also promote the bonding force between the resin structures, thereby improving the physical properties of plastic products.

3. How talc powder affects plastic performances

3.1 Improving the mold shrinkage of plastic products

With the increase of talc powder content added in plastic, the mold shrinkage of polypropylene decreases gradually. The addition of talc powder increases its viscosity and decreases its creep, therefore the crystallinity of the plastic is reduced; because the talc powder itself has no shrinkage, it reduces the shrinkage of the plastic.

3.2 Surface hardness and surface scratch-resistance of plastic

Surface hardness and surface scratch resistance are the requirements for the use of certain plastic products. The addition of talc powder to polyethylene and polypropylene can effectively improve the surface hardness and surface scratch-resistance of the products.

3.3 Flexural modulus

The addition of white talc powder in flake-like structure to any kind of plastic can significantly increase its flexural modulus. For the general mineral filling, this is the most significant feature of talc powder.

3.4 Tensile strength

The addition of talcum powder in a certain range can increase plastic’s tensile strength. After adding activated talc powder of 1500 mesh into polypropylene, the tensile strength changes. When the content of talc powder in polypropylene is less than 20%, its tensile strength increases slightly. When the content of talc powder in polypropylene is greater than 20%, its tensile strength decreases gradually as the content increases. This is because the further increase of the content of talc powder weakens the intermolecular gravitational force of polypropylene.

3.5 Impact strength

How talc powder affects the impact strength of plastic is similar to the effect of talc powder on plastic’s tensile strength. When the content of a mineral additive in plastic is less than 10%, it affects improving the plastic’s impact toughness. When the content is greater than 10%, the plastic’s impact toughness decreases.

3.6 Deformation temperature

Talc powder has an obvious effect on the thermal deformation temperature of plastic, and can effectively increase the thermal deformation temperature of various plastics, thereby increasing their heat resistance.

4.Application of talc powder in plastic modificatio

4.1 Application in polypropylene (PP)

When polypropylene resin (PP) is added with talc powder, its rigidity, surface hardness, heat creep resistance, electrical insulation, and dimensional stability are improved.

Changes of polypropylene filled with 40% ultra-fine talc powder masterbatch

| Category | Flexural modulus | Thermal heat temperature |

| Change | Increased to 42000kg/cm2 from 16100kg/cm2 | Increased to 88℃ from 62℃(1.82Mpa) |

4.2 Application in polyethylene resin (PE)

When polyethylene resin is added with talc powder, its toughness, heat change temperature, flexural strength, mechanical strength, surface hardness, and smoothness are improved, while its creep tendency is decreased.

4.3 Application in ABS resin (acrylonitrile-butadiene-styrene copolymer)

To improve the existing performance of ABS, by blending ABS and PVC, the automobile instrument board blister sheet made of it is high in strength and toughness, and so is the imitation leather luggage cover. This blended material is filled with ultra-fine talcum powder, which has the advantages of improving the notched impact strength and reducing the manufacturing cost.

4.4 Application in polystyrene resin (PS)

Polystyrene resin has shortcomings such as high brittleness and sensitivity to environmental stress cracking. With the addition of talc powder, it can adjust the rheology, improve the impact toughness, increase the perturbation modulus, and increase the tensile yield strength.

For example: With the addition of 40% superfine talc powder or talc powder masterbatch, the perturbation modulus increases from 23800kg/cm2 to 58800kg/cm2, and the tensile strength increases from 336kg/cm2 to 385kg/cm2.

4.5 Application in polyvinyl chloride resin (PVC)

When the talc powder with an average particle size of 5 microns (2000 mesh) is added to PVC by 40-50% volume, the plastic’s yield strength is even higher than the original breaking strength, which has a significant reinforcement effect on the PVC; the unnotched impact strength is 15% by weight and there is basically no decrease, and the notched impact strength is reduced; it significantly increases the flexural modulus.

5. Comparison of the effect of talcum powder and calcium carbonate on plastic modification

5.1 Shape

The shape of talcum powder is flake-like, and it has higher rigidity with good performance of dimensional stability and heat resistance, and it has a good reinforcement effect. Calcium carbonate powder is generally granular, so its rigidity and other performances are not as good as talc powder.

5.2 Nucleation

Talc has a nucleation effect on polypropylene, while calcium carbonate has no obvious effect in this aspect.

Comparison of the effect of calcium carbonate and talc powder on plastic modification

| Content | 20% Calcium carbonate | 20% Talc powder |

| Tensile strength | 27.8Mpa | 29Mpa |

| Flexural strength | 40Mpa | 42Mpa |

| Flexural modulus | 2000Mpa | 1300Mpa |

| Model shrinkage | 0.87 | 0.82 |

6. How to use talc powder

6.1 Direct addition of the powder

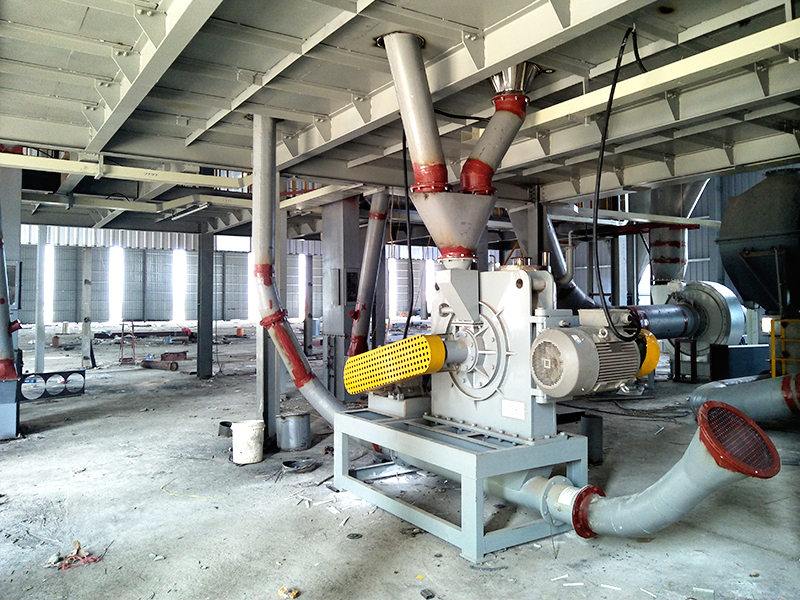

The talc powder is directly mixed with the plastic raw material and then extruded and pelletized by a twin-screw extruder to become modified plastic raw materials. This is a common method and the most economical method.

6.2 By means of Carrier-free masterbatch

The talc powder is made into a kind of loose particles without a carrier through a special process, and then this kind of particles is mixed with plastic raw materials, and granulated into modified plastic raw materials by a twin-screw extruder.

6.3 By means of filling masterbatch

The talc powder and the plastic carrier are mixed and granulated by an extruder to form a high-content masterbatch. This masterbatch can be directly mixed with plastic raw materials, and the finished product can be processed by extrusion and injection.

7. Points for attention for the use of talc powder

7.1 The surface activation treatment of talc powder is necessary, and this process is mainly to improve the compatibility between talc powder and plastic raw materials and increase its modification performance. Different surface treatment agents should be selected and applied for different plastics.

7.2 The dispersibility of talc powder in plastic raw materials. Under the same formula, the dispersibility of talc powder in plastic raw materials has a great effect on the final physical and chemical properties of the modified material. The production process should be strictly controlled. The main factors affecting the dispersion of talc powder in plastic raw materials are formula, temperature, output, and technological process. In addition, when the amount of talc powder added is large, stepwise addition can be used to achieve a good dispersion effect.

Talc powder is a non-metallic mineral with a very wide range of applications. With the ongoing improvement of social science and technology development, the application of talc powder is facing more opportunities and challenges. The application demand for talc powder in various industries is increasing, and the talc market has a great prospect.

Leave a Comment