A non-metallic mineral processing enterprise in Poland has successfully purchased a new heavy calcium carbonate (GCC) production line. This strategic investment was driven by the client’s goal to seek an advanced coating modification process. It’s aiming to enhance the value and functionality of their calcium carbonate products for high-end applications in industries such as plastics, paints, and sealants.

After an extensive market evaluation, the Polish client identified Poudre EPIC as a preferred partner through strong recommendations from industry peers. EPIC’s proven expertise in non-metallic ore ultrafine processing and its specialized knowledge in modification technology were the decisive factors. The collaboration began with a thorough testing phase at EPIC’s application center. The client submitted raw material samples, which underwent rigorous processing trials on EPIC’s pilot-scale equipment. These tests were crucial for verifying the final product’s quality. They optimize the modification formula, and guaranteeing the production line’s performance metrics. The successful outcomes of these two comprehensive test cycles built significant confidence, leading the client to finalize the order.

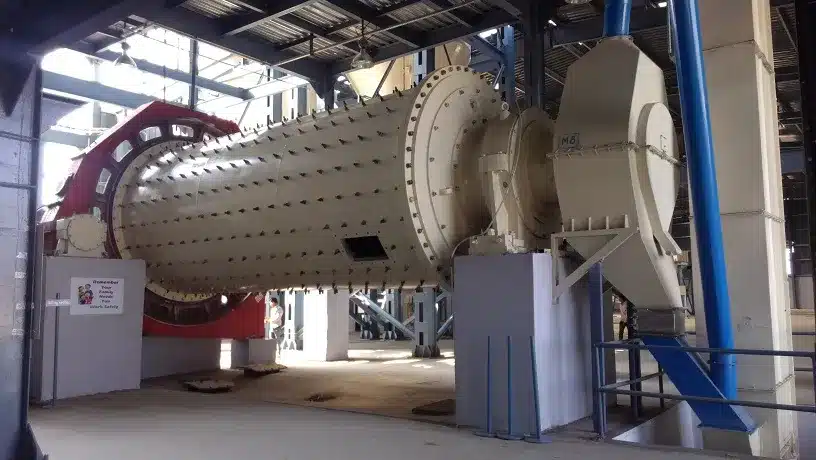

The commissioned system is a fully integrated ball-milling, classification, and modification production line, engineered for a capacity of 750 kg per hour. The calcium carbonate production process begins with raw GCC with a feed size of 10μm. This material is fed into an efficient broyeur à boulets for comminution. It’s followed by a precision classificateur d'air that ensures a consistently fine and tightly controlled product size of D97: 10μm. The finely classified powder is then pneumatically conveyed to the surface modification stage. In this key unit, specialized coupling agents are uniformly coated onto the GCC particles under controlled temperature and shear conditions. This coating process transforms the inorganic powder into a functional material. It can improve the compatibility with organic polymers. Thereby it enhances dispersion, mechanical strength, and overall performance in the final composite products.

Paramètres techniques :

Matière première:CCG

Granualité :D97:10 μm

Sortir:750kg/h