3ローラーコーティング機

この連続粉体表面コーティングシステムは、ドイツのノウハウと中国の設備をベースに設計されており、炭酸カルシウム(GCC、PCC)、カオリン、タルク、マイカ、グラファイト、硫酸バリウム、ホワイトカーボンブラック、水和マグネシウム、酸化亜鉛、酸化アルミニウムなどのさまざまな粉体のコーティングに使用できます。また、アルミネートカップリング剤、チタン酸塩カップリング剤、シランカップリング剤、ステアリン酸などのさまざまな固体/液体コーティング剤にも適しています。

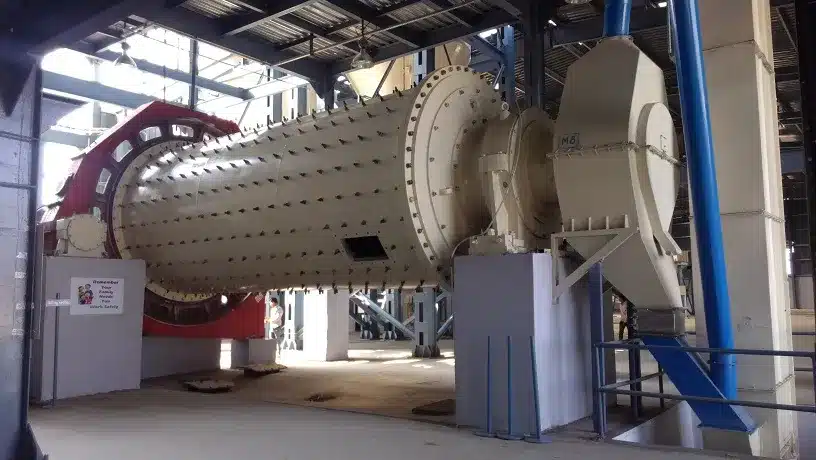

動作原理

この連続粉体表面コーティングシステムは、ドイツのノウハウと中国の設備をベースに設計されており、炭酸カルシウム(GCC、PCC)、カオリン、タルク、マイカ、グラファイト、硫酸バリウム、ホワイトカーボンブラック、水和マグネシウム、酸化亜鉛、酸化アルミニウムなどのさまざまな粉体のコーティングに使用できます。また、アルミネートカップリング剤、チタン酸塩カップリング剤、シランカップリング剤、ステアリン酸などのさまざまな固体/液体コーティング剤にも適しています。

コーティング機は3つの混合室で構成されています。高速回転により、これらの特殊形状の混合室内に大きな渦流が形成されます。粉体とコーティング剤は、この高速気固渦流の中で混合されます。表面コーティング機能と粒子分散機能の両方を備えたこのコーティング機は、様々な粒度の粉体に適しており、見かけ比重が小さく、容積重量比が大きい材料に対しても、優れたコーティング効果を発揮します。

自動温度制御システムにより、コーティング剤が液体に溶解し、未コーティングの粉末と混合する際に、安定した高温が確保されます。粉末とコーティング剤の加熱と冷却は1台の機械で完結するため、独立した冷却システムは必要ありません。

コーティング剤の利用率が高く、粉体塗装率が高く、活性度が高く、エネルギー消費量が少なく、最終塗装製品における凝集物が非常に少ない。システム全体は負圧下で稼働し、粉塵の発生がなく、労働強度も低い。

機能と利点

- 3つの回転ローターにより内部渦を変化させ、粉体表面改質を実現します。

- 成熟した技術、低投資、ステアリン酸コーティングに適しています。

- 自己摩擦により熱が発生するため、加熱装置が不要で、補助機械が少なくなり、運転コストが低くなります。

- 325~3000メッシュの粉体塗装に適しています。

- 出力範囲:11kW~225kW、最大出力:6t/h。

- 空気量が少なく、特に微粉の分散性が悪く、改質剤の量が多い。

- 自己摩擦発熱は環境要因の影響を受けやすく、改質温度の制御が困難です。

- デッドゾーンがありコーティング率が低い。

関連製品

技術的パラメータ

CRMシリーズ3ローラーコーティング機の技術的パラメータ

| モデル | モーター(kW) | 回転数(RPM) | 細かさ(メッシュ) | 容量(kg/h) | 温度(℃) |

|---|---|---|---|---|---|

| CRM-3 | 18.5x3 | 4500 | 325-3000 | 500-1500 | 80-120 |

| CRM-6 | 37x3 | 2700 | 325-3000 | 1200-3700 | 80-120 |

| CRM-9 | 75x3 | 2000 | 325-3000 | 2000-7500 | 80-120 |

プロジェクト事例

最新ニュース

お問い合わせ

弊社の専門家が 6 時間以内にお客様に連絡し、機械とプロセスに関するお客様のニーズについてご相談させていただきます。

工場住所:

いいえ。 369、Road S209、環秀、青島市、中国