ハイテク素材

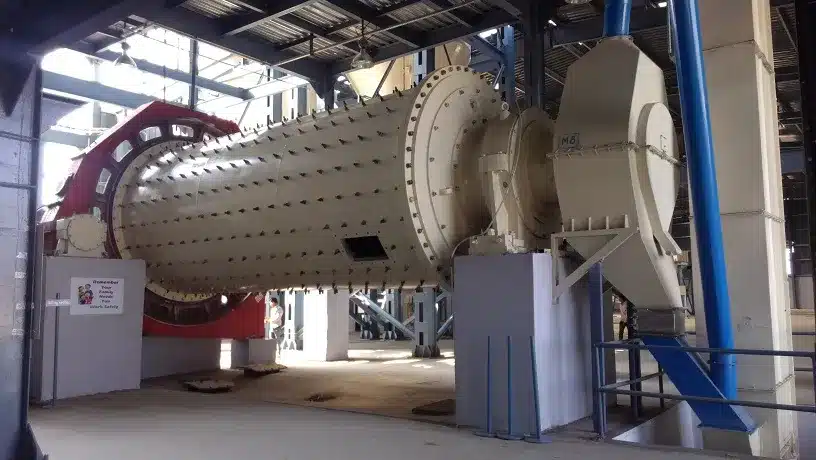

科学技術の急速な発展は、様々な新素材の継続的な出現をもたらし、新素材の出現もまた技術の発展を促進しています。粉末は、どんなに微細であっても、どんな形状であっても、材料として利用可能です。粉末加工技術は、材料の研究と応用において重要な役割を果たしています。EPIC Powderテクノロジーは、超精製、超高純度、特定の機能、そして安全性と環境保護を目標に、新素材産業に最先端のフルプロセスサービスを提供することを目指しています。

協力クライアント

プロジェクト事例

当社は、以下のパフォーマンス指標を満たすプロセスと機器を提供できます。

- 当社では、蒸気運動エネルギー研削、ナノ乱流研削、超音速気流研削など、独自に開発した新技術を使用して、お客様がマイクロメートルからナノメートルスケールまでのブレークスルーを達成できるよう支援しています。

- 材料内の敏感な要素を制御する必要性に応じて、材料と接触する主要コンポーネントを保護するために複数の材料を使用し、材料の純度を大幅に保証します。

- 粒子の形態、粒度分布、分散など、特定の材料機能要件を満たすために顧客のニーズに基づいてカスタマイズされたソリューション。

- 揮発性、腐食性、毒性、有害物質のカスタマイズされた生産計画を採用することで、物質の漏洩による人体や環境への害を大幅に軽減します。

- 装置の内部ライニングは、生産ニーズに応じてアルミナやジルコニアなどのセラミック材料で作ることができ、不純物の摂取を減らすことができます。

粉末製造工程では自動化とインテリジェント制御方式を採用し、可燃性および爆発性物質に対しては不活性ガス循環保護などの対策を講じ、安全で制御可能な生産操作を確保しています。

お問い合わせ

弊社の専門家が 6 時間以内にお客様に連絡し、機械とプロセスに関するお客様のニーズについてご相談させていただきます。

工場住所:

いいえ。 369、Road S209、環秀、青島市、中国