Dans la première partie, nous avons dévoilé les secrets de plastiques plus résistants et plus économiques, en explorant les rôles fondamentaux du carbonate de calcium, du talc et de la wollastonite. Mais l'univers des charges plastiques ne s'arrête pas là. Découvrons maintenant comment des matériaux comme le kaolin, le mica et la silice peuvent être la clé de votre prochain composé plastique innovant.

Kaolin

Le kaolin (Al₂O₃·2SiO₂·2H₂O), un type de poudre minérale argileuse également connue sous le nom d'argile à poterie, d'argile blanche ou de kaolin, est un silicate feuilleté principalement composé de silicate d'aluminium hydraté. Il a une texture douce et lisse, avec une densité de 2,2–2,6 g/cm³ et une valeur de pH de 5–6Il est non toxique et possède des propriétés ignifuges. Le kaolin offre une meilleure aptitude à la transformation que le carbonate de calcium, ce qui permet de le mouler même lorsque la quantité de remplissage atteint trois fois le poids de la résine. En revanche, le carbonate de calcium devient plus difficile à transformer avec un rapport de remplissage de 1:1.

En tant que charge plastique, le kaolin offre d'excellentes propriétés d'isolation électrique, ce qui le rend idéal pour les gaines de fils isolées en PVC, les câbles en PE et PP, ainsi que les films composites. Par exemple, l'ajout de kaolin 10% (en poids) au PVC peut multiplier par 5 à 10 les performances d'isolation électrique. Le kaolin peut également être incorporé dans les films composites à base de polystyrène pour la production de papier d'impression. Dans les polyesters et les résines époxy, il permet d'ajuster la viscosité et les performances de mise en œuvre tout en améliorant la résistance à l'usure. De plus, le kaolin agit comme agent de nucléation pour le PP et présente certains effets ignifuges.

Le taux d'ajout typique de kaolin dans les plastiques varie de 5% à 60%, avec une taille de particule de 100 mailles ou plus fin. Il est important de noter que le kaolin est très hygroscopique ; son stockage doit donc empêcher l'absorption d'humidité et l'agglutination. Avant utilisation, le kaolin doit être séché pour ne pas altérer la qualité du plastique. Parfois, un traitement de surface avec des agents lipophiles est appliqué pour améliorer sa compatibilité avec les plastiques.

Mica

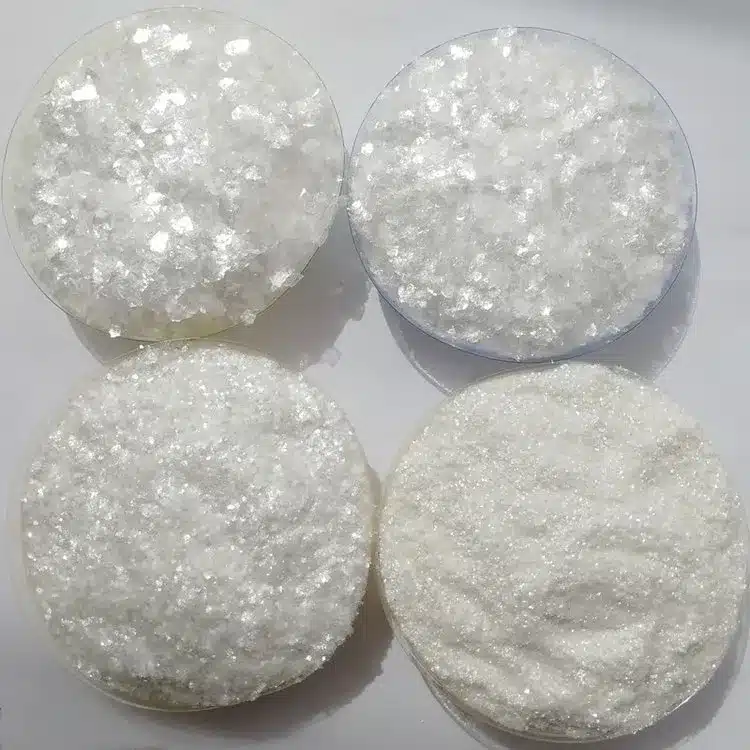

Le mica a une composition complexe, étant un matériau stratifié aluminosilicate hydraté Minéral contenant de l'aluminium, du potassium, du lithium, du magnésium, du fer et d'autres éléments. Utilisée comme charge, la poudre de mica est produite par broyage et traitement de fragments de mica naturel. Sa granulométrie est généralement de 8–10 μm et un rapport hauteur/largeur d'environ 30, présentant une structure feuilletée typique avec un éclat vitreux. Sa teneur en eau varie de 1.0% à 4.2%, et il est non toxique, ce qui le rend adapté à nourriture-produits de contact.

La poudre de mica peut être utilisée pour le remplissage de plastiques thermoplastiques tels que le PE, le PP, le PVC, le PA, l'ABS et les polyesters, ainsi que de plastiques thermodurcissables comme l'EP (résine époxy) et le PF (résine phénolique). Le taux d'ajout est généralement le suivant : 10%–40%, avec une taille de particule de 100–325 meshEn tant que charge plastique, le mica améliore considérablement le module de traction et de flexion des produits plastiques, offrant une excellente isolation électrique, une résistance à la chaleur, une stabilité dimensionnelle, une résistance à l'humidité et une résistance à la corrosion. Son principal inconvénient est son coût relativement élevé.

diatomite

La diatomite est un fossile formé par le dépôt d'algues unicellulaires au fond des océans ou des lacs. Son principal composant est le SiO₂. Elle est poreuse, légère et facile à réduire en poudre. Elle se présente sous forme de poudre blanche ou jaune clair, dont la granulométrie est de 25–40 μm et une densité de 1,6–2,3 g/cm³.

La diatomite est un matériau de remplissage léger de haute qualité, adapté au PVC, aux polyoléfines (PO) et aux plastiques thermodurcissables. Elle sert également d'agent anti-adhérent dans les composites de construction légers, phoniques et thermiques. Cependant, son taux d'absorption d'huile et de résine est relativement élevé.

Noir de carbone

Le noir de carbone est produit par la combustion incomplète d'hydrocarbures dans des conditions contrôlées. Il existe en plusieurs types, classés selon leur méthode de production : noir de canal, noir de four et noir thermique, entre autres. Ajouté aux polymères, le noir de carbone protège non seulement contre la photodégradation et l'oxydation thermique, mais renforce également la rigidité des produits plastiques.

La finesse du noir de carbone affecte les performances du produit : des particules plus fines offrent une noirceur plus élevée, une meilleure protection contre les UV, une meilleure résistance au vieillissement et une résistivité superficielle plus faible. Cependant, des particules plus fines peuvent être plus difficiles à disperser. Pour les applications de charge, on utilise généralement du noir de four à particules plus grosses, avec une granulométrie typique de 25–75 μm.

Silice

La silice (SiO₂) est une poudre de roche classée en poudre de quartz et en poudre de silice. La poudre de silice naturelle est principalement utilisée dans les résines thermodurcissables, telles que les polyesters insaturés et les résines époxy, pour la production d'onyx et de marbre artificiels.

La silice peut également être synthétisée, communément appelée noir de carbone blanc. C'est une charge renforçante, deuxième après le noir de carbone, qui procure un effet matifiant et améliore l'isolation électrique et la dureté des plastiques. Ses principaux inconvénients sont une faible fluidité et une viscosité élevée.

Poudre épique

Poudre épiquePlus de 20 ans d'expérience dans l'industrie des poudres ultrafines. Nous promouvons activement le développement futur des poudres ultrafines, en nous concentrant sur les procédés de concassage, de broyage, de classification et de modification de ces dernières. Contactez-nous pour une consultation gratuite et des solutions personnalisées ! équipe d'experts se consacre à fournir des produits et services de haute qualité pour optimiser la valeur de vos opérations de traitement de poudre. Epic Powder : votre expert de confiance en traitement de poudre !