Cet article explore le rôle essentiel de la poudre d'aluminium dans la fabrication de blocs de béton cellulaire, un matériau de construction léger et économe en énergie. Plus précisément, nous examinerons comment la poudre d'aluminium permet la formation de la structure poreuse caractéristique du matériau et passerons en revue les équipements de broyage proposés par Epic Powder, spécialiste des technologies de traitement des poudres ultrafines.

Q1 : Pourquoi la poudre d’aluminium est-elle utilisée dans la fabrication de blocs de béton cellulaire ?

R : La poudre d'aluminium est un ingrédient essentiel car elle réagit chimiquement avec la silice et la chaux vive lors de la production. Cette réaction libère de l'hydrogène gazeux, qui crée des millions de minuscules bulles dans le mélange. Ces bulles forment une structure interne hautement poreuse dans le bloc final durci.

Q2 : Comment la poudre d'aluminium est-elle ajoutée au processus de production ?

R : La poudre (ou pâte) d'aluminium est d'abord ajoutée à une cuve de mélange spécialisée pour former une pâte. Après un mélange minutieux, cette pâte est dosée avec précision, puis ajoutée au malaxeur principal, où elle se combine avec d'autres matières premières comme la chaux vive, le gypse et les cendres volantes.

Q3 : Quel est le principal avantage de la création de ces bulles (pores) ?

R : Le principal avantage est une réduction considérable du poids. Grâce à leur structure poreuse, les blocs de béton cellulaire sont très légers, avec une masse volumique typique de 500 à 700 kg/m³. Cela représente environ :

- 1/4 à 1/5 du poids des briques d'argile pleines.

- 1/5 du poids du béton ordinaire.

L'utilisation de ces blocs peut réduire le poids total de la structure d'un bâtiment de plus de 40% par rapport à une construction ordinaire en briques et béton.

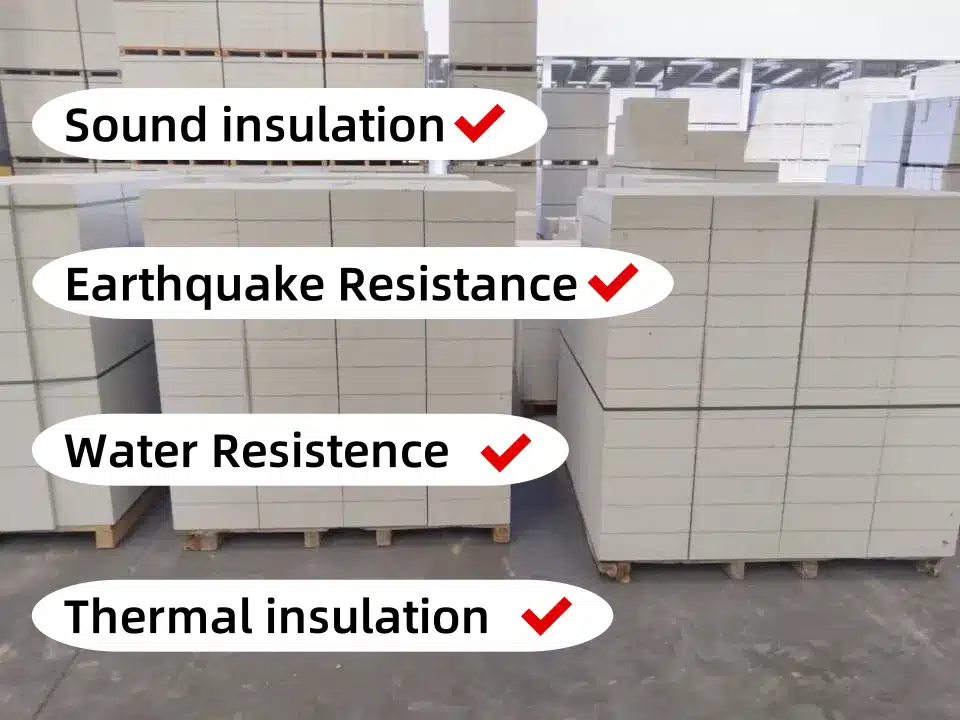

Q4 : Outre leur légèreté, quels autres avantages présentent ces blocs ?

A : La structure poreuse unique offre plusieurs avantages clés :

1. Isolation acoustique : La structure interne, remplie de bulles d'air fermées, offre une excellente absorption acoustique. Un mur de 100 mm d'épaisseur peut atteindre une isolation acoustique de 41 dB.

2. Résistance aux tremblements de terre : Leur légèreté et leurs bonnes performances structurelles globales signifient qu'ils génèrent des forces d'inertie plus faibles lors d'un tremblement de terre, améliorant ainsi la résilience sismique du bâtiment.

3. Isolation thermique : Leur grand nombre de pores et de micropores en font d'excellents isolants thermiques. Leur coefficient de conductivité thermique est de 0,11 à 0,16 W/mK, soit seulement 1/4 à 1/5 de celui de la brique en terre cuite. Par exemple, un mur en béton cellulaire de 20 cm d'épaisseur offre une isolation similaire à celle d'un mur en briques de terre cuite pleines de 49 cm d'épaisseur.

4. Résistance à l'eau et anti-perméabilité : Les petits pores indépendants absorbent et transmettent l'humidité très lentement. Il faut environ cinq fois plus de temps à ces blocs pour être complètement saturés d'eau que les briques en terre cuite. Dans les pièces comme les salles de bains, les carreaux peuvent être posés directement sur le mur après un simple traitement d'interface.

Q5 : Quel type spécifique de poudre d'aluminium est utilisé ?

R : On utilise généralement une poudre d'aluminium très fine, souvent avec une finesse standard de d97 63 μm (ce qui signifie que 97% des particules ont une taille inférieure à 63 micromètres). Cette grande surface est essentielle pour une réaction chimique efficace et uniforme.

Solutions de broyage par Epic Powder

La production de poudre d'aluminium présentant la finesse et l'uniformité requises pour les applications de béton cellulaire exige une technologie de broyage avancée. Epic Powder propose des solutions sur mesure, utilisant des broyeurs à boulets et des broyeurs à vibrations pour obtenir des granulométries précises, telles que la norme industrielle d97 ≤ 63 µm.

Les broyeurs à boulets offrent une capacité de broyage élevée, adaptée à la production à grande échelle, garantissant une qualité constante grâce aux forces d'impact et de cisaillement. Les broyeurs à vibrations, reconnus pour leur efficacité énergétique et leur conception compacte, sont idéaux pour obtenir des distributions de particules ultrafines et étroites. Ces deux méthodes permettent de produire la poudre d'aluminium hautement réactive, essentielle à la formation optimale des pores dans les blocs de béton cellulaire.

À propos d'Epic Powder

Machines à poudre Epic est un fournisseur leader de systèmes de broyage et de classification, spécialisé dans les solutions de réduction granulométrique pour une large gamme de poudres industrielles, notamment les métaux non ferreux comme l'aluminium. Fort d'une solide expertise en pneumatique, classification, le fraisage mécanique et l'intégration de systèmes, Epic Powder accompagne ses clients dans des secteurs tels que la construction, la chimie et les nouveaux matériaux. Grâce à ses équipements de pointe et à sa connaissance approfondie des procédés, l'entreprise est un partenaire privilégié des fabricants cherchant à améliorer les performances de leurs produits grâce à des poudres aux propriétés contrôlées.