Why Jet Milling is Critical for High-Performance Iron Phosphate

Iron phosphate (FePO₄) is the cornerstone precursor for lithium iron phosphate (LiFePO₄) cathodes, but its electrochemical performance hinges on precise particle size control. While synthesis methods like ammonia precipitation or sodium-based reactions yield varying initial particle sizes (50 nm–10 μm), most industrial applications demand a tight distribution of 0.5–2 μm. This is where EPIC Powder’s advanced fluidized-bed jet milling—bridge the gap between synthesis and functionality.

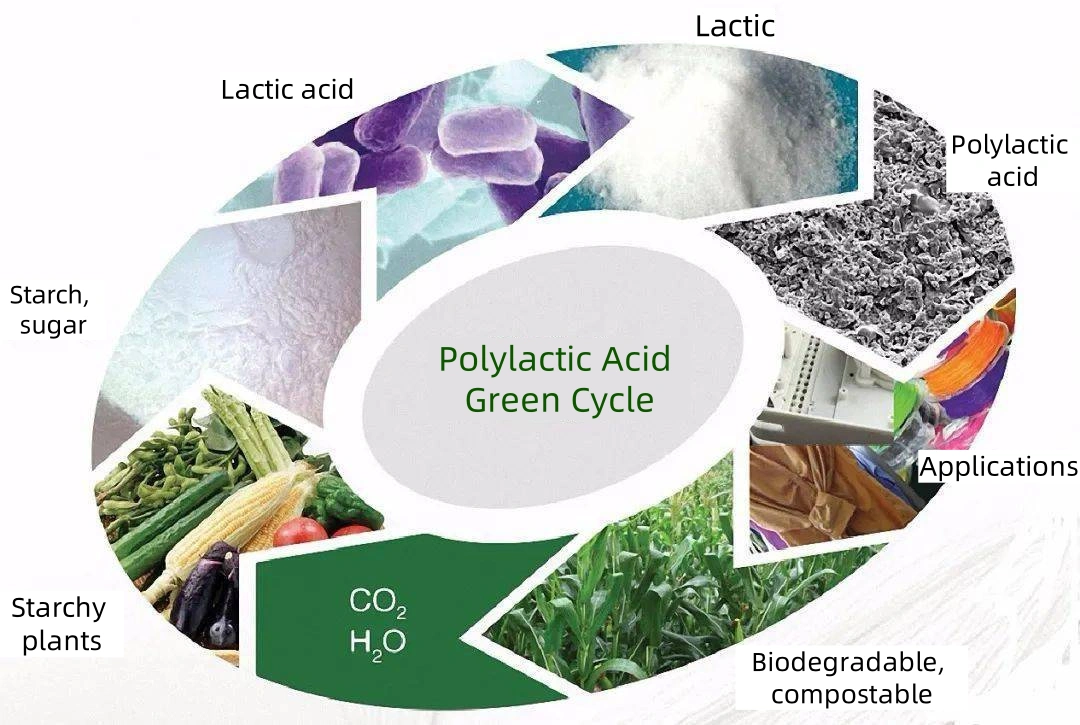

What is iron phosphate?

Iron phosphate is a chemical compound that combines iron, phosphorus, and oxygen. It exists in various forms, with the most common being FePO4 (ferric phosphate or iron(III) phosphate) and LiFePO4 (lithium iron phosphate). It’s used in diverse applications, including as a pesticide (particularly for slugs and snails), a metal treatment coating, a pigment in paints, and as a component in lithium-ion batteries.

Iron Phosphate in Battery Applications

Iron phosphate (FePO₄) serves as the critical precursor material for lithium iron phosphate (LiFePO₄ or LFP) cathodes, which have become increasingly vital in energy storage and electric vehicle batteries due to their superior safety, long cycle life, and cost-effectiveness compared to nickel-manganese-cobalt (NMC) alternatives. The performance of the final LFP cathode is intrinsically linked to the quality of its FePO₄ precursor, particularly in terms of particle size distribution, purity, crystallinity, and morphology. As battery manufacturers push for higher energy densities and faster charging capabilities, the demand for precisely engineered iron phosphate materials has intensified, placing greater emphasis on optimized production processes and stringent quality control measures.

Three Major Process Routes

The production of battery-grade iron phosphate primarily employs three distinct process routes, each with unique characteristics:

Ammonia Process utilizes ammonia water for pH adjustment, with ferrous sulfate and phosphoric acid as raw materials and hydrogen peroxide as the oxidant. This process yields high-purity products (≥99.5%) with stable Fe/P ratio around 0.97, typically forming 50-500nm agglomerates. While the byproduct ammonium sulfate can be recycled, the process requires significant washing water (approximately six times the filter cake mass).

Sodium Process employs sodium hydroxide or sodium carbonate as precipitating agents, generating low-value sodium sulfate byproducts. Although this method reduces washing water consumption to only 20-30% of the ammonia process, the final product contains higher sodium residue (300-500ppm) which adversely affects battery performance. The particles generally consist of dense 1-10μm crystals.

Phosphoric Acid Process directly uses excess phosphoric acid as reaction medium, offering simplified operation and minimal wastewater. However, it consumes large quantities of phosphoric acid, often resulting in phosphorus excess and lower compaction density (<1.4g/cm³), with relatively broad particle size distribution (0.1-5μm).

Table 1: Key Parameter Comparison of Three Processes

| Parameter | Ammonia Process | Sodium Process | Phosphoric Acid Process |

| Purity | ≥99.5% | ~99% | 98-99% |

| Particle Size | 0.05-0.5μm | 1-10μm | 0.1-5μm |

| Water Usage | High | Medium | Low |

| Application | Premium Batteries | Mid-range Batteries | Basic Applications |

Critical Quality Control Requirements

Battery-grade iron phosphate must meet stringent quality standards:

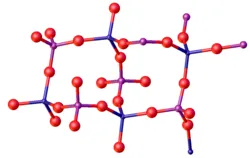

Chemical composition requires iron content of 36.0-36.5%, phosphorus content of 20.5-21.0%, and Fe/P molar ratio between 0.96-0.98. Impurity elements must remain below 50-400ppm individually, with sulfate content under 0.5%.

Physical specifications include moisture content below 1% and pH value between 2.5-4.0. Laser diffraction analysis should show D50 values controlled within 0.5-2μm, while BET surface area must range 15-35m²/g.

Structural characteristics demand XRD patterns matching standard reference cards, with SEM observations revealing uniform spherical or near-spherical particles.

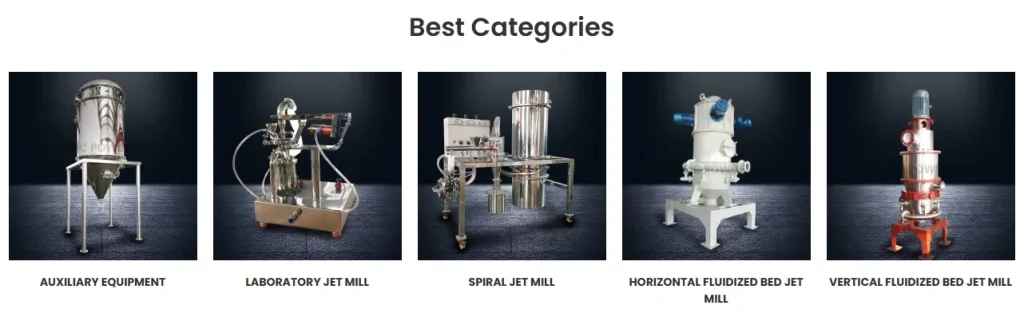

The Critical Role of Jet Milling Technology

EPIC Powder’s jet milling technology effectively addresses particle size control challenges across all processes:

For ammonia process products, the technology gently disperses nanoparticle agglomerates without damaging primary particles, stabilizing D50 at 0.8-1.2μm. Sodium process materials benefit from size reduction of large 3-10μm particles down to 1.2-1.8μm while maintaining specific surface area between 18-22m²/g. The phosphoric acid process achieves narrow particle distribution of 0.8-1.8μm through precise classification, improving compaction density by over 30%.

The Jet Milling Advantage: From Synthesis to Battery Grade

Traditional ball milling can introduce metallic contamination and heat-sensitive phase changes, but jet milling leverages high-purity gas (N₂ or air) to achieve collision-based fragmentation without contact. For example, sodium-derived FePO₄ often forms dense 5–10 μm crystals that require refining to 1 μm with a narrow PSD. EPIC’s trials show a single pass through a QYF-350 jet mill reduces D50 from 8.2 μm to 1.3 μm while maintaining >99.5% purity—critical for avoiding lithium battery capacity fade. Implementation of jet milling has delivered significant product enhancements:

Ammonia process products show reduced electrode capacity variation from 8-10mAh/g to just 2mAh/g. Sodium process materials demonstrate 10-15% improvement in electrochemical capacity. Phosphoric acid process products achieve increased compaction density from 1.8g/cm³ to 2.1g/cm³.

As performance requirements for LFP batteries continue to escalate, precision jet milling has become an essential process step for iron phosphate precursor production. EPIC Powder’s solutions enable manufacturers to meet the exacting demands of premium battery materials while maintaining cost efficiency.

Epic Powder

As a leading innovator in powder processing technology, EPIC Powder delivers excellent jet milling solutions tailored specifically for iron phosphate production. Contact our engineers for a free process evaluation and discover how our patented MQW series jet mills can boost your battery material performance while reducing operating costs. Request your customized solution at epic-powder.com