Quartz Ore Crushing and Grinding Technology and Key Points

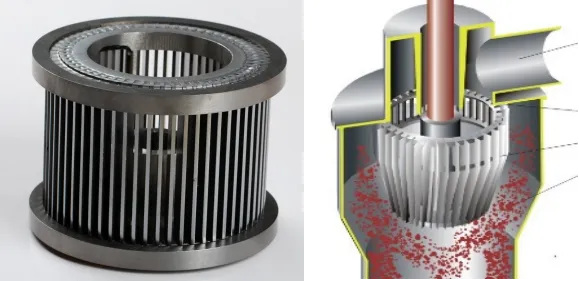

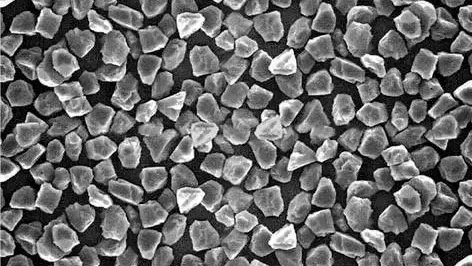

To purify quartz ore, the raw material must first be crushed and classified as a pretreatment step. The purpose of this is to achieve the initial separation of quartz from associated minerals and to provide raw materials with a suitable particle size range for subsequent processing and purification. Quartz Crushing The goal of crushing is […]

Quartz Ore Crushing and Grinding Technology and Key Points Read More »