Limestone is a sedimentary rock primarily composed of calcite (calcium carbonate, CaCO3). It is typically formed in marine or lake environments and precipitated through biological and chemical processes. The characteristics and types of limestone are as follows: • Color: Generally gray, white, yellow, brown, etc., depending on the impurities it contains.

• Texture: The texture is usually uniform and fine, but it may also contain fossils or other rock fragments.

• Structure: Limestone can have granular, mud-crystalline, bioclastic, or other structures.

• Hardness: Its Mohs hardness is about 3, making it relatively soft.

• Solubility: It is easily soluble in acid, producing carbon dioxide bubbles.

According to various standards, limestone can be processed to produce a variety of products, which are widely used in different industries. Below are several major products derived from limestone ore processing and their applications:

1. Portland Cement

After limestone is crushed, ground, and mixed with clay and other auxiliary materials, the mixture is further ground to an appropriate particle size. The powdered materials are sent to a rotary kiln and calcined at a high temperature (about 1450°C) to form cement clinker. After adding an appropriate amount of gypsum, the clinker is ground into a very fine powder, resulting in the finished cement.

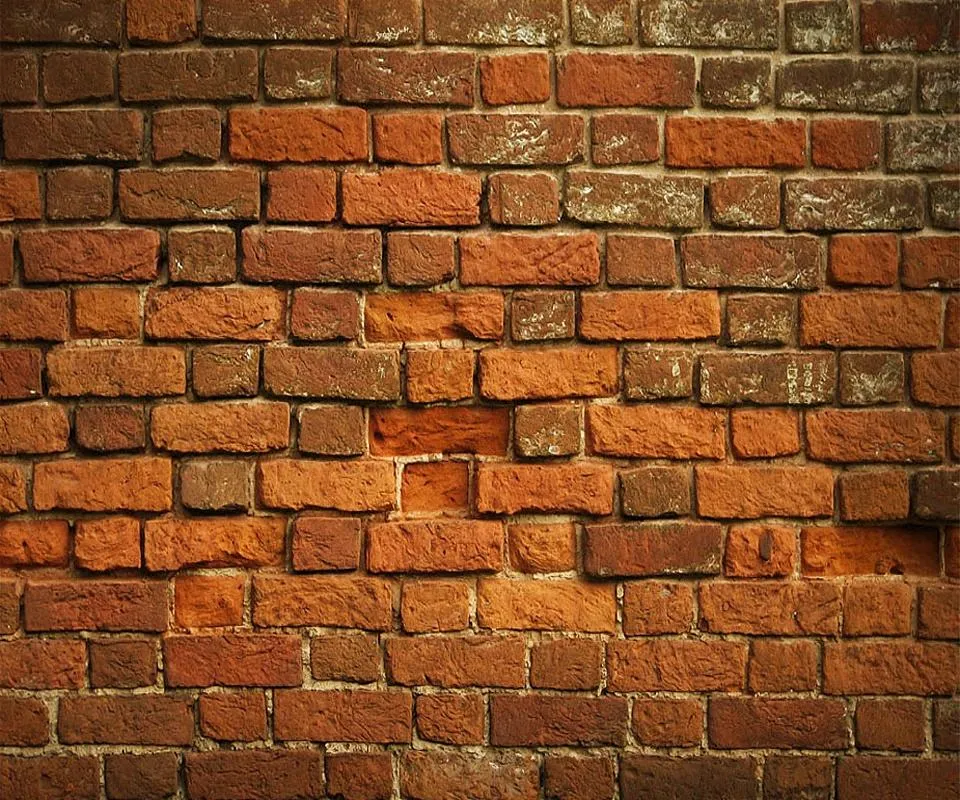

2. Building Stone

Limestone is used as a basic material in construction, such as for foundations and walls, particularly in civil buildings. Its affordability helps enhance structural stability and reduce costs.

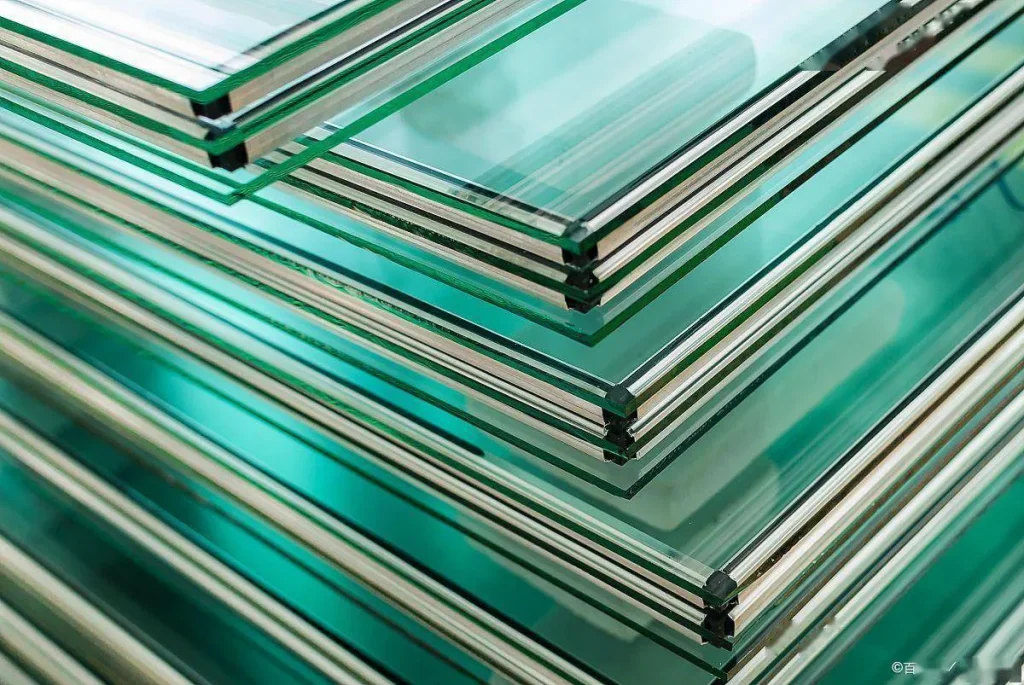

3. Glass

In glassmaking, limestone is mixed with soda ash (Na2CO3) and quartz (SiO2) in precise proportions and melted at high temperatures to react and form calcium silicate (CaSiO3) and carbon dioxide (CO2), thus producing ordinary glass.

4. Iron Ore Smelting Aid

Limestone acts as a desulfurizer in the iron smelting process, helping to remove silicon dioxide (SiO2) from iron ore. It forms low-melting calcium silicate (CaSiO3), which makes it easier to remove impurities from molten iron.

5. Quicklime (CaO)

When limestone is calcined and decomposed at high temperatures (900°C – 1300°C), it produces calcium oxide (CaO), or quicklime. This process typically occurs in a vertical furnace or rotary kiln. Quicklime is used as a dehydrating agent in building materials, desiccants, explosives, and in food, medicine, and other industries.

6. Calcium Hydroxide (Ca(OH)2)

Also known as slaked lime or hydrated lime, calcium hydroxide is produced by adding water to quicklime. This step takes place in a specially designed digester to control temperature and humidity. It is used to create Bordeaux mixture, improve acidic soil, treat acidic wastewater, and more.

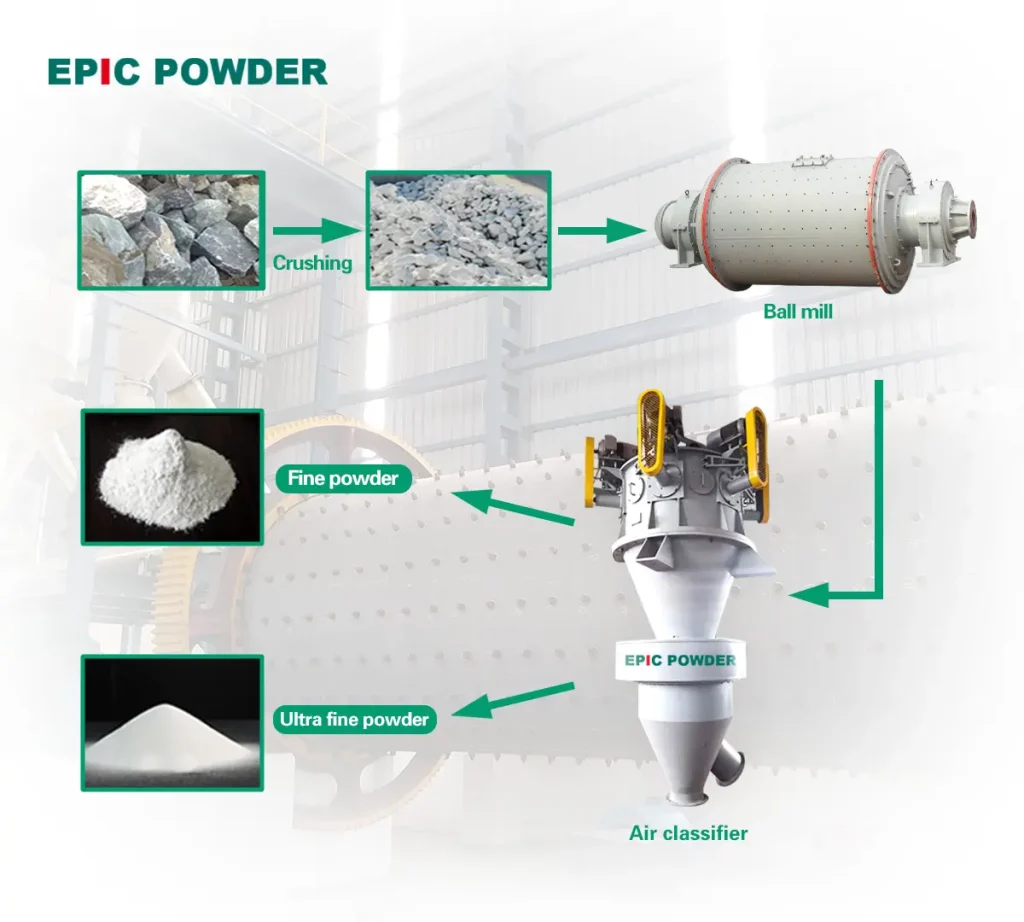

7. Ground Calcium Carbonate (GCC)

Limestone mined from the quarry is initially crushed, then further ground into fine powder by a ball mill or other grinding equipment. The powder is graded using an air separator to ensure the required particle size distribution. Due to its high chemical purity, inertness, and thermal stability, it is widely used as a filler in industries such as papermaking, plastics, rubber, and coatings.

8. Precipitated Calcium Carbonate (PCC)

Chemical Preparation: High-purity limestone is used as the starting material, and quicklime is obtained by calcining the limestone. The quicklime is then digested to produce a calcium hydroxide slurry, which is precipitated and converted into calcium carbonate crystals in the presence of carbon dioxide. Finally, precipitated calcium carbonate (PCC) products are made through filtration, washing, drying, and other processes. Due to its fine particle size and large surface area, it is suitable for use in rubber, plastics, papermaking, building materials, inks, daily chemicals, and other fields.

9. Casting Sand:

Limestone with a suitable particle size range is selected for crushing and screening to meet the requirements for casting sand. Binders and other additives are added as needed and mixed thoroughly with the limestone sand. This type of molding sand performs better than quartz sand, improving the surface quality and finish of castings, while also reducing the risk of occupational silicosis.

10. Desulfurization Absorbent:

Limestone is crushed and ground into fine powder to effectively capture SO₂ gas during the desulfurization process. The limestone powder is mixed with water and stirred into a slurry for use in wet flue gas desulfurization systems. In these systems, the powdered limestone reacts chemically with sulfur dioxide in the flue gas to achieve desulfurization.

11. Active Lime and Passivated Lime

Active lime is a high-quality metallurgical additive, while passivated lime has excellent moisture absorption and injection performance. Both are primarily used in the steel industry as sintering ore additives, slag-making agents, and desulfurization and dephosphorization agents in molten iron pretreatment.

12. Pharmaceutical Grade Calcium Carbonate:

Edible and pharmaceutical-grade calcium carbonate that meets strict standards is used as a nutrient additive in calcium supplement tablets and multivitamin tablets, as well as a fortifier in the food industry.

13. Edible Calcium Carbonate:

High-purity limestone that meets food safety standards is selected as the raw material, and a series of stringent quality control measures such as ultra-fine grinding, purification, and disinfection are implemented to ensure the product’s safety and purity. It is widely used in the calcium supplement nutrition and health food industries, in products like dairy, beverages, and cakes, to increase calcium content and improve taste.

The list above outlines the main types of products derived from limestone ore processing. Each product plays an indispensable role in its respective application fields due to its unique properties and functions. With advancements in science and technology, the deep processing of limestone continues to evolve, making its derivatives more diversified and meeting the growing demands of the market.

To improve the value and quality of limestone, it is pre-sorted using mineral processing equipment to remove impurities. This process helps enhance the purity and quality of the final product, thereby meeting a wider range of application needs.

Among the equipment used for this process are photoelectric mineral processing devices, such as ore color sorters and artificial intelligence (AI) sorters.

Color Sorter

The color sorter primarily detects the color differences in materials using optical sensors to distinguish between target substances and impurities. When limestone passes through the machine, the sensors identify particles that differ in color from pure limestone. These impurities are then blown out of the production line using compressed air or other means. This method is highly effective for removing impurities with significantly different colors.

AI Sorting Machine:

Compared to traditional color sorters, AI sorting machines employ more advanced technologies, including but not limited to machine vision and deep learning algorithms. These machines not only classify by color but also accurately identify and separate impurities based on multi-dimensional features, such as shape, texture, gloss, and other characteristics. After training, the AI system can detect small and complex differences, making it more effective at handling impurities that are similar in color to limestone but differ in composition.

Choosing the Right Equipment:

When selecting suitable equipment, mining companies must consider the following factors:

a. The type of impurities in the limestone raw material and their physical properties (such as color, shape, density, etc.).

b. The speed and processing volume requirements of the production line.

c. The investment budget and the technical maintenance capabilities of the equipment.

Additionally, depending on the actual conditions, it may be necessary to pre-treat the limestone (such as crushing and screening) to ensure the best sorting effect. Regular calibration and maintenance of the sorting equipment are also essential to ensure long-term stable operation and efficient performance.