Photoelectric color sorting is a method for the initial rough separation of quartz minerals and impurity minerals based on differences in their surface optical characteristics. It shows significant effectiveness in sorting coarse-grained minerals. Following the principle of discarding impurities as early as possible, quartz sand color sorting is typically arranged before grinding. It can preliminarily separate quartz ore into several grades for separate processing and utilization, enabling more rational development of quartz resources. This improves concentrate grade and beneficiation recovery rate while substantially reducing consumption.

1. The Principle of Quartz Sand Color Sorting

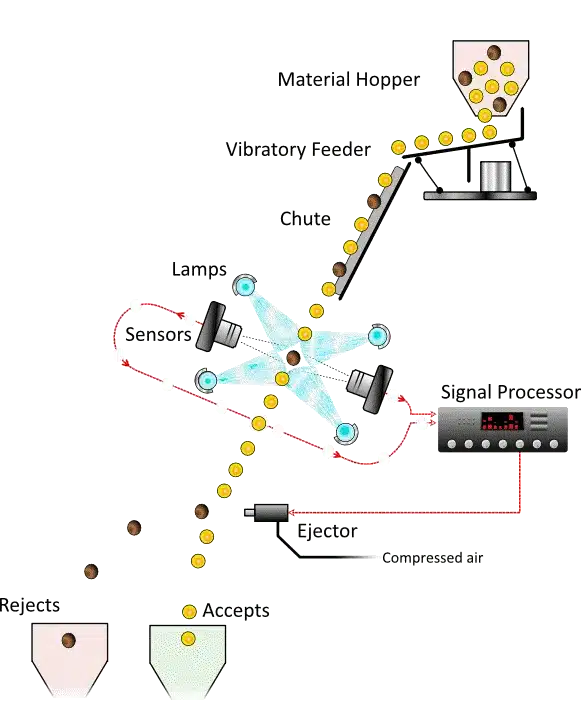

A color sorter is equipment that uses photoelectric detection technology to automatically separate heterochromatic particles from granular materials based on differences in their optical characteristics. It mainly consists of a feeding system, an optical detection system, a signal processing system, and a separation execution system.

In raw quartz sand ore, purer quartz sand appears white or milky white, while iron-bearing impurities or associated gangue minerals exhibit colors like light yellow, pale yellow, light brown, or grey. The color difference between quartz sand and these iron impurities or gangue minerals is the key basis for sorting.

2. Color Sorting Characteristics for Different Quartz Sand Size Fractions

The applicable range for quartz sand color sorting mainly focuses on sorting 3-8cm particles of raw ore, 0.5-3cm particles, and 4-140 mesh particles. The effectiveness of color sorting for different size fractions is influenced by various factors.

(1) Large-Grain Quartz Sand

Due to their larger size, these particles have a relatively larger contact area with the sorter. It makes it easier for the optical system to detect surface impurities and color differences. Furthermore, large grains are more stable during conveyance. They’re less prone to rolling or piling up, allowing for more accurate detection and separation. For example, in the production of quartz sand for construction, color sorting large grains effectively removes black, yellow, and other impurity particles, enhancing the purity and visual quality of the sand.

(2) Medium-Grain Quartz Sand

The sorting effect for medium-grain quartz sand is relatively balanced. It’s neither as easily detectable as large grains nor as challenging as fine grains. During sorting, the optical system and detection accuracy of the sorter must reach a certain level to distinguish impurity particles effectively. For instance, in industrial applications where extremely high purity is not critical, such as ordinary glass manufacturing, color sorting can remove most impurities with obvious color differences, meeting production needs.

(3) Fine-Grain Quartz Sand

Fine particles are prone to agglomeration or piling, which affects imaging and detection accuracy of the optical system. Their stability during conveyance is also poorer, easily influenced by air flow or vibration, leading to reduced sorting accuracy. However, with advancing color sorting technology, some advanced sorters, through optimized optics, higher detection precision, and special conveyance methods, can effectively sort fine grains. For example, in producing electronic-grade quartz sand, fine grains undergo precise color sorting to remove trace impurities, though multiple passes might be required for thorough cleaning. Achieving the required fineness for effective sorting often relies on efficient pulverization to ensure a consistent and well-liberated feed for the color sorter.

(4) Uniformly Sized Quartz Sand

If the particle size distribution is relatively uniform—meaning a stable proportion of different sizes—then controlling the sorter’s throughput and accuracy becomes easier. A uniform distribution enhances stability during conveyance and detection, reducing errors and difficulties caused by size variations. For example, in large-scale quartz sand production lines, pre-processing like screening to separate sand into different size fractions before sorting each fraction individually improves overall sorting efficiency and effectiveness. Preparing this uniformly sized feed typically involves controlled crushing and pulverization stages.

(5) Non-uniformly Sized Quartz Sand

When the size distribution is uneven, mixing large and small particles can occur. Large particles may block small ones from detection, and small particles might adhere to large ones, causing misjudgment by the sorter. Furthermore, an uneven distribution can lead to unstable throughput, affecting production efficiency and sorting results. For instance, in small quartz processing plants with limited equipment and technology, size distribution is often uneven, necessitating adequate screening and pre-processing before sorting to improve performance. In such casos, additional pulverization and clasificación steps may be needed to create a more homogeneous feed for the color sorter, mitigating these issues.

3. Key Performance Indicators for Color Sorters

(1) Throughput

Throughput refers to the amount of material processed per hour. Factors affecting throughput mainly include the servo system’s speed, the maximum belt speed, and the raw material’s purity. Faster servo movement allows quicker positioning of actuators to eject impurities, enabling higher belt speeds and increased throughput, and vice versa. Throughput is directly proportional to belt speed; faster belts mean higher output. It also relates to the impurity concentration; fewer impurities with larger gaps between them allow more reaction time for the servo system, permitting increased belt speed. Simultaneously, throughput is closely tied to the required sorting accuracy.

(2) Sorting Accuracy

Sorting accuracy is the percentage of ejected impurities relative to the total impurities in the feed. Accuracy is primarily influenced by belt speed and raw material purity. Slower belt speeds provide longer intervals between impurities, giving the servo system sufficient time to eject them, thus improving accuracy. Similarly, higher initial purity (fewer impurities) leads to higher sorting accuracy. Accuracy is also limited by the servo system’s design; if two or more impurities appear in the same image frame, only one can be ejected, reducing accuracy. A re-selection structure performs better than a single-selection one.

(3) Yield-to-Waste Ratio

This ratio refers to the amount of good product mistakenly ejected with the waste material. The ratio is adjustable, primarily by tuning the actuator activation time. If set too high, it affects the recovery rate and throughput; if set too low, the waste contains too much good material, causing losses. Re-processing this waste requires additional manpower and resources, leading to complications and economic loss. In practice, throughput, accuracy, and yield-to-waste ratio are interconnected key performance indicators and must be evaluated together.

4. Technical Key Points for Quartz Sand Color Sorting

(1) Factors Influencing Sorting Effectiveness

Camera resolution, software algorithms, the feeding system, and nozzle performance are crucial factors affecting sorting results. Of course, there are also comprehensive factors: when software upgrades and valve response speeds are sufficient, the servo system speed, maximum belt speed, and raw material purity then influence accuracy and throughput. Additionally, some manufacturers recirculate rejected material during sorting, significantly reducing final product yield, lowering the efficiency of obtaining qualified product within effective time, and increasing the yield-to-waste ratio. If the yield-to-waste ratio is set too high, it impacts the recovery rate and throughput; if set too low, the waste contains excessive good material, resulting in waste. The efficiency of the initial pulverization process directly impacts the liberation of impurities and thus affects these key sorting performance indicators.

(2) Debugging Techniques

Generally, increasing sensitivity improves sorting effectiveness but also increases the yield-to-waste ratio. Production throughput requirements also directly affect sorting results and the yield-to-waste ratio. The sorter’s belt speed is another important parameter. Some manufacturers, unable to optimize belt speed, increase material coverage on the belt. In production, this high coverage severely reduces the effective distance between particles, lowering resolution during sorting and allowing many bad particles to escape. Consequently, this approach only increases the yield-to-waste ratio and further reduces the net sorting recovery rate. Long-term, this fails to meet production requirements for mining companies, let alone recover costs or increase benefits.

If expected results aren’t met, besides improper debugging, another factor is the impurity level of the raw material. With low impurity concentration, the interval between impurities is larger, allowing more reaction time for the servo system, enabling higher belt speeds and increased throughput. Similarly, higher initial purity (fewer impurities) leads to higher sorting accuracy, which in turn allows for higher throughput. Furthermore, there must be a certain color difference between good and defective particles. Smaller color difference increases sorting difficulty, worsens performance metrics, and affects the rejection rate for particles of different colors. Optimizing the upstream pulverization can sometimes help by creating cleaner particle surfaces and enhancing this crucial color difference.

(3) Controlling Sorting Accuracy

The most critical factor affecting quality is sorting accuracy. Applications demanding high-quality products require high sorting precision. Taking quartz sand as an example, if producing sand for engineered stone slabs, high purity is essential—the quartz sand must have no yellow staining on the surface, and the stone hardness must be suitable—to meet industry standards for quartz slabs. Requirements are even stricter for high-purity quartz sand. Conversely, for quartz sand used as filler in ordinary glass, coatings, rubber, or plastics, quality requirements are relatively lower. Some impurity content might be acceptable, allowing a focus on throughput. The target product size for these different applications is precisely defined during the pulverization stage, which directly influences the subsequent sorting strategy and efficiency.

Polvo épico

Mastering quartz sand color sorting involves understanding its principles, the characteristics of different size fractions, and the intricate balance between sorter throughput, accuracy, and yield-to-waste ratio. From processing large grains to challenging fine powders, effective liberation and preparation of the material are foundational.

Maquinaria de pólvora épica specializes in providing robust and precise grinding and pulverization solutions that serve as the critical first step in mineral processing workflows. Contact us to have your tailored-made powder solution today.