In the realm of material processing, the three-roll modifers stands out as an essential piece of equipment across a variety of industries. Its unique mechanical design and exceptional processing capabilities make it indispensable for tasks requiring ultra-fine dispersion and material performance enhancement. Thanks to precise control over roller gaps, speed, and temperature, three-roll modifiers (also called three-roller coating machines) consistently deliver uniform, high-quality results that elevate the properties of processed materials.

The Core Structure of the Three-Roll Modifier

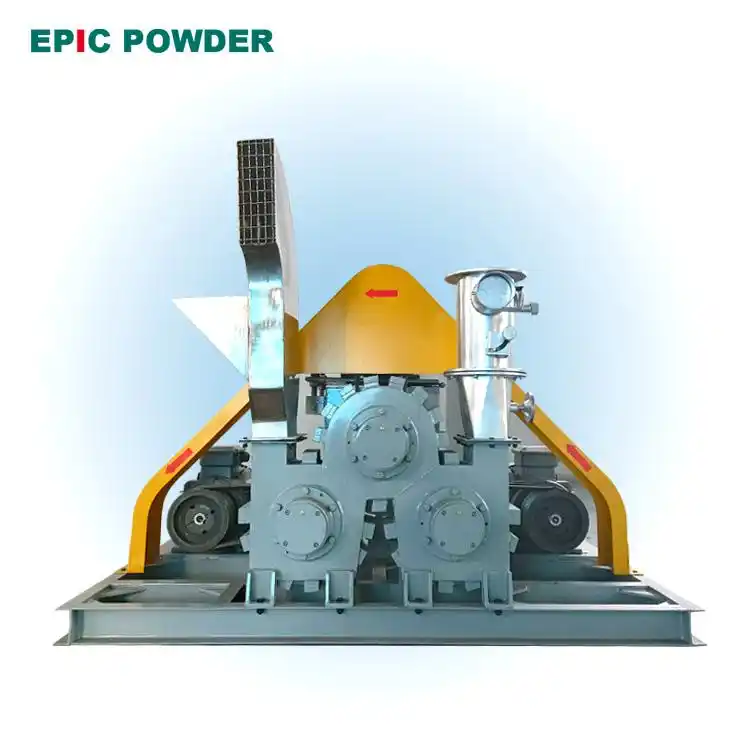

At the heart of the three-roll modifier is its distinctive tri-roller assembly. The three rollers — meticulously engineered and arranged either horizontally or vertically — work in tandem to impart shear, compression, and friction forces on the material. Each roller typically measures from hard-wearing alloy steel and undergoes specialized surface treatments, such as chrome plating or nitriding, to ensure durability, dimensional accuracy, and long-term stability.

What distinguishes these rollers is their precision gap arrangement. By finely adjusting the distance between the rollers, operators can tailor the intensity of shear forces and, consequently, the extent of dispersion or homogenization achieved. Additionally, the rollers rotate at varied speeds, creating a complex velocity gradient that generates multiple shear zones as the material flows through.

Working Principle of the Three-Roll Modifier

The operation of a three-roll modifier centers around precise mechanical synergy. Materials fed into the system pass through the successive roller gaps, experiencing repeated shearing, compressive, and frictional forces. This careful orchestration breaks up agglomerates, disperses fillers or additives evenly, and refines particle size distribution.

Moreover, a sophisticated temperature control system is integrated to maintain an optimal thermal environment. This is crucial because heat generated from shear can affect material properties, especially for heat-sensitive compounds or polymer matrices. Maintaining precise temperature conditions ensures product consistency and prevents degradation or unwanted chemical reactions during processing.

Key Industrial Applications of Three-Roll Modifiers

The adaptability and precision of three-roll modifiers have made them core to numerous industrial sectors. Traditionally, they have been widely adopted in the coatings and inks industry, where achieving ultra-fine and uniform dispersion of pigments and fillers directly correlates with enhanced color vibrancy, stability, and durability of products.

In the polymer materials sector, three-roll modifiers excel at uniformly blending additives, plasticizers, and fillers into polymer matrices. This improves mechanical properties, thermal stability, and enhances the end-use performance of plastics and composites.

Electronic materials manufacturing also benefits significantly. The equipment allows precision processing of functional powders and composites, optimizing electrical, magnetic, or optical properties required in components like conductive inks, display materials, and capacitors.

The continuous evolution of industry demands spurs new applications. In the burgeoning field of new energy materials, three-roll modifiers are increasingly used in the fine processing of electrode materials, such as lithium-ion battery cathodes and anodes. The precise dispersion improves ion transport and electrode stability, which directly impacts battery efficiency and lifespan.

Biomedical materials production likewise sees advantages, particularly in fabricating composite biomaterials with tailored microstructures. The equipment supports the homogenization and modification of materials used in implants, drug delivery systems, and tissue engineering scaffolds, where material uniformity is crucial.

Technological Innovations Driving Performance

Recent innovations have significantly enhanced the capabilities of three-roll modifiers. Integration of intelligent control systems allows for precise, programmable adjustment of roller speeds, gap distances, and temperature settings. This automation reduces operator error and ensures consistent product quality even during prolonged runs.

Real-time monitoring technologies, including sensors and feedback controls, permit continuous observation of process variables. By detecting deviations instantly, these systems enable proactive adjustments, minimizing downtime and variability.

Material science advancements have also contributed to equipment longevity and reliability. Novel wear-resistant coatings and composites for rollers and bearing components extend service life and maintain dimensional stability. This reduces maintenance frequency and avoids contamination risks arising from component wear.

Furthermore, energy-efficient designs and optimized motor controls have been engineered to reduce power consumption while enhancing milling throughput, responding to the growing emphasis on sustainable manufacturing.

What EPIC Powder’s Three-Roll Modifiers Deliver

At Qingdao EPIC Powder Machinery Co., Ltd., our three-roll modifiers embody the forefront of design and technological innovation in precision material processing. We engineer each system with high-performance rollers coated in premium wear-resistant materials to assure exceptional durability and contamination-free operation.

Our equipment includes advanced temperature regulation and programmable logic controllers, enabling precise, repeatable control over critical processing parameters. Customers benefit from consistent product quality, higher yields, and reduced downtime.

With extensive expertise across coatings, polymers, electronics, new energy, and biomedical sectors, EPIC Powder tailors solutions to match diverse processing challenges. Our commitment to research and customer collaboration ensures our three-roll modifiers continuously adapt to emerging material technologies and industrial needs.

Clients leveraging EPIC Powder modifiers have achieved significant gains in product consistency, processing efficiency, and downstream performance — essential competitive advantages in today’s fast-evolving markets.

Conclusion

The three-roll modifier remains a cornerstone in modern material processing industries owing to its precision, efficiency, and versatility.

Technological advances continue to expand the horizons of what three-roll coating machines can achieve, improving automation, reliability, and scalability. Qingdao EPIC Powder Machinery Co., Ltd. stands ready as your trusted partner, empowers your material processing and industrial success.

For more information about our three-roll modifiers or to discuss customized solutions tailored to your production goals, please contact the EPIC Powder team today. Together, we can elevate your manufacturing capabilities with precision and innovation.