In recent years, power battery technology has been advancing toward low cost, high safety, and superior cost-effectiveness. Lithium Manganese Iron Phosphate (LMFP) has gained significant attention for its high energy density and exceptional safety performance. However, challenges such as low electrical conductivity, suboptimal cycle performance, and the “voltage drop” issue caused by its dual voltage platform have limited its widespread adoption. In contrast, ternary materials (NCM) offer high specific capacity and energy density. However, it also faces drawbacks like poor thermal stability and high raw material costs. At Epic Powder Machinery, our jet mills are engineered to deliver ultra-fine grinding solutions tailored for battery cathode materials.

By physically blending or compositing LMFP with ternary materials, the strengths of both can be leveraged to offset their respective weaknesses. This composite system enhances energy density, improves low-temperature performance, reduces costs, and boosts safety, positioning it as a leading candidate for next-generation power batteries. Achieving optimal particle size distribution and uniformity in these composites is crucial for maximizing electrochemical performance. Advanced grinding technologies like jet mills play a pivotal role in precursor material preparation.

The Role of Jet Mills in LMFP and Ternary Material Processing

Epic Powder’s fluidized bed opposed jet mills, for instance, utilize high-velocity air jets to micronize materials through particle-on-particle collisions, achieving particle sizes as fine as 95% < 5 μm with minimal heat generation and contamination—ideal for heat-sensitive LMFP precursors. This technology ensures the high purity and narrow size distribution required for enhanced conductivity and ion diffusion in LMFP, addressing its inherent limitations.

Similarly, our spiral jet mills excel in processing ternary materials like NCM, where precise control over particle morphology prevents agglomeration and supports high-nickel formulations. By accelerating materials with supersonic air streams, these mills produce steep particle size distributions that improve packing density and energy output in composite cathodes. With over 20 years of expertise, Epic Powder’s jet mills offer energy-efficient operation, customizable air pressure for fine-tuned velocity, and easy-clean designs compliant with pharmaceutical-grade standards, making them indispensable for scaling up LMFP/ternary blends in industrial production.

Characteristics of Lithium Manganese Iron Phosphate (LMFP)

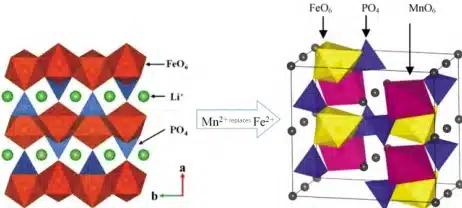

LMFP features an olivine-type structure, similar to LiFePO4, composed of LiO6, Mn(Fe)O6 octahedra, and PO4 tetrahedra. This structure provides excellent thermodynamic stability and safety. Compared to lithium iron phosphate (LFP), LMFP offers a higher voltage platform (4.1V for Mn2+/Mn3+ and 3.4V for Fe2+/Fe3+), resulting in a 10%-20% increase in energy density. However, its drawbacks include poor electrical conductivity and low ion diffusion rates, leading to higher internal resistance and reduced electrochemical performance. Jet milling at Epic Powder helps overcome these by refining precursor particles to sub-micron levels, boosting overall battery efficiency.

Characteristics of Ternary Materials (NCM)

Ternary materials possess an α-NaFeO2 hexagonal layered structure, delivering high specific capacity (170-210 mAh/g) and energy density. NCM622 LiNi0.6Co0.2Mn0.2O2) strikes a good balance between energy density and stability. However, high-nickel materials (Ni content ≥0.6) or those used at high voltages (≥4.4V) exhibit reduced safety and higher costs. Our air classifier mills at Epic Powder integrate grinding and classification in a single unit, enabling high-volume processing of abrasive NCM materials while maintaining uniform micron sizes essential for thermal stability.

Synergistic Benefits of LMFP and Ternary Material Composites

The combination of LMFP and ternary materials creates significant synergistic effects. LMFP’s thermal stability mitigates the thermal runaway risks of ternary materials, while the high capacity of ternary materials compensates for LMFP’s capacity limitations. Additionally, the discharge curve of ternary materials smooths out LMFP’s “voltage drop” issue. Incorporating LMFP also reduces overall material costs.

Research indicates that a 30%-40% LMFP blending ratio in ternary systems achieves an optimal balance of energy density, cycle life, safety, and cost. This offers high safety, high volumetric energy density, and cost-effectiveness. Epic Powder’s integrated jet mill and classifier production lines ensure seamless blending by providing consistent particle uniformity. It is key to unlocking these synergies at scale.

Industrial Progress

The LMFP/ternary composite system is demonstrating strong potential across various applications. In the power battery sector, CATL’s M3P battery, which utilizes this technology, has reached mass production and vehicle integration, validating its feasibility. The composite system is also gaining traction in high-end consumer electronics, power tools, and other applications. They require high volumetric energy density and rate performance.

As LMFP precursor processes mature and production scales up, costs are expected to decrease further. It accelerates the commercialization of LMFP/ternary composite technology across diverse scenarios. Epic Powder is at the forefront, supplying robust jet pulverization equipment that supports this growth with reliable, high-throughput solutions.

Epic Powder Machinery

As pioneers in ultra-fine powder processing, Epic Powder Machinery is committed to driving the future of advanced battery materials. Our comprehensive range of jet mill production lines empower clients to achieve breakthrough performance in LMFP/ternary composites. Epic Powder’s expertise ensures your materials are “Finer Material for a Better World.” Contact us today at www.epic-powder.com to explore how our jet milling solutions can supercharge your next-generation battery innovations.