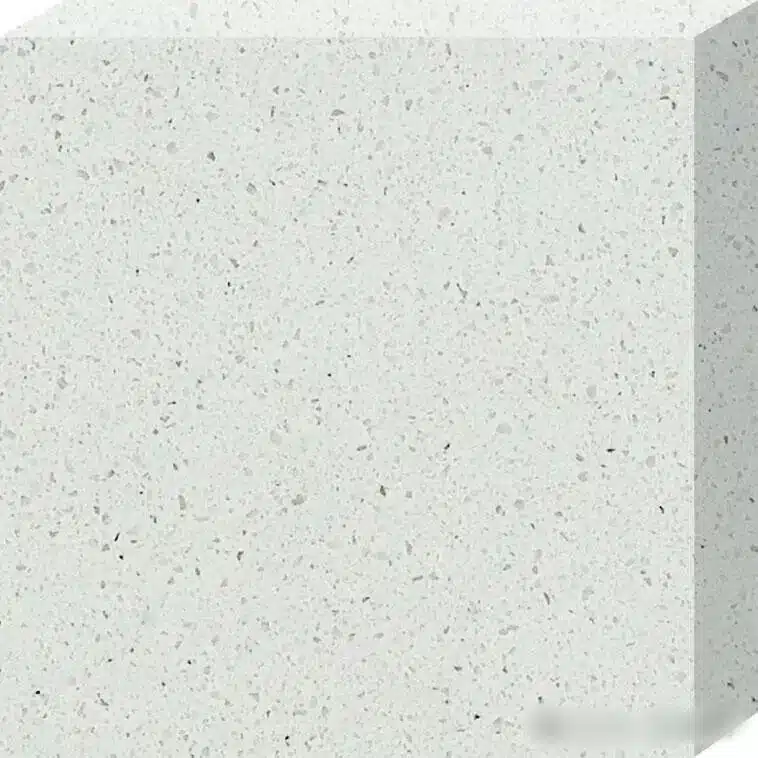

In the field of modern architectural decoration, engineered stone has become an indispensable material. It effectively serves as a substitute for natural stone, high-end ceramics, wood, and metal decorative materials. It’s also falling within the scope of green and eco-friendly building materials. Among these, engineered quartz stone is a key category of engineered stone, benefiting from quartz. Quartz is a mineral resource known for its highly stable physical and chemical properties. Engineered quartz stone is a rapidly developing representative within the engineered stone sector. It is primarily composed of 93% to 95% quartz and about 7% unsaturated polyester resin binder, along with pigments, curing initiators and other additives. After curing, it exhibits a hard texture, dense structure and vibrant colors. It has characteristics such as wear resistance, pressure resistance, high-temperature resistance, corrosion resistance, and anti-permeability. This makes it widely popular in the market. As a composite material, the quality of engineered quartz stone can be further enhanced and costs reduced through the use of modified quartz powder and advanced coating modification technologies.

High-Performance Modified Quartz Powder: An Excellent Assistant for Engineered Quartz Slabs

Engineered quartz stone is produced from quartz sand and quartz powder combined with resin, pigments, coupling agents, curing agents, etc., through high-temperature curing. Non-modified quartz powder is produced via a combined production line involving ball mills and classifiers. In contrast, modified quartz powder undergoes a secondary coating modification process in specialized modification machinery. The specific coupling agents for engineered quartz stone are added to the non-modified powder.

Due to the significant difference in properties between the inorganic interface of non-modified quartz powder and the organic interface of the resin, the bonding force is weak. However, after the modification process, the surface of the quartz powder is covered with a coupling agent. This agent acts like a bridge, connecting the quartz powder and the binder. It significantly enhances the adhesion between the adhesive and the powder. Tests show slabs with modified quartz powder have higher strength. They also have better glossiness. While wear and water absorption are slightly higher, the overall performance is superior.

Epic Powder Modification Equipment: Advantages and Features

The coating modification process is crucial for enhancing the performance of quartz powder. Epic Powder modification machines excel in this area, offering several distinct advantages and features for quartz powder coating modification:

High-Efficiency Modification: Epic Powder equipment ensures uniform and complete coating of each quartz powder particle. This significantly improves modification efficiency and consistency.

Intelligent Control System: Advanced automated control systems allow for precise adjustment of modification parameters, ensuring stable and high-quality modification results.

Energy Saving and Environmental Protection: The design focuses on low energy consumption and minimal dust emission, aligning with green production standards.

Strong Adaptability: Suitable for the coating modification of various powder materials, including quartz powder, meeting diverse production needs.

Modified Quartz Powder Helps Engineered Quartz Stone Reduce Costs, Increase Efficiency, and Enhance Competitiveness

The main raw materials for organic engineered quartz stone include unsaturated polyester resin, quartz powder, and quartz sand. Auxiliary materials include pigments, curing agents, coupling agents, etc. Among these, unsaturated polyester resin accounts for approximately 8%-15% of the formula mass ratio. The raw materials for organic artificial granite are basically the same as those for quartz stone, with the only difference being that the sand/powder raw material is calcium carbonate-based. However, the unsaturated polyester resin content in artificial granite is about 5%-11% of the formula mass ratio, indicating a significant difference in resin usage.

The Root Cause: Interfacial Compatibility Between Powder and Resin

Industry research reveals that the performance difference stems from the fact that most quartz powder used in the former lacks surface modification treatment. This leads to poor interfacial compatibility between the resin and the powder, and consequently higher resin usage. In contrast, the calcium carbonate powder widely used in artificial granite undergoes mature modification treatment, resulting in good resin-powder compatibility and lower resin consumption. Analysis of quartz slab material costs shows that reducing resin usage has the most significant impact on lowering overall costs.

The quartz powder used in organic engineered quartz stone is primarily produced through mature ball milling technology. However, as an inorganic polar material, quartz powder has a surface rich in active silicon hydroxyl groups and trace adsorbed water, making it difficult to fully wet and disperse when mixed with the non-polar unsaturated polyester resin. To meet the fluidity requirements of the production process, resin dosage often needs to be increased. After coating modification, the interfacial compatibility between quartz powder and resin is significantly improved, slurry fluidity is greatly enhanced, and the required resin amount is noticeably reduced. Simultaneously, the oil absorption value of the modified quartz powder decreases, further optimizing the formulation.

Excessive resin weakens the product and raises costs. Now, China’s real estate economy is slowing down. This has intensified competition in the quartz stone market. It makes product cost-effectiveness key to enterprise survival. Quartz powder surface modification technology can not only increase the mass proportion of filler in the formula, enhancing deformation resistance, but also effectively reduce production costs.

Does Modified Quartz Powder Affect Color Difference in Quartz Slabs?

Among the raw materials, quartz powder and its usage quantity have the most significant impact on resin consumption. The amount of powder used is often determined by the customer’s required appearance and color pattern. The quartz powder surface contains lots of silicon-oxygen bonds and hydroxyl groups, it is highly polar and prone to agglomeration. Meanwhile, the unsaturated resin used for quartz stone belongs to the category of organic polymer materials, exhibiting poor compatibility with the highly polar inorganic quartz powder. To improve the dispersion of quartz powder and its compatibility with organic polymer materials, surface modification treatment is typically applied. The appearance and color quality of quartz slabs are among the most important indicators of their physical and chemical properties. Does modifying quartz powder affect the product’s appearance and color?

After coating modification, where the quartz powder surface is coated with a modifier, its optical properties such as refraction and scattering change, leading to a decrease in blue-light whiteness by approximately 1 degree. Experiments show that when the raw quartz powder has higher initial whiteness, the decrease in whiteness after modification is smaller. Conversely, when the raw material whiteness is poorer, the decrease is greater. After modification, the modifier coats or grafts onto the quartz powder surface. They form a coating layer that reduces the surface refractive index of the powder, thereby lowering its whiteness. During the polishing of engineered stone, the surface reveals quartz particle cross-sections. Most of the modifier coating on the powder is removed. Thus, although the powder’s own whiteness decreases, the final slabs show almost no color difference. The impact of quartz powder modification on hue is not significant and is almost imperceptible in practical applications.

Эпический порошок

In summary, adopting modified quartz powder is a crucial strategy for enhancing the performance and reducing the costs of engineered quartz slabs. The Epic Powder modification machines, ensures superior modification results, leading to improved product quality, reduced resin usage, and lower production costs. This approach significantly strengthens the market competitiveness of quartz slab products. For manufacturers aiming to optimize costs and enhance their competitive edge, investing in quartz powder surface modification technology is a highly recommended solution. Contact us for your tailorder-made solution today.