The rise of 3D printing, especially selective laser melting (SLM) and direct metal laser sintering (DMLS), has changed how designers and manufacturers think about jewelry production. Advanced powder technologies are enabling new possibilities for intricate forms, custom designs, and tailored properties in rings, earrings, pendants, and watches. At the heart of this revolution lies the need for high-quality, ultrafine metal jewelry powders with specific size distributions and purity levels. Qingdao EPIC Powder Machinery Co., Ltd. specializes in jet mill solutions engineered for these demanding processes. This article explores common powders used in jewelry, explains the unique value of jet milling technology, addresses key operational considerations, and provides data-backed insight into how jet milling from EPIC Powder raises quality and production standards for metal 3D printing.

Common Powders in Jewelry: From Titanium to Noble Metals

Jewelry applications demand a remarkable spectrum of metallic, functional, and decorative powders. Titanium alloys rank among the most popular due to their outstanding strength-to-weight ratio, hypoallergenic properties, and modern aesthetic appeal. Their use in 3D-printed rings and earrings is rapidly growing, especially in bespoke or lightweight components.

Noble metal powders dominate traditional fine jewelry. 18K gold — an alloy of gold with copper and silver — remains a standard for high-value custom pieces. Platinum powders, known for their chemical inertness and brilliant finish, are increasingly chosen for premium or limited-edition jewelry. Both require exceptionally pure, spheroidized, and finely divided powders to ensure successful layer-by-layer construction in metal additive manufacturing.

Innovative functional and specialty powders are also making their mark. Nanosilver, famed for its antimicrobial properties, is now used in coatings for earrings and piercings to reduce infection risks. Rare-earth phosphor powders, capable of emitting light, allow designers to create glow-in-the-dark pendants and customized night-jewelry. Ultrafine, well-dispersed powders are essential to achieve the desired effects in both appearance and performance.

Market data illustrates this growth. By 2024, the global 3D-printed jewelry market is projected to exceed $1.35 billion, with metal powder consumption reaching over 250 metric tons annually for direct metal 3D printing alone. The ultrafine powder segment is expected to see annual growth rates above 25%, driven by precision applications and new design trends.

Why Use Jet Mill Technology for Jewelry Metal Powders?

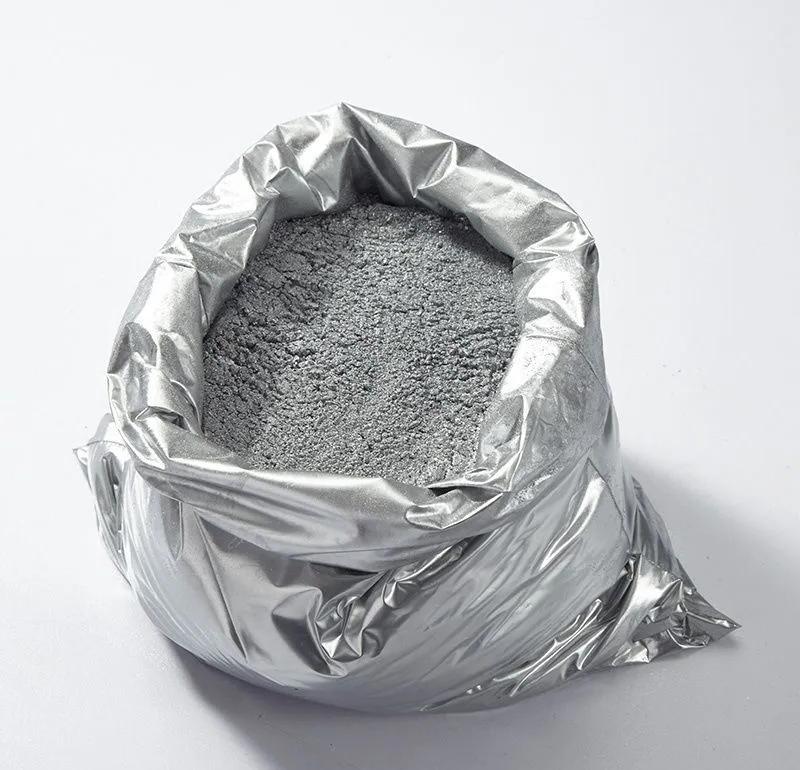

After atomization, metal powders may be too coarse or non-uniform for precision 3D printing. Jet milling is the proven solution for size refinement and quality enhancement of these powders.

The jet mill employs high-velocity air or inert gas to induce particle-on-particle collisions inside a closed chamber. This process rapidly reduces particle size while avoiding mechanical grinding contact. Because of this, powders are further refined to target ranges. They’re typically between 10 and 50 microns for jewelry SLM and DMLS applications. This strict control ensures that each successive powder layer during printing fuses evenly and contributes to a superior surface finish and microstructure.

In practical terms, jet milling allows jewelry manufacturers to produce intricate structures such as delicate filigree earrings, latticework rings, or hollow pendants featuring fine interior channels that would be impossible with casting or CNC alone.

Coating performance also benefits. Jet-milled nanosilver powders enable even antibacterial layers on earring surfaces without clumping, while ultrafine rare-earth phosphor particles distribute evenly in luminous coatings for night-glow pendants, improving visual quality and long-term wearability.

Cases demonstrate the power of this technology. One EPIC Powder customer, a European custom jewelry studio, reported a 40% improvement in print resolution and nearly eliminated failed builds after shifting from mechanically milled to jet-milled titanium and gold powders.

Issues to Consider When Jet Milling Metal Powders for Jewelry

While jet milling offers significant benefits, several technical and process factors require careful management, especially for precious or hard-to-handle materials.

Feedstock purity must be protected throughout the process. Even trace contamination can spoil the color or properties of noble metals like gold or platinum. This is why EPIC’s jet mills utilize ceramic or silicon carbide linings to maintain purity levels below 5 ppm metal contamination—a key benchmark for jewelry-grade powders.

Particle shape and morphology are also crucial. Spherical or nearly spherical powders flow and pack better during 3D printing, yielding more consistent layer density and mechanical performance. Producing and maintaining this morphology means controlling gas pressure, feed rate, and residence time in the jet mill.

Moisture sensitivity presents another challenge. Powders for jewelry must be processed and handled in low-humidity, temperature-stabilized environments. Both moisture and oxidation can degrade appearance or reactivity, especially for reactive metals and silver.

Operational safety is critical. Finely divided metal powders are combustible and may pose dust explosion risks. Advanced dust collection, inerting systems, and explosion mitigation measures are necessary to create a safe manufacturing environment.

Size uniformity is non-negotiable. Inline sieving and real-time particle size monitoring help maintain a consistent product between batches, which is essential for batch traceability in precious jewelry work.

Regular maintenance of wear parts—nozzles, liners, and classifier wheels—is vital to avoid product fluctuations or equipment downtime, especially given the abrasive nature of some functional powders.

Advantages and Disadvantages of Jet Mill for Jewelry Metal Powders

Jet milling offers several unique strengths that have established it as the industry standard in jewelry powder production.

First, the process delivers unparalleled purity and minimizes contamination—a significant benefit for high-purity precious metals. Second, jet mills provide tight particle size control. It allows jewelry producers to target the exact dimensions required for SLM, DMLS, or fine coating applications. Third, the cooling effect of gas expansion limits heat build-up, which protects oxidation-sensitive metals from color or structural changes.

Furthermore, jet mills can operate in inert atmospheres (using nitrogen or argon). This is essential for oxidizable or reactive metals and for preventing tarnish or color change in silver or rare earth powders. Continuous, closed-cycle designs support both pilot-scale experimentation and industrial-scale production with consistent results.

However, jet milling does have some limitations. The process is energy-intensive, especially when reducing already fine atomized powders to the sub-30-micron range. This can result in higher operational costs, especially for batch runs of expensive metals. Wear on nozzles and liners, particularly when processing hard or abrasive powders, necessitates investment in wear-resistant parts and scheduled downtime for maintenance. Some specialty powders require feedstock pre-screening or controlled feed rates to prevent process interruptions.

Finally, the initial equipment investment can be significant. Yet, for high-value jewelry and advanced design work, the return in yield, quality, and design flexibility often justifies the investment.

What Effects Can Be Achieved with the EPIC Powder Jet Mill for Jewelry Metal Powder?

EPIC Powder Machinery’s jet mill solutions are engineered for maximum performance, reliability, and adaptability across the jewelry sector.

Our mills allow precise adjustment of gas pressure, classifier speed, and feed rate. It enables the creation of consistent metal powders in the optimal 10-50 micron range for 3D printing.

By using advanced ceramic or silicon carbide linings, we minimize cross-contamination and extend component lifetimes, which is vital for batch-to-batch product consistency. Our closed-loop, inert-gas processes enable safe, oxidation-free processing of silver, platinum, and custom alloy powders.

Print defect rates for customized fine jewelry structures drop by 30% or more. In coatings, the use of jet-milled nanosilver achieves antibacterial performance with up to 40% higher efficacy and a more uniform surface appearance.

Our experience in application support—ranging from trial milling of new alloy blends to process optimization for rare earth phosphors—helps customers accelerate innovation and maintain competitive advantage.

About Epic Powder

The use of jet milling is transforming how fine metal powders are produced for jewelry 3D printing and coating. As demand for customized, intricate, and high-value jewelry grows, manufacturers must combine advanced design with uncompromising material quality. Jet mill technology, especially as engineered by Qingdao EPIC Powder Machinery, delivers the ultrafine, pure, and uniform powders needed for next-generation jewelry. From gold and platinum to titanium and functional nanomaterials, our innovative jet mills help unlock new creative possibilities while ensuring reliability and safety at each production stage.

For further information, technical consultations, or to discuss how EPIC Powder can support your jewelry powder needs, please contact our expert team. We look forward to helping you achieve outstanding results and grow your business with world-class ultrafine powder solutions.