Barium sulfate, also known as barite, is a colorless, odorless, and non-toxic inorganic compound with the chemical formula BaSO4. It features high density, high whiteness, good chemical stability, and resistance to acids and alkalis, and is insoluble in water and most acids. These properties make barium sulfate widely applicable in various fields.

Natural Barium Sulfate – Barite Powder

Barite is a white or gray powder with relatively coarse particles, typically ranging from 2 to 5μm. It is brittle with a pH of 4.5. After crushing and classification, it achieves a fineness of 250 mesh pass rate and a barium sulfate content exceeding 90%.

Synthetic Barium Sulfate – Precipitated Barium Sulfate

Precipitated barium sulfate is of higher purity and has a smaller particle size distribution: 4% at 1.5–2μm, 10% at 1.0–1.5μm, 46% at 0.5–1.0μm, 10% at 0.5μm, and 40% below 0.5μm. The pH of synthetic barium sulfate ranges from 6.6 to 8.0.

Wide Applications of Barium Sulfate in Plastics

(1) Filling and Modification

As a functional filler, barium sulfate can enhance the hardness, strength, and heat resistance of plastics. It is commonly used in modifying general-purpose plastics (such as PP and PVC) and engineering plastics (such as PA and PET) to improve their physical and processing properties. For example, adding barium sulfate can significantly increase the gloss and hardness of PP, giving its surface a resemblance to ABS, without affecting other properties of PP.

(2) Chemical Corrosion Resistance

Barium sulfate possesses good chemical inertness, which enhances the chemical corrosion resistance of plastic products. This makes it suitable for applications requiring durability, such as home appliance housings and automotive components.

(3) Improved Appearance

The high whiteness and gloss of barium sulfate help improve the appearance of plastic products, enhancing their visual appeal. For instance, adding barium sulfate functional masterbatch to BOPP film can increase the film’s gloss and whiteness, improving print results.

(4) Cost Reduction

Due to its relatively low cost, using barium sulfate as a filler can effectively reduce the production cost of plastic products. Typically, filling with barium sulfate can reduce the need for other expensive fillers (such as titanium dioxide), thereby lowering overall material costs.

(5) Enhanced Mechanical Properties

The incorporation of barium sulfate can improve the tensile strength and impact strength of plastics, performing particularly well in composite materials. For example, studies show that PA66 composites with activated barium sulfate exhibit significant improvements in both tensile strength and flexural strength.

Two Common Functional Masterbatches for Films

Based on these properties of barium sulfate, here are two common functional masterbatches for films: Pearl Masterbatch and Light Diffusion Masterbatch.

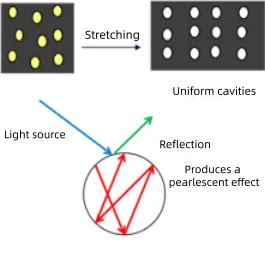

1. Pearl Masterbatch

Principle – Reflection: Pearlized films are generally produced using raw materials like polypropylene resin, mixed with calcium carbonate and pearlescent pigments, followed by biaxial orientation. During the actual production of pearlescent paper, fine calcium carbonate masterbatch particles are uniformly dispersed in the PP. After biaxial stretching, uniform micro-voids are formed. When light strikes the film, some light is reflected, while the rest undergoes multiple reflections within these voids, creating a pearlescent effect.

- Pearlescent Agents: Barium Sulfate, Calcium Carbonate, Silicon Dioxide.

- Application: BOPET pearlescent films are widely used in advertising, printing, labels, food packaging, and other industries.

- Product Example: MTA10289-A1 Pearl Masterbatch from Suzhou Polycore Materials Technology Co., Ltd. is a cost-effective product specifically customized for the BOPET industry. The resulting BOPET pearlescent film features a smooth surface free of gel particles, high opacity, pure white color, and an excellent pearlescent effect.

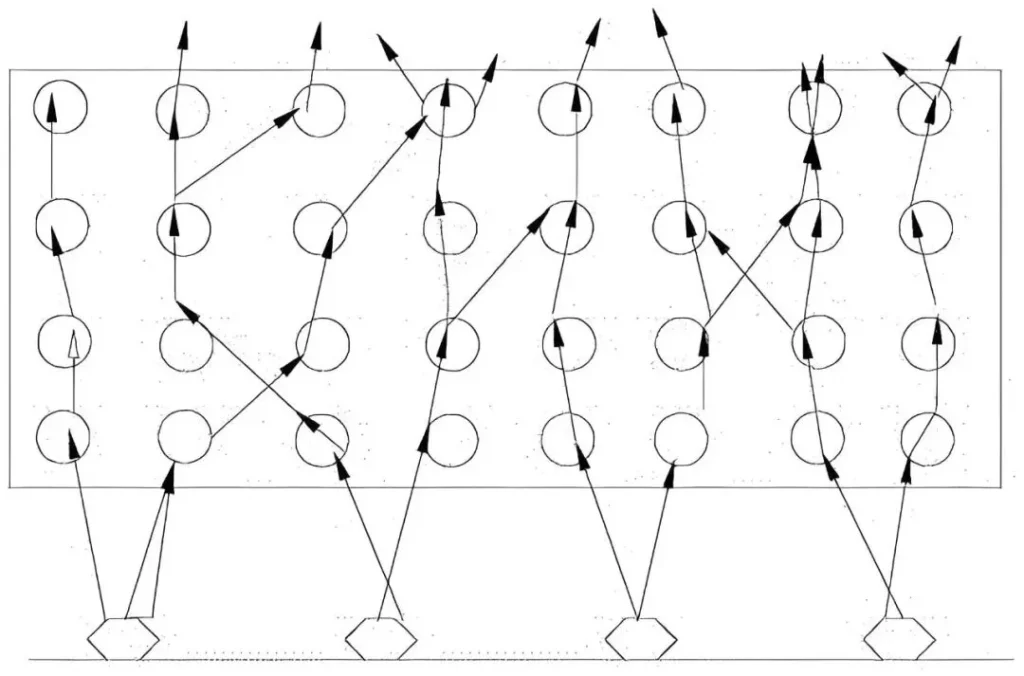

2. Light Diffusion Masterbatch

Principle – Refraction: Inorganic or organic light diffusing agents are added to a transparent matrix. Light undergoes countless refractions at the surfaces of these fine particles, achieving light diffusion and homogenization.

Inorganic Light Diffusing Agents: Barium Sulfate, Silicon Dioxide.

Organic Light Diffusing Agents: Styrenic type, Acrylic resin type, etc.

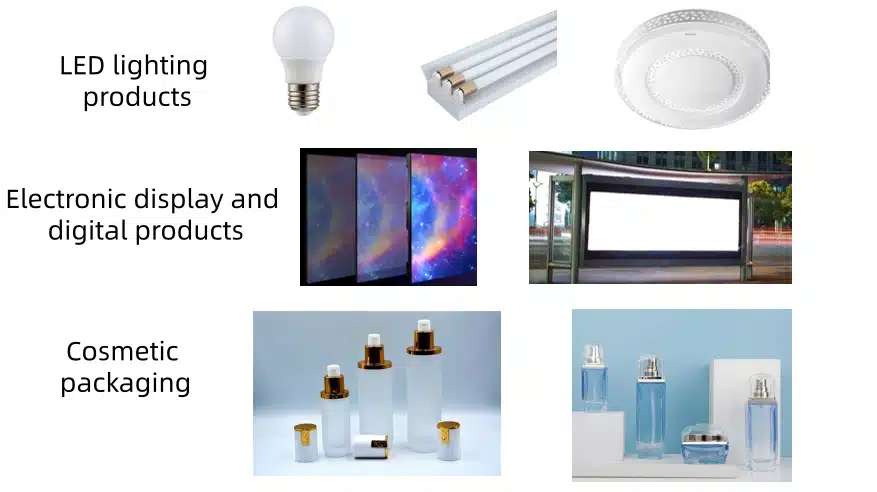

Application:

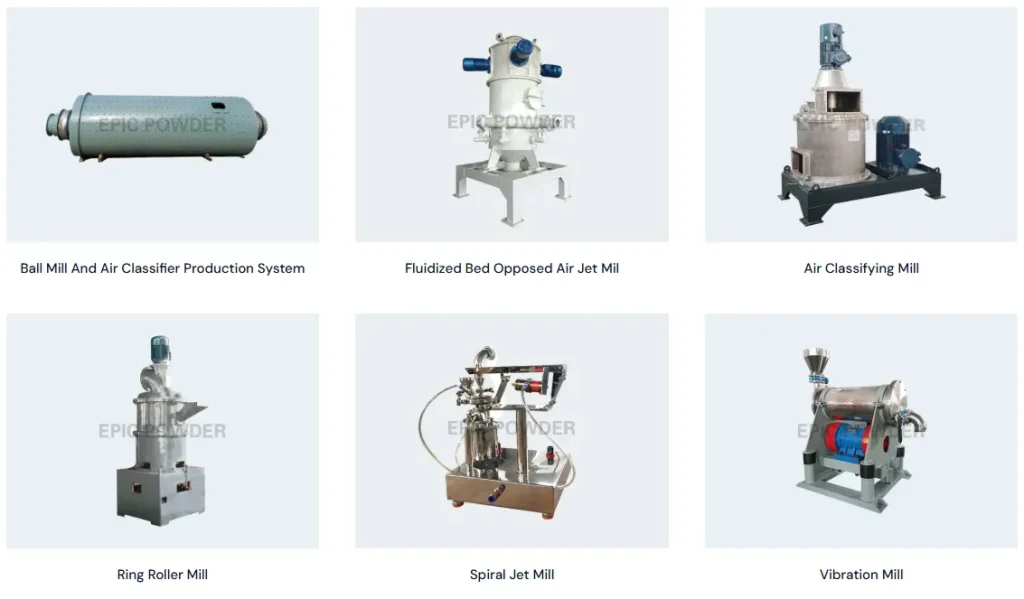

Epic Powder

To fully unlock these performance benefits in your masterbatch and film products, the foundation lies in high-quality, consistently fine barium sulfate powder. Epic Powder Machinery is your expert partner in precision particle size reduction. Our advanced jet milling and classification systems are engineered to produce the fine, uniform barium sulfate powders essential for achieving high gloss, excellent dispersion, and optimal light effects in demanding applications. By ensuring superior raw material quality, we help you create more marketable and high-performing plastic films.

Choose Epic Powder Machinery to drive your innovation forward.