See proven data! Epic Powder Machinery’s Clasificadores de aire deliver precise D97 & D50 control for calcium carbonate. Boost product value for plastics, paints & coatings. Request a free test report!

In today’s high-performance materials industry, ultra-fine non-metallic mineral powders have become indispensable. Ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), talc, kaolin, wollastonite, and quartz powders with particle sizes below 10 μm are widely used in premium coatings, plastics, paper, sealants, and advanced composites. Achieving narrow particle size distribution and high purity at commercial scale is the biggest challenge for producers.

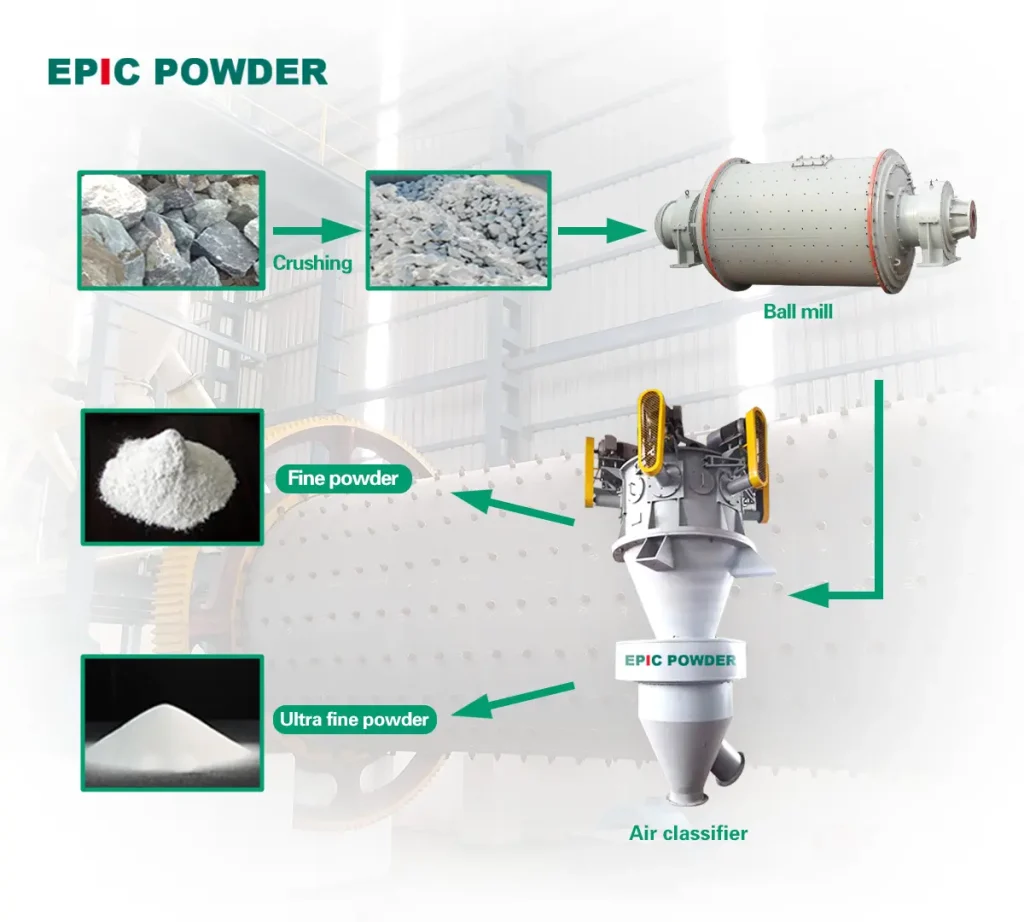

Traditional vibrating screens lose efficiency above 325 mesh (44 μm) and become completely impractical below 20 μm. This is where a modern clasificador de aire for non-metallic mineral powder becomes the only viable solution. Using precisely controlled centrifugal and drag forces, turbine air classifiers separate fine and coarse particles with micron-level accuracy while maintaining ton-per-hour throughput. Among the many options available, Epic Powder Machinery’s HTS series has earned a reputation for delivering some of the tightest cuts and highest capacities in real production environments.

What is an Air Classifier and How It Works in Non-Metallic Minerals

A forced-vortex turbine air classifier (also called turbo classifier) consists of a high-speed rotor with clasificación wheels surrounded by a secondary air system. Feed material enters the classification zone tangentially. Centrifugal force pushes larger particles outward to the coarse discharge, while drag force carries finer particles inward through the rotor into the fine powder outlet.

The latest horizontal multi-rotor designs used in the HTS series dramatically improve separation sharpness compared to single-rotor or vertical classifiers. Multiple classification stages in one body, combined with optimized dispersion and secondary air, allow D97 cuts as fine as 6–10 μm at industrial-scale throughput with virtually zero oversize contamination.

Why Non-Metallic Mineral Producers Choose Air Classifiers Over Other Methods

- Mechanical screens: limited to ≥325 mesh, blinding issues, low yield

- Gravity settling chambers: poor precision, huge footprint

- Single-rotor air classifiers: lower efficiency below 15 μm, capacity drops sharply

- HTS multi-rotor turbine classifiers: D97 6–10 μm at 1–2 t/h, steep PSD, energy-efficient

For high-end applications such as automotive coatings or high-gloss paper, even 1–2 μm difference in D97 can determine product acceptance. The HTS series consistently delivers repeatability within ±0.5 μm shift-to-shift.

How Air Classification Unlocks New Value in Calcium Carbonate

Air classification is not just about separation. It’s a value-creation process. By precisely controlling particle size, you can engineer your calcium carbonate for specific applications:

From Filler to Performance Additive: Precise classification transforms GCC from a simple volume-extending filler into a functional material that directly influences end-product properties like impact strength in plastics, opacity and sheen in paints, and bulk and brightness in paper.

Meeting Stringent Market Standards: Top-tier applications require tight control over the “top cut” (D97). Air classification is the most efficient method to ensure no oversized particles spoil a batch, guaranteeing consistent performance for your customers.

Optimizing Production Economics: By removing already-in-spec fine powder from the grinding circuit, you can increase overall mill efficiency. Furthermore, you can produce two saleable products—a fine fraction and a coarse fraction—maximizing the return from a single feed material.

How Our HTS Air Classifier Works

The Epic Powder HTS Air Classifier achieves this precision through an elegant and highly controlled mechanical principle.

The core of the system is a high-speed rotating classification turbine. The process begins with the feed material being evenly dispersed into an air stream. This mixture is then directed into the classification zone surrounding the turbine.

Here, two competing forces act on each particle:

Centrifugal Force: Generated by the high-speed turbine, this force pushes particles outward, away from the center.

Air Drag Force: The incoming airflow creates a drag force that pulls particles inward toward the turbine.

The separation happens in an instant:

Fine Product: Particles where the air drag force overcomes the centrifugal force are pulled through the gaps in the turbine blades and collected as the fine fraction.

Coarse Product: Particles that are too large or heavy (subject to greater centrifugal force) are thrown outward against the classifier wall, fall down, and are discharged separately.

The key to precise control? By simply adjusting the rotational speed of the turbine, we can accurately and repeatably change the cut point, allowing you to dial in the exact D97 specification you need.

Classification Data for Calcium Carbonate

Theoretical principles are best understood through practical results. Below is performance data from our HTS series Air Classifiers processing calcium carbonate, demonstrating their capability to deliver precise cuts at high throughputs.

Real Performance Data: Calcium Carbonate Classification Examples

| Feed Size | Fine Powder D97 | Coarse Powder D50 | Capacity (kg/h) | Modelo |

|---|---|---|---|---|

| Malla 325 | 9.51 μm | 15.10 μm | 800 | HTS315 |

| Malla 325 | 7.72 μm | 15.12 μm | 1500 | HTS400 |

| 500 mesh | 6.82 μm | 16.70 μm | 1600 | HTS500 |

| 600 mesh | 6.25 μm | 16.20 μm | 1650 | HTS500 |

| Malla 325 | 7.75 μm | 17.70 μm | 2000 | HTS100/4 |

This data highlights two key capabilities:

Exceptional Precision: Across various feed sizes and models, the HTS series consistently delivers tightly controlled D97 values for the fine product, which is critical for high-value applications.

High-Volume Processing: The equipment achieves this precision at industrial-scale throughputs, ensuring that quality and productivity go hand-in-hand.

The Value of Non-Metallic Mineral Powders

Non-metallic minerals, such as calcium carbonate (CaCO3), barite, talc, and silica, are very important to modern industry. They are not just inert fillers, but also functional additives that impart specific properties to a final product. The value of these properties, however, is almost entirely dependent on their particle size and distribution.

In Plastics & Rubber: A fine, controlled particle size in fillers like calcium carbonate improves impact strength, surface finish, and gloss. It also allows for higher loading levels, which reduces the consumption of expensive petroleum-based resins, directly lowering material costs.

In Coatings & Paint: Particle size dictates opacity, brightness, viscosity, and texture. An ultrafine powder provides a smooth, high-quality finish, while even a few oversized particles can ruin a batch.

In Construction & Adhesives: In products like concrete or sealants, particle size influences reactivity, flowability (rheology), and final strength.

The “ultrafine challenge” is where the highest value is found. The market for high-performance materials increasingly demands powders with a D97 of less than 10 microns (meaning 97% of the particles are smaller than 10μm). This level of precision is impossible to achieve accurately or economically with traditional sieving methods, which leads to inconsistent product quality and lost revenue.

Proven Results on Other Non-Metallic Minerals

The same HTS platform excels with talc (D97 8–12 μm at 2–4 t/h), wollastonite (needle-shaped preservation with D97 < 10 μm), kaolin, barite, mica, quartz, and graphite. Customers routinely achieve narrow distributions that meet the most demanding specifications in plastics, rubber, and high-performance coatings.

Why Epic Powder Machinery’s Air Classifier is Your Strategic Choice

Unmatched Classification Precision

Our classifiers are engineered for one primary goal: to deliver the sharpest possible cut. This ensures you can reliably meet the most demanding D97 and D50 specifications, batch after batch, building trust with your most discerning customers.

High Efficiency & Large Capacity

With optimized internal airflow dynamics, the HTS series achieves high classification efficiency even at maximum throughput. This means more of your input material is accurately separated into your target products, boosting your overall process yield and profitability.

Proven Reliability for Abrasive Materials

Calcium carbonate is abrasive. We build our classifiers to last, with options for wear-resistant linings, hardened components, and robust construction in critical areas. This design philosophy minimizes downtime and mantenimiento costs, maximizing your return on investment.

Expert-Led Application Support

We provide more than just a machine; we provide a solution. Our team offers deep expertise in calcium carbonate processing, helping you select the right model and configuration to meet your specific production goals and product portfolio.

Your Partner in Precision Classification

En Maquinaria de pólvora épica, we believe the best proof is in your own material. We invite you to put our technology to the test.

We offer a comprehensive free test classification service in our application lab. Send us a sample of your calcium carbonate, and our experts will process it and provide you with a detailed report on the achievable fineness, yield, and efficiency.

Ready to transform your calcium carbonate into high-value, specification-grade products?

Contact Epic Powder Machinery today to schedule your free test and receive a detailed performance report. Let us demonstrate how our HTS Air Classifier can become your most powerful tool for growth.

Polvo épico

In a competitive market, the ability to consistently produce calcium carbonate with a precise particle size distribution is a decisive advantage. Air classification is the key technology for achieving this, moving your products up the value chain. Partnering with Epic Powder Machinery gives you access to proven technology, reliable data, and the expert support needed to turn your calcium carbonate into a premium, high-performance product.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Posted by Jason Wang, Senior Engineer