Industrial Pulverizer & Grinding Machine Manufacturer for Dry Grinding

Types of dry grinding equipment

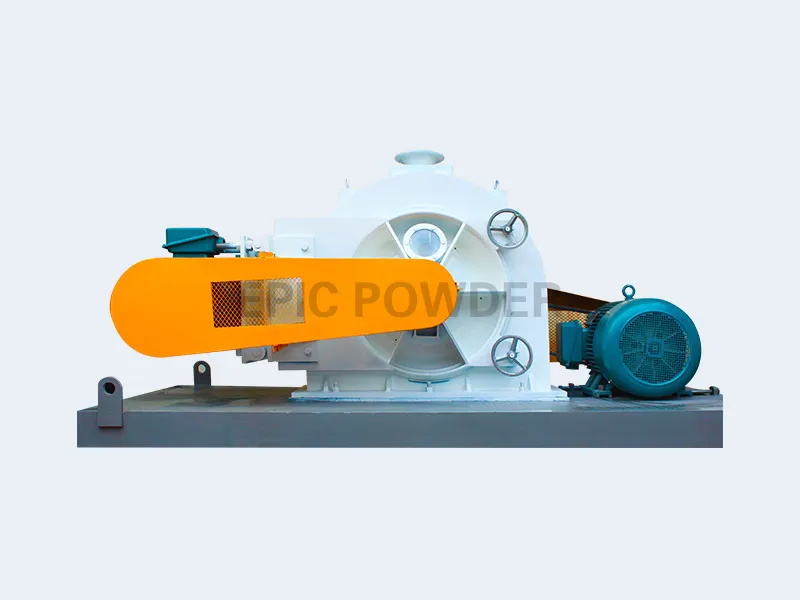

Impact mill

High efficiency, this pulverizer machine combines dual milling effects of impact and grinding for superior particle size reduction. It delivers a large milling ratio with a simple yet robust structure, ensuring stable operation ideal for continuous processing. This grinding machine is perfectly suited for pulverizing medium-soft to hard materials with consistent results.

Jet pulverizer

Uses the high speed turbulence airflow generated by compressed air or superheated steam as miling power. impactextrusion, friction and shear between the particles or between the particles and the fixed plate occur, so as to achievemilling.

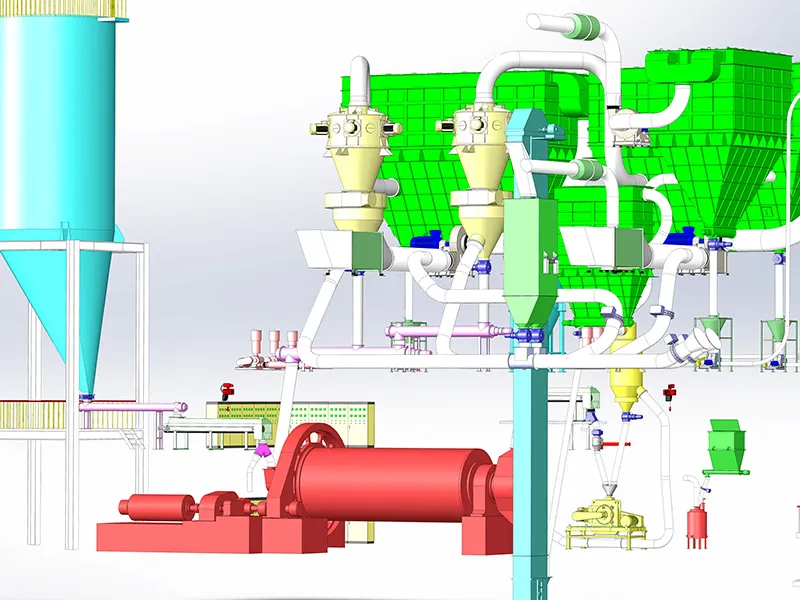

Ball mill + Classifier

The ball mill and classifier production line is a fully integrated grinding system designed for efficient processing of various mineral and industrial materials. Comprising a high-performance ball mill and air classifier, this complete grinding circuit delivers uniform particle size distribution for materials such as limestone, silica sand, calcium carbonate, and other powdered materials.

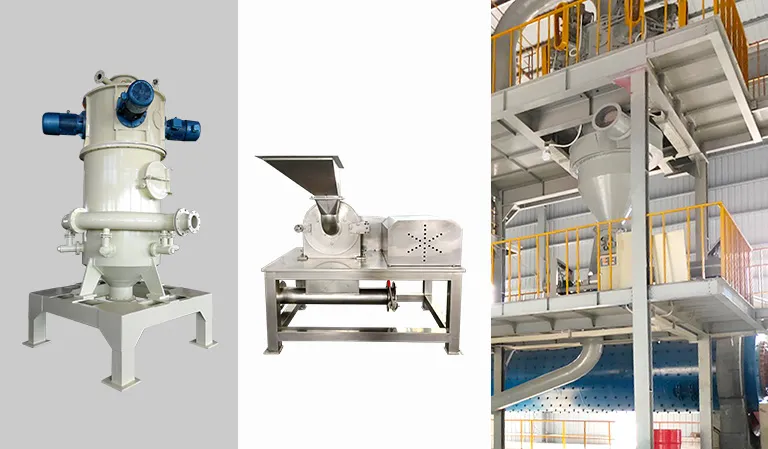

Fluidized Bed Opposed Air Jet Mill

Our advanced jet pulverizer machines are designed for high hardness, high purity and high added value.

Air Classifying Mill

Air classifier mill is ideal for fine powders of ceramics, abrasives, glass, minerals, and polymers.

Ball Mill and Air Classifier Production Line

Cooperate with the classifier to produce products of multiple particle sizes at the same time

Pin Mill

Multi-Rotor Mill

Surface modification of mineral powder is an inevitable product of the development of modern high-tech and new materials.

Vibration Mill

Ring Roller Mill

FAQ

What's the difference between a pulverizer and grinder?

While both are used for size reduction, a grinder (or grinding machine) is a broader term for equipment that reduces material to smaller pieces, often to a coarse or medium powder. A pulverizer is a specific type of grinder designed to crush material into a very fine or powdery consistency. Think of it this way: all pulverizers are grinders, but not all grinders achieve a fine enough result to be called pulverizers.

How to maintain my pulverizing machine?

Proper maintenance is key to longevity and efficiency:

Daily: Check for unusual noise or vibration, ensure all fasteners are tight, and clean the machine after use to prevent cross-contamination.

Weekly/Monthly: Inspect grinding elements (hammers, blades, screens) for wear and replace them as needed. Lubricate all bearings according to the manufacturer’s schedule.

Annually: Schedule a comprehensive inspection by a technician to check motor performance and internal components.

Always consult your machine’s specific operation manual for detailed procedures.

What industries use grinding machines?

Grinding and pulverizing machines are essential in numerous industries, including:

Pharmaceuticals: Creating fine powders for tablets and medications.

Food Processing: Grinding spices, grains, and sugars.

Chemicals: Reducing raw materials to reactive powders.

Mining & Minerals: Pulverizing ores and rocks for processing.

Recycling: Grinding plastics, wood, and other materials for reuse.

Agriculture: Producing animal feed and fertilizers.

What is a Pulverizer Machine Used For?

A pulverizer machine is specifically designed for the fine grinding of a wide variety of materials. Its primary function is to crush or grinder, and pulverize dry materials into a very fine powder. This process, known as pulverizing, is essential in industries like pharmaceuticals (for making medicines), food processing (for spices and flour), and chemicals to achieve a consistent and desired particle size for better reactivity or mixing.

How Does a Grinding Machine Work?

A grinding machine or grinder operates by subjecting material to mechanical forces that break it apart. Most industrial grinding machines use one or more of the following principles: impact (hammers or pins strike the material), attrition (material is rubbed between two surfaces), or shear (cutting force). The specific mechanism depends on the machine’s design, such as a hammer mill, classifier mill, or ball mill, all of which are types of pulverizing machines.

What Materials Can an Industrial Pulverizer Handle?

Industrial pulverizers are highly versatile and can process a vast range of medium-soft to hard materials. Common materials include:

Minerals: Limestone, talc, gypsum, calcium carbonate.

Chemicals: Crystals, pigments, resins.

Food Products: Sugar, grains, spices, nuts.

Pharmaceuticals: Active pharmaceutical ingredients (APIs), excipients.

The suitability depends on the machine’s construction and grinding mechanism, with options available for abrasive, heat-sensitive, or fatty materials.

What Are the Key Features to Look for in a Pulverizing Machine?

When selecting a pulverizing machine, consider these key features:

Particle Size Control: Ability to achieve your desired fine or ultra-fine powder consistency.

Grinding Mechanism: Choose between impact, attrition, or shear based on your material’s properties.

Hygiene & Design: Sanitary designs (e.g., easy-clean, USDA/FDA-approved) for food and pharma.

Durability: Robust construction with wear-resistant liners for abrasive materials.

Cooling Options: For heat-sensitive materials to prevent degradation during the grinding process.

Can a Pulverizer Machine Be Customized for Specific Needs?

Absolutely. Reputable manufacturers like EPIC Powder offer extensive customization for their pulverizer machines. Customization can include:

Specific Grinding Elements: Choosing the right hammers, liners, and screen sizes for your material.

Construction Materials: Using stainless steel for food-grade applications or specialized coatings for corrosion resistance.

System Integration: Designing the pulverizer to work seamlessly with other equipment like cyclones, dust collectors, and feeding systems in a complete production line.

We Has Helped Them Solve the Problem

Dry Grinding Machine Related Cases

Dry Pulverizer Machine Product Advantages

When the material enters machine, it is milled at high speed, which increases the evaporation surface area, has a large drying capacity, significant energy saving, high thermal efficiency of more than 70%.

The quality of dried products is uniform, the maximum dehydration capacity can reach 2t/h, product modification can also be carried out at the same time.

Negative pressure, dust-free, operation is simple, maintenance cost is low, variety of automatic protection functions and high reliability.

Request Your Pulverizer Machine Quote Today

Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Factory Address:

NO. 369, Road S209, Huanxiu , Qingdao City, China