As market competition intensifies, industrial upgrading is accelerating across various sectors. There is a growing demand for powders with more precise and specialized physical and chemical properties. Customized powders not only enhance a company’s competitiveness but also significantly improve user experience. In this context, fine powder processing technology plays a crucial role.

Epic Powder Machinery is a technology-driven manufacturing enterprise specializing in the research and development of fine powder processing solutions. Guided by the mission of “Finer Materials, Better World”, the company combines technological innovation with deep industry experience. With over 20 years of service to global customers, Epic Powder has built a comprehensive portfolio of customized powder processing solutions across multiple industries—including fillers, pigments, flame retardants, electronic materials, battery materials, non-metallic minerals, pharmaceuticals, food, construction, and solid waste recycling. Services include grinding and classification, coating and modification, dispersion and deagglomeration, among others.

Key Equipment Matrix (Partial)

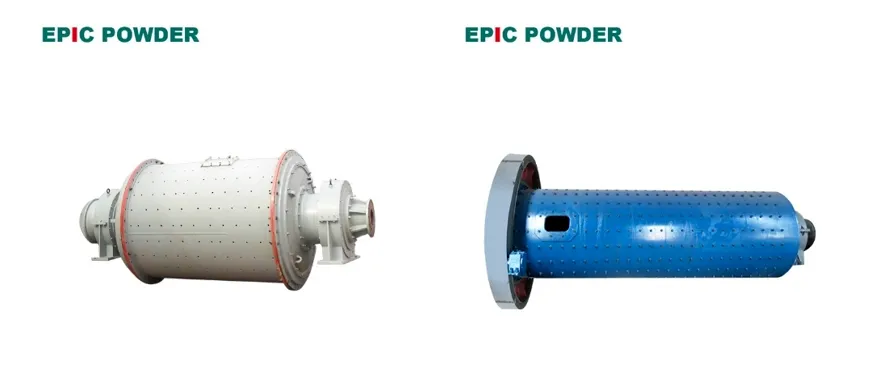

Ball Mill

The ball mill features continuous feed control to ensure feed stability, achieve maximum grinding efficiency, and reduce energy consumption. When combined with a multi-wheel classifier, it forms a ball mill classification system capable of producing fine powders with D97 from 5µm to 40µm. Production capacities range from 1 ton/hour to 100 tons/hour. The system can be designed for either pneumatic or mechanical conveying.

Application Areas:

Widely used for grinding and classification of calcium carbonate, calcined alumina, quartz, kaolin, zircon, bauxite, magnesite, rutile, and other minerals.

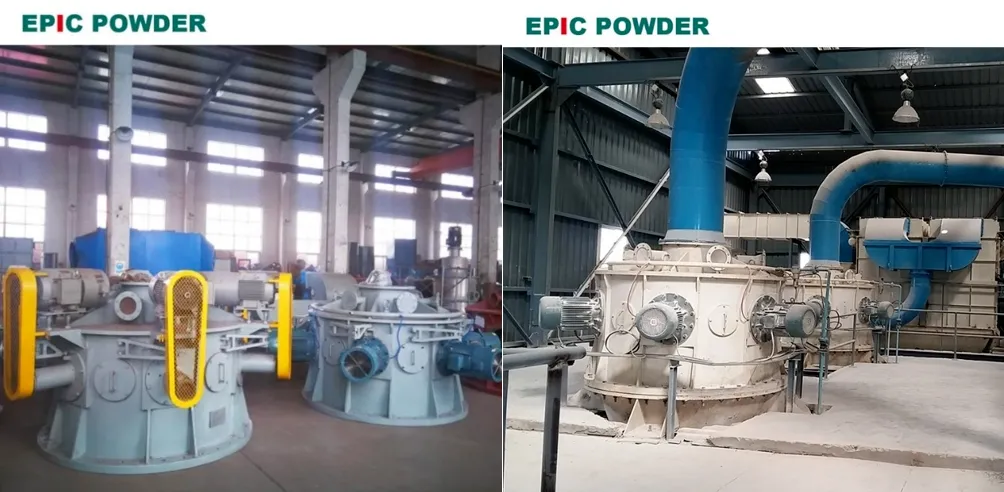

TS Air Classifier

The TS air classifier is an ultra-fine classifier, ideal for particle size D97 between 2 to 45 microns. It is designed to deliver high product fineness, high fine powder output, high efficiency, and low energy consumption. These performance benchmarks are achieved through optimized airflow dynamics, reduced material resistance, and multi-wheel design concepts. The classifier features an independent rotor housing for easy maintenance, extended service life, and low maintenance costs. It can be used in series with multi-stage classifiers. The HTS series rotor wheels are especially suited for high-strength applications. The rotor is mounted horizontally for easy access and control through a hinged maintenance door.

Application Areas:

Widely used in chemicals, minerals, metallurgy, ceramics, food, and other powder processing fields involving materials of varying hardness.

Jet Mill

Jet mills are ideal for low-temperature, media-free grinding, especially for heat-sensitive or low melting point materials. The final product has a narrow particle size distribution and can be finely controlled and adjusted. The entire system operates in a sealed environment, with no dust emissions, noise levels below 80 dB, and excellent environmental performance. Suitable for the ultrafine grinding of high-hardness, high-purity, and high-value-added materials. The resulting powders have good particle shape and uniform distribution.

Sintered Alumina Ceramic Wheel

The integrally sintered alumina ceramic wheel is a high-performance grinding component known for its outstanding hardness, wear resistance, and thermal stability. It is especially suitable for high-precision processing scenarios.

Total Solutions from Epic Powder

Epic Powder is committed to tailored solutions based on the specific needs of each customer, following the design philosophy of “one customer, one solution.” The company offers complete process and equipment solutions from raw material to finished product.

To further support customers, Epic Powder has established a professional laboratory and testing center to provide technical consulting services such as sample testing, project engineering design, equipment selection, and technical training. This helps customers integrate advanced technologies with cost-effective solutions.

Conclusion

Whether it’s upgrading traditional industries or making breakthroughs in emerging materials, Epic Powder always adopts a scenario-based approach to empower customers throughout the entire process—from process design to equipment delivery.

Today, powder processing production lines designed by Epic Powder have been successfully deployed in more than 50 countries and regions, including South Korea, Malaysia, Australia, the Philippines, Indonesia, India, Pakistan, Egypt, Turkey, the Middle East, Greece, Bulgaria, and Russia.

Looking ahead, Epic Powder will continue to optimize production processes, improve efficiency and product quality, and adopt advanced manufacturing and automation technologies to boost capacity and shorten delivery times. At the same time, the company will deepen its analysis of niche markets, better understand customer needs and industry trends, and grow together with its clients.