When the particle size of ultrafine powder materials reaches the micron or nanometer level, their physical and chemical properties change significantly. They demonstrate excellent performance such as uniform distribution, large specific surface area, and rapid chemical reactions. Powder technology is widely applied in the processing of battery electrode materials and even in battery manufacturing. Among them, cathode and anode materials are typical powder materials. Factors such as particle shape, internal structure, and surface properties greatly affect a battery’s energy density, output characteristics, and cycle life. Since the properties of the powder directly influence battery performance, the design of electrode materials and powder processing is critically important.

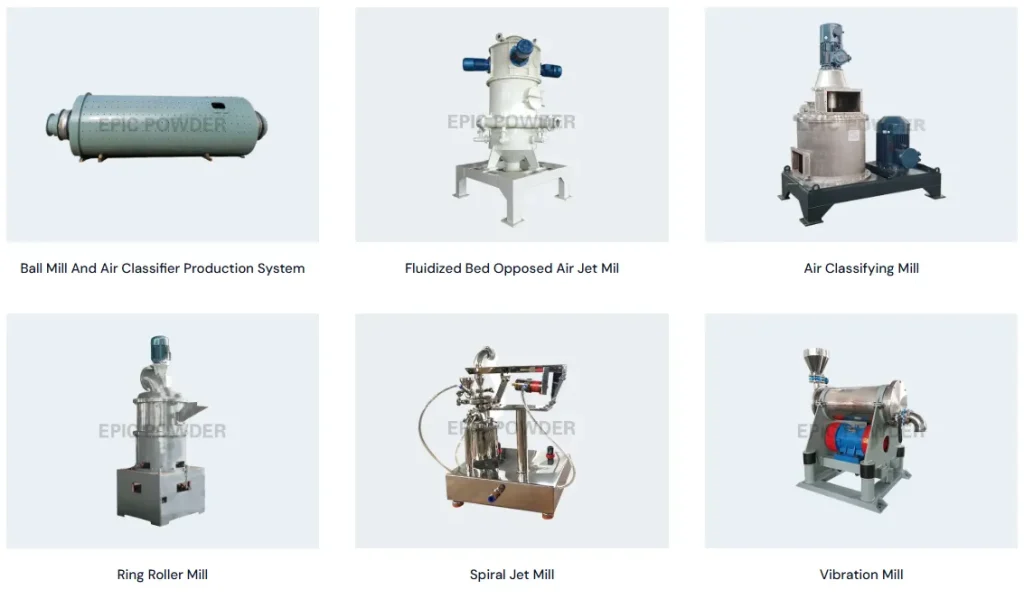

EPIC Powder Machinery Co., Ltd. (Qingdao Youmingke) is a technology-based manufacturing enterprise specializing in the research and development of fine powder processing technologies. The company has developed and manufactured a wide range of powder deep processing equipment, including air classifiers of various structures, ultrafine ball mills, ultrafine roller mills, jet mills, mechanical crushers, powder coating & surface modification machines, powder drying and de-agglomeration machines, and more.

The company provides a complete set of production processes and processing equipment, covering everything from raw materials to final products. We also offer a full range of services, including project consultation, sample testing, project engineering design, equipment selection, and technical upgrades.

Our design philosophy is market-oriented and customer-driven, aiming to tailor each solution to specific customer requirements—truly achieving “one customer, one design.”

Jet Mill

Fluidized Bed Opposed Air Jet Mill incorporates dense phase micronization using turbulent, free jets in combination with high efficiency centrifugal air classification within a common housing. This combination allows for enhanced comminution by high probability particle-on-particle impact for breakage and a high degree of particle dispersion for improved separation.

Air Classifier

The material is uniformly sent into the grinding chamber by the feeding system. It is strongly impacted by the high-speed rotating grinding disc. At the same time, it is subjected to the centrifugal force to collide with the crushing ring gear, and is subjected to various comprehensive forces such as shearing, friction, and collision. The material is ground, and the crushed material moves to the classification area with the airflow. The coarse and fine materials are separated through the classification wheel adjusted by the frequency conversion.

Three-in-One Laboratory Pulverizing and Classifying Equipment

Laboratory equipment is used for developing and processing new products, small-scale tests, quality control, and process optimization. This process offers flexibility, low cost, and easy cleaning. EPIC developed a series of small laboratory crushing equipment for universities, research institutes, and small enterprises.

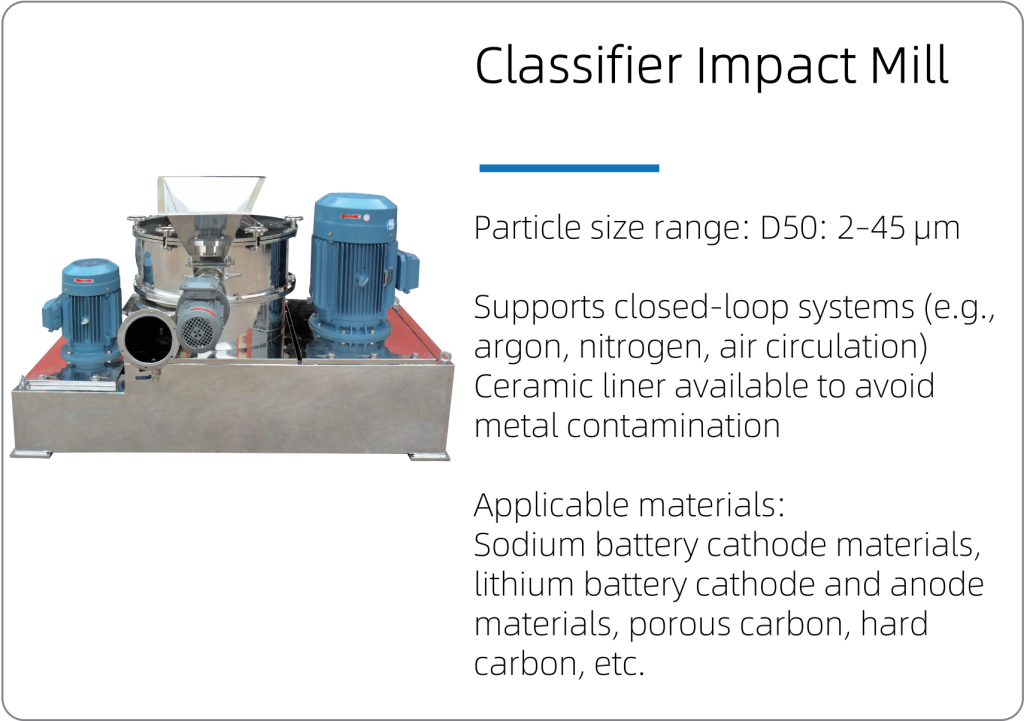

Classifier Impact Mill

The material is evenly fed into the grinding chamber, where it is impacted by the high-speed rotating crushing disc. It then undergoes forces like friction, shearing, and collision between the static disk and ring gear, resulting in crushing. The movable and static disks can be configured in various structures to meet the crushing needs of different materials. The structural forms we currently design include: hammer type, pin type, turbine type, and grinding disc type.