Calcium carbonate powder coating modification is an essential powder processing technology that plays a critical role in various industries. The main benefits of this technique include the following:

Improved Flowability and Dispersion

After coating modification, the surface of calcium carbonate powder becomes smoother and more uniform, reducing friction between particles. This significantly enhances the powder’s flowability and dispersion.

As a result, it improves processing efficiency, mixing performance, and product stability while reducing the formation of bubbles and shrinkage pores.

Enhanced Weather Resistance and Mechanical Properties

By adjusting the thickness and composition of the coating layer, the water absorption and chemical reactivity of calcium carbonate powder can be reduced, thereby improving its weather resistance.

The coating also increases the powder’s hardness, strength, and wear resistance, leading to better overall mechanical performance.

Increased Application Efficiency

Coated calcium carbonate powder exhibits improved adhesion and compatibility with matrix materials. This reduces filler loss and waste, resulting in higher application efficiency.

Additionally, the coating helps minimize dust pollution during production and simplifies operational handling.

Expansion of Application Fields

Coated calcium carbonate powder offers enhanced physical, chemical, and biological properties, making it suitable for a wide range of industries such as pharmaceuticals, food, plastics, and cosmetics.

For example, in plastic products, it improves mechanical strength and abrasion resistance; in cosmetics, it enhances stability and spreadability.

In summary, coating modification technology significantly improves the performance of calcium carbonate powder, broadens its applications, and provides strong support to materials science and engineering. With ongoing technological advancements, this method is expected to play an even greater role in more fields in the future.

Why Choose Epic Powder for Your Coating Modification Needs?

At Epic Powder, we specialize in advanced powder processing technologies, including high-quality coating modification solutions for calcium carbonate and other materials. Our innovative techniques ensure improved product performance, efficiency, and applicability across various industries.

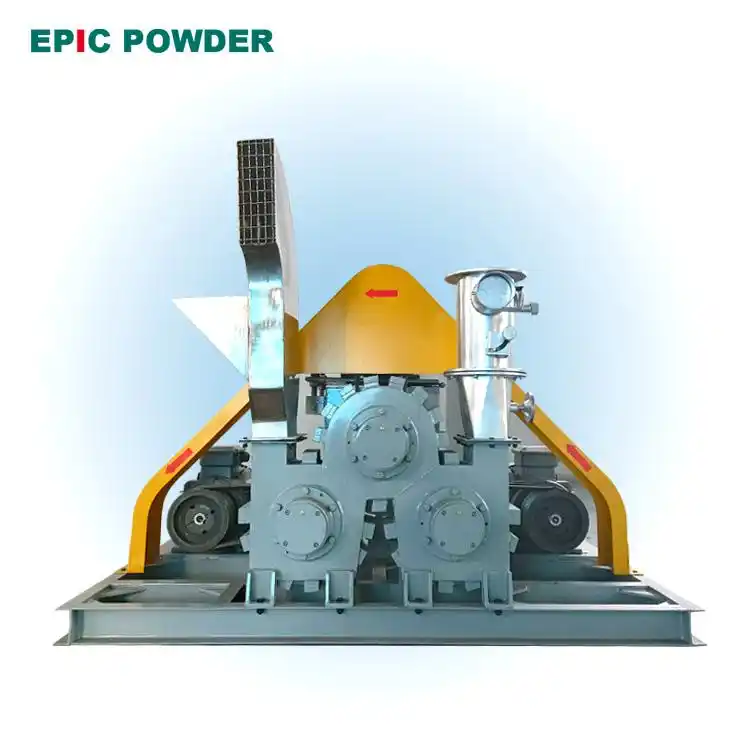

The below CRM coating machine can be used for coating various powders such as calcium carbonate (GCC and PCC), kaolin, talc, mica, graphite, barium sulfate, silica (white carbon black), magnesium hydroxide, zinc oxide, and aluminum oxide. The system is also suitable for a variety of solid and liquid coating agents, including aluminate coupling agents, titanate coupling agents, silane coupling agents, and stearic acid.

With a focus on research and customer-specific solutions, Epic Powder is committed to delivering superior quality and reliability. Trust us to enhance your products and processes with our expertise in powder modification. Explore the possibilities with Epic Powder—where innovation meets excellence.