Fillers not only reduce production costs and increase profit margins but also enhance properties such as high-temperature resistance, corrosion resistance, surface hardness, strength, wear resistance, flame retardancy, and insulation to some extent. For plastics, there are commonly used fillers like glass fiber, calcium carbonate, glass microspheres, silicate minerals and titanium dioxide.

Glass Fiber

Glass fiber is a commonly used filler in engineering plastics. Its main component is silicon dioxide, along with other derived metal oxides. The mainstream international production process is the tank furnace drawing method. Based on the alkali content in the glass, it can be classified into alkali-free, medium-alkali, and high-alkali glass fibers. Engineering plastics primarily use alkali-free chopped glass fibers and untwisted long glass fibers. After adding glass fibers, engineering plastics undergo the following changes:

Advantages:

Enhanced rigidity and hardness: The addition of glass fibers improves the strength and rigidity of plastics.

Improved heat resistance and heat deflection temperature: For example, adding glass fibers to nylon increases its heat deflection temperature by at least 30°C. Generally, glass fiber-reinforced nylon can withstand temperatures above 220°C.

Other advantages include: Improved dimensional stability and reduced shrinkage. Reduced warping deformation. Reduced creep. Lower moisture absorption.

Disadvantages:

Increased modulus of the product may reduce toughness. It adversely affects flame retardancy due to the wick effect, interfering with the flame retardant system and reducing its effectiveness. Exposed glass fibers can also diminish the surface gloss of plastic products.

The length of glass fibers directly affects material brittleness. Poorly processed short fibers may reduce impact strength, while well-processed long fibers can improve it. Selecting an appropriate fiber length is crucial to minimize brittleness.

The fiber content in the product is also critical. Industry standards typically use integer percentages such as 15%, 25%, 30%, or 50%, depending on the product’s application.

Achieving optimal mechanical properties and surface effects requires careful consideration of fiber diameter, length, surface treatment during modification, and fiber content.

Calcium Carbonate

Calcium carbonate products are divided into heavy calcium carbonate and light calcium carbonate. Heavy calcium carbonate, abbreviated as GCC, is produced by mechanically crushing natural calcite, limestone, chalk, shells, etc. It is called “heavy” because its sedimentation volume is smaller than that of light calcium carbonate. Currently, industrial production of GCC involves two processes: dry and wet methods. The dry method produces cost-effective and widely applicable products compared to the wet method.

Light calcium carbonate, abbreviated as PCC or precipitated calcium carbonate, is produced by calcining raw materials like limestone to produce lime (mainly calcium oxide and carbon dioxide). The lime is then hydrated to form lime milk (mainly calcium hydroxide), which is carbonated with carbon dioxide to precipitate calcium carbonate. Finally, it is dehydrated, dried, and pulverized. Alternatively, it can be produced by a double decomposition reaction of sodium carbonate and calcium chloride to form calcium carbonate precipitate, followed by dehydration, drying, and pulverization.

Calcium carbonate is one of the earliest inorganic fillers used to enhance and toughen PP. Micron-sized calcium carbonate has long dominated applications. Studies show that adding calcium carbonate increases the impact strength of PP but reduces tensile strength. Light calcium carbonate can improve both impact strength and yield strength, with stearic acid-treated PCC showing better results. Titanate coupling agent-treated calcium carbonate significantly enhances the impact strength of PP.

With the advent of nano-sized calcium carbonate, it has been found that nano-CaCO₃ can simultaneously enhance and toughen PP, with better toughening effects than micron-sized calcium carbonate. Research indicates that the morphology of nano-CaCO₃ greatly influences the mechanical properties of composites. Cubic nano-CaCO₃ improves impact performance, while fibrous nano-CaCO₃ enhances tensile properties. Nano-CaCO₃ also refines PP spherulites and promotes the formation of β-crystals.

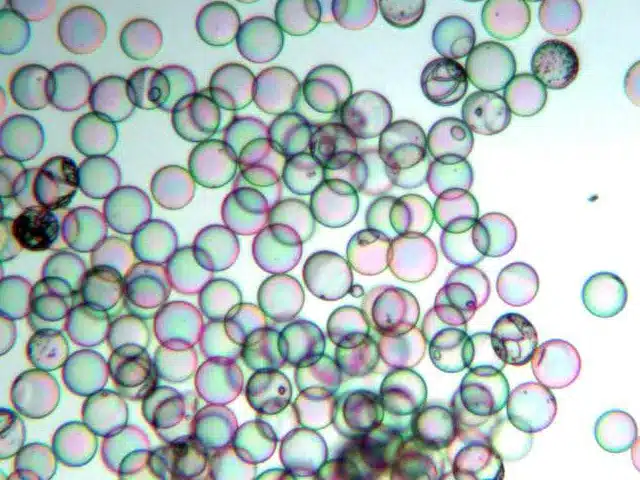

Glass Microspheres

Glass microspheres are a new type of silicate material, including solid and hollow varieties. Typically, glass beads with a particle size of 0.5–5 mm are called fine beads, while those below 0.4 mm are called microbeads. Microbeads come from various sources, such as fly ash glass microspheres, which are lightweight spherical particles extracted from fly ash. Their main component is silicon dioxide, along with various metal oxides. Fly ash glass microspheres offer advantages like high-temperature resistance and low thermal conductivity. When used as fillers in plastics, they enhance wear resistance, compression resistance, and flame retardancy. Their unique spherical shape improves processing fluidity, while their smooth surface enhances product gloss and reduces dirt adhesion.

Glass microspheres are widely used to reinforce and toughen PP. Studies show that as the content of glass microspheres increases, the tensile modulus, flexural strength, and modulus of single- and twin-screw extruded PP/glass microsphere composites increase linearly, while yield strength slightly decreases. Fracture strain improves at low content but declines rapidly at higher levels. The impact strength of both single- and twin-screw extruded materials improves and increases with glass microsphere content within a certain range. The impact strength of single-screw extruded materials is slightly higher than that of twin-screw extruded materials. The particle size of glass microspheres significantly affects the toughness of PP/glass microsphere composites.

Silicate Minerals

The most widely used and researched silicate minerals include talc, montmorillonite (MMT), and wollastonite, with attapulgite and zeolite also receiving considerable attention.

Talc and MMT are layered silicate minerals. Talc is a magnesium silicate mineral with a sheet-like structure. Generally, finer particles offer better dispersion, improving the material’s heat deflection temperature and surface smoothness. MMT has a larger interlayer spacing and is often used in the preparation of PP composites via the intercalation method. MMT can form a well-intercalated structure within the PP matrix, enhancing impact resistance and dimensional stability.

Attapulgite (ATP) is a chain-layered silicate. It is a natural one-dimensional nanomaterial silicate mineral, with basic structural units being needle-like or short fibrous single crystals. ATP can composite with polypropylene at both micron filler and nano reinforcement levels, improving the material’s mechanical properties. This new type of short clay fiber overcomes the drawbacks of general glass fiber-reinforced resins, such as poor fluidity, rough appearance, and severe wear on processing equipment, making it highly valuable for development.

Wollastonite is a single-chain silicate mineral, typically appearing as sheet-like, radial, or fibrous aggregates. Studies show that wollastonite-filled plastics not only improve mechanical properties but can also replace glass fibers, reducing costs. However, as the filler content increases, the composite’s hardness rises, causing significant wear on processing equipment.

Zeolite is a framework silicate mineral. Its rich pore structure allows it to adsorb or load functional particles, enabling the preparation of highly functional polypropylene composites and increasing product value. Therefore, developing PP/zeolite functional composites holds great potential and has become a hotspot in current research.

Titanium Dioxide

The chemical composition of titanium dioxide is TiO₂. Depending on its crystal form, it can be rutile or anatase. Rutile is the most stable crystal form, with a dense structure, and offers better hardness, weather resistance, and anti-chalking properties than anatase. It is stable against various chemicals in the atmosphere, insoluble in water, and has good heat resistance. Adding titanium dioxide not only improves product whiteness but also reduces UV damage, enhancing the light aging resistance of polypropylene. It also improves the rigidity, hardness, and wear resistance of products. However, its compatibility with crystalline materials like PP and PA is poor, making compatibilization modification necessary.

Epic Powder

As a well-established brand in the industry, Epic Powder Machinery is committed to customer-centricity, quality, and innovation. We are your reliable partner for long-term success. Choose Epic Powder for efficient, energy-saving, and environmentally friendly powder processing solutions! Contact us to learn more about our products!