Ultra-micro grinders are essential equipment in industries requiring fine particle processing, such as pharmaceuticals, chemicals, and food production. However, operational issues like poor feeding can disrupt efficiency and output. Understanding the root causes and implementing proper solutions ensures smooth operation and prolongs equipment lifespan. Regular maintenance, proper installation, and correct operation are key to preventing grinder feeding problems and ensuring long-term reliability. Below are the most common reasons for feeding problems and their corresponding fixes.

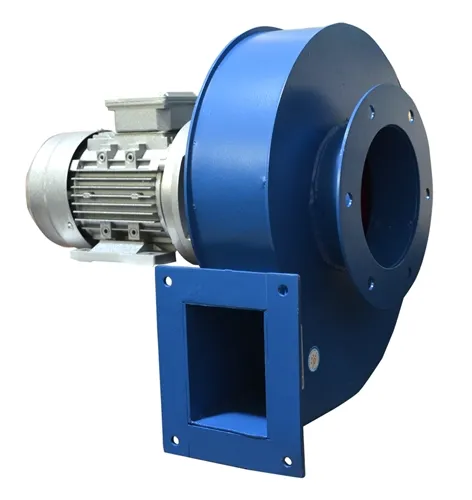

Damaged or Faulty Fan:

The fan is the core component responsible for feeding in an ultra-micro grinder. If the fan is damaged or malfunctioning, it cannot generate sufficient negative pressure, affecting the feeding performance. In this case, the damaged fan should be replaced.

Motor Failure:

The motor provides power to the grinder. If the motor is damaged or operating at insufficient speed, feeding will be hindered. Check whether the motor’s rotation direction is correct and ensure it operates within normal load limits. Replace the motor if necessary.

Belt Issues:

Worn or improperly tensioned belts can reduce transmission efficiency, leading to poor feeding. Regularly inspect the belt for wear, replace it if necessary, and adjust the tension appropriately.

Excessive Material Moisture:

High moisture content in the material can cause it to stick to the inner walls of the pipeline, increasing resistance and hindering feeding. Reduce material moisture and ensure it is adequately dried.

Oversized Material Particles:

Oversized particles may not enter the grinder smoothly, resulting in poor feeding. Pre-crush or screen the material to ensure an appropriate particle size.

Pipeline Blockage or Poor Design:

Pipeline Blockage: Accumulated material or debris in the pipeline can obstruct feeding. Clean the pipeline regularly to ensure smooth flow.

Excessive Bends or Length: Too many bends or excessive length in the pipeline can cause material to adhere to the walls, affecting feeding. Replace bent sections or optimize the pipeline design by reducing the number of bends and ensuring straight, unobstructed pathways.

Clogged Filter or Exhaust Port: A clogged filter restricts airflow, while a blocked exhaust port reduces negative pressure in the grinder. Regularly replace or clean the filter and inspect the exhaust pipeline for proper sealing to prevent blockages.

Air Duct or Dust Collection Bag Issues:

Blocked Return Air Duct: Dust or debris in the return air duct can impede feeding. Clean the duct to remove obstructions.

Dust Accumulation in Collection Bags: Excessive dust buildup in the collection bags can affect feeding. Clean the bags regularly to maintain efficiency.

Improper Installation or Sealing Issues:

Incorrect Installation: Improper positioning or misaligned components during installation can cause air leaks, reducing feeding efficiency. Ensure the grinder is installed correctly, with special attention to sealing components.

Poor Sealing: Aging, damaged seals or loose connections can lead to air leaks, lowering negative pressure in the feeding system. Inspect and replace seals as needed to ensure airtightness.

Improper Operation:

Excessive Feeding Speed: Feeding material too quickly can cause machine clogging and disrupt normal operation. Control the feeding speed to avoid overloading.

Mismatched Feeder Selection: If the feeder is not compatible with the grinder’s inlet width, material may not enter uniformly. Ensure the feeder is properly matched to the grinder’s specifications.

Conclusion

A malfunctioning ultra-micro grinder can significantly impact production efficiency. By systematically checking and addressing issues such as fan performance, motor condition, material properties, and pipeline design, operators can restore optimal feeding performance. If issues persist, consulting the equipment manufacturer or a professional technician is recommended for further troubleshooting.

For unparalleled performance and durability, consider Epic Powder‘s ultra-micro grinding solutions. Our equipment is engineered with:

Advanced anti-clogging designs to ensure consistent feeding. High-precision sealing systems to maintain optimal negative pressure. Customizable configurations for diverse materials, including heat-sensitive or adhesive powders like PE wax.

Contact Epic Powder for a tailored solution to your grinding challenges.