To purify quartz ore, the raw material must first be crushed and classified as a pretreatment step. The purpose of this is to achieve the initial separation of quartz from associated minerals and to provide raw materials with a suitable particle size range for subsequent processing and purification.

Quartz Crushing

The goal of crushing is to reduce the quartz ore to the required particle size to facilitate the release of impurities and enable further treatment. Crushing methods include mechanical crushing, electric pulse crushing, ultrasonic crushing, and thermal shock crushing.

Two key factors must be considered during crushing: effective mineral dissociation and secondary contamination.

The traditional mechanical method involves using a jaw crusher or cone crusher to reduce the mineral to the desired particle size, resulting in irregular, angular particles. A jaw crusher is typically used for coarse crushing, a cone crusher for medium and fine crushing, and an impact crusher for fine crushing and coarse grinding.

To avoid secondary contamination by iron impurities and to enhance dissociation, alternative methods such as thermal crushing, high-voltage pulse crushing, and ultrasonic crushing can be used. However, these methods generally come with higher energy consumption and cost.

(1) Pulse Discharge Crushing

Compared to traditional mechanical methods, pulse discharge crushing offers significant advantages for rock processing. It mainly includes hydroelectric effect crushing and electric pulse crushing. The shock waves generated by high-voltage discharge cause rocks to fracture along grain boundaries and target mineral inclusions selectively. This enhances impurity release and aids subsequent processing while preserving the mineral’s particle size and morphology.

Pulse discharge crushing is typically performed in a water medium, making it dust-free and environmentally friendly. Moreover, it reduces iron contamination compared to traditional crushing. The impurity content of K, Ti, and Fe is lower after electric crushing than after mechanical treatment.

DAL et al. applied high-voltage pulse electric crushing to separate trace impurity minerals (less than 1% content) from single quartz minerals. Their research showed that this method effectively separates different minerals in quartz ore. The resulting particles are more spherical and contain internal pores that connect to inclusions.

(2) Ultrasonic Crushing

Ultrasonic crushing utilizes mechanical energy from ultrasound. When the ultrasonic probe operates in a liquid medium, cavitation occurs, producing many small bubbles. The immense pressure released when these bubbles burst peels impurities from the particle surfaces.

(3) Thermal Crushing

Thermal crushing involves heating quartz ore to a specific temperature, causing it to expand or undergo phase changes. This creates microcracks that weaken the ore’s mechanical strength, making it easier to crush.

2. Quartz Grinding

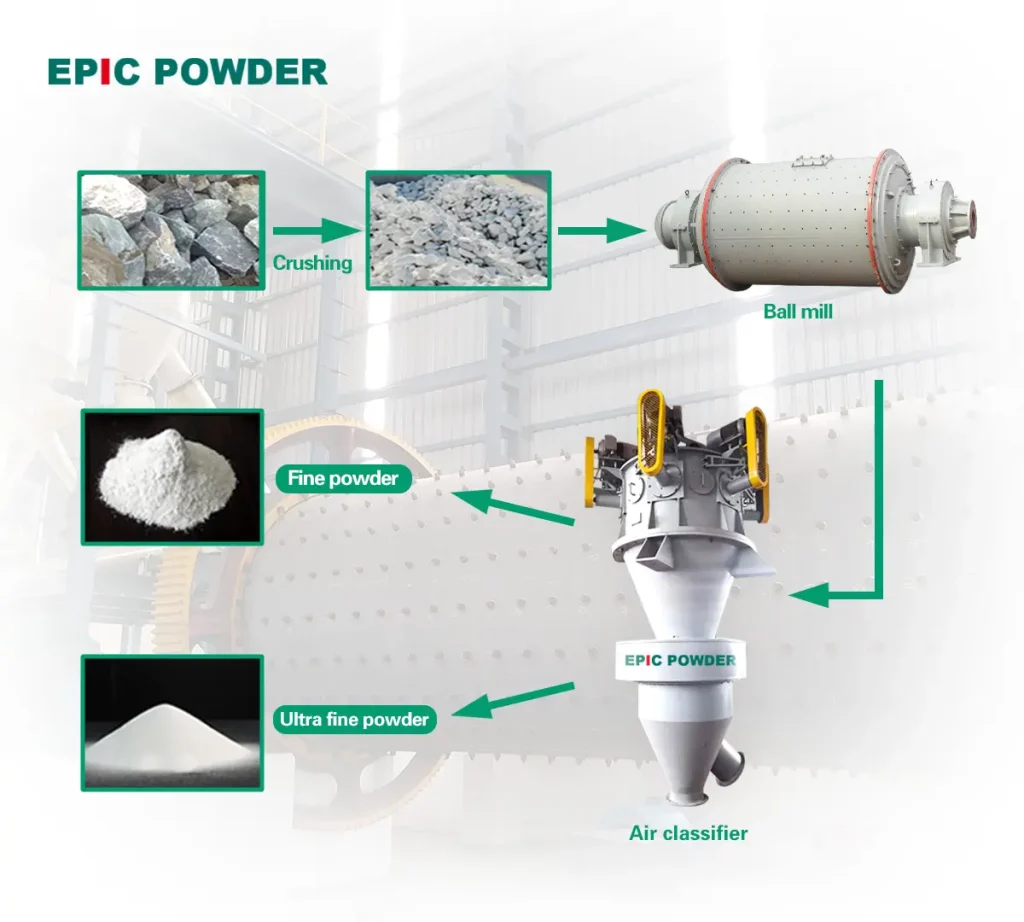

Grinding and classification follow the crushing process. Since grinding reduces ore from coarse to fine, a suitable grinding and classification method is required to timely separate particles that meet size specifications, avoid over-grinding, and improve operational efficiency and yield.

Epic ball mill + classifier production line is particularly suitable for ultra-fine grinding of quartz. It offers high product whiteness, good particle shape and gloss, stable quality indicators, and strong control over particle size distribution.

However, since ball mills and classifiers serve different functions and are usually produced by different manufacturers, discrepancies in production concepts (e.g., output capacity) may arise. Thus, proper equipment matching is critical in design and selection. Poor matching can lead to functional limitations, high energy consumption, and low efficiency. On the other hand, good integration can enhance overall system performance, yielding high efficiency with less effort.

Due to the high hardness of quartz, it causes significant wear on equipment and may contaminate the product. To prevent re-contamination—especially in electronic-grade high-purity silicon micropowder production—all equipment, including cavities, pipelines, and static components, must be lined with ceramic or organic wear-resistant materials.

Ball mills typically use alumina or stone liners and grinding media such as zirconium balls or agate to reduce contamination from iron or aluminum impurities.

Grinding aids

Quartz is hard and highly wear-resistant. Particularly in fine grinding, relying solely on mechanical grinding may not produce powders of the desired fineness. Therefore, grinding aids are often added to improve the efficiency of the process. These additives reduce slurry viscosity, enhance fluidity, and increase the yield of qualified fine particles.

Common grinding aids include triethanolamine, DA dispersant, stearic acid, ammonium chloride, sodium chloride, alcohol, sodium oleate, sodium silicate, dodecylamine, and also tested are fatty alcohol polyoxyethylene ether and dodecyl trimethyl ammonium chloride.

It’s important to note that different industries and applications require specific particle size distributions for high-purity quartz. For instance, quartz crucible manufacturing in the semiconductor industry requires quartz sand sizes between 0.180 mm and 0.125 mm. Therefore, precise control over particle size during grinding is essential to avoid over-grinding.

Epic Powder Machinery is a leading manufacturer of ultra-fine grinding and classification equipment. With decades of experience and European core technology, we specialize in providing customized solutions for high-purity quartz and other hard materials. Our advanced systems, including jet mills, ball mills, and precision classifiers, are widely used in the mineral, electronics, and chemical industries. We are committed to delivering efficient, clean, and contamination-free powder processing solutions to meet the most demanding application standards.