What is Coffee Powder?

Coffee powder is the finely ground form of coffee beans, a globally cherished beverage raw material. Coffee beans undergo roasting and grinding to produce coffee powder, which varies in particle size depending on the brewing method. Coffee powder’s texture influences extraction rate, flavor, aroma, and overall cup quality. The global coffee market value exceeded USD 500 billion in 2024, driven by demand for premium and specialty coffee products that require precise powder characteristics for optimal brewing. Ultrafine grinding of coffee powder enhances extraction efficiency and flavor clarity.

What Are the Uses of Coffee Powder?

Coffee powder is primarily used for brewing beverages ranging from espresso to drip coffee and instant products. Its particle size and consistency directly impact brewing efficiency, extraction uniformity, and flavor profile. Beyond drinks, coffee powder finds use in cosmetics, food flavoring, and pharmaceuticals for its antioxidant and aromatic properties. The industry favors powders with uniform particle size and moisture content to enhance shelf life and sensory experience.

Why Does Coffee Powder Need Ultrafine Grinding?

Ultrafine grinding of coffee powder enhances extraction efficiency and flavor clarity. Finer particles offer larger surface area contact with water, enabling faster and more complete dissolution of soluble compounds during brewing. This results in richer aroma, balanced acidity, and smoother taste. However, excessively fine powder can cause over-extraction and bitterness. Hence, precise particle size control in the ultrafine range microns is critical for premium coffee quality.

Why Use jet Milling for Coffee Powder?

Jet Milling is ideally suited for coffee powder grinding because:

- It achieves consistent ultrafine particle size distribution with sharp cut-offs.

- The process generates minimal heat, preserving volatile coffee oils and aromas essential to flavor.

- Dry processing reduces powder contamination and facilitates hygiene compliance.

- Integrated classification allows real-time particle size control, ensuring batch-to-batch consistency.

- Closed-loop dust control improves operator safety and environmental compliance.

Technical data show advanced jet mills achieving particle size distributions below 100 microns while maintaining coffee temperatures under 40°C, preserving aroma and minimizing degradation.

Important Considerations in Coffee Powder Jet Milling

Several factors must be optimized during coffee powder jet Milling:

• Temperature Control: High grinding temperatures degrade aroma compounds. Water-cooling systems in mills help maintain temperatures below 40°C.

• Electrostatic Charge Management: Coffee powder is prone to static charge buildup causing clumping and uneven flow. Technologies like ionization and anti-static coatings mitigate this issue.

• Moisture Content: Uniform low moisture prevents caking and preserves powder flow characteristics.

• Machine Hygiene: Regular cleaning prevents residue buildup and flavor contamination.

• Particle Size Adjustment: Precise classifier tuning is necessary to match target particle size for the intended coffee brewing method.

Addressing these factors enables manufacturers to produce high-quality coffee powder that delivers superior sensory experience and brewing consistency.

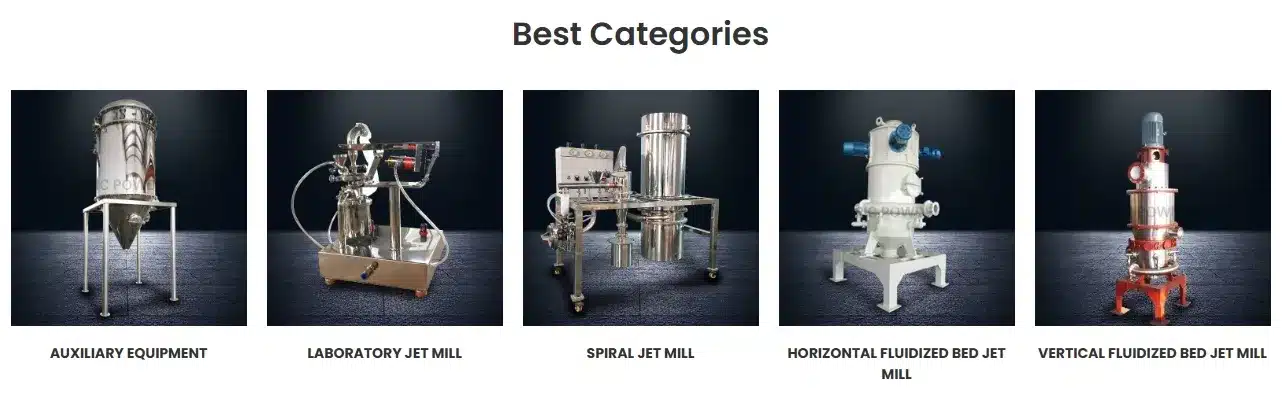

EPIC Powder Machinery’s Jet Mill Performance for Coffee Powder

EPIC Powder Machinery offers jet mills specifically designed for coffee powder ultrafine grinding. Our equipment excels at:

Producing ultrafine coffee powder with particle sizes consistently.

Integrating advanced electrostatic discharge and dust control technologies.

Providing automated control systems for stable, precise particle size and density control.

Featuring durable components that ensure long-term performance in demanding coffee powder production environments.

EPIC’s jet mills have empowered leading coffee powder manufacturers worldwide to achieve improved product quality, consistent grind texture, and enhanced aroma retention, meeting the needs of specialty coffee markets and industrial applications alike.

Epic Powder

Epic Powder offers a complete after-sales service system, covering everything from equipment installation and commissioning to operation training, maintenance, and support. As a well-established brand in the industry, Epic Powder Machinery is committed to customer-centricity, quality, and innovation. Choose Epic Powder for efficient, energy-saving, and environmentally friendly powder processing solutions.

Contact us to have a tailoe-made solution!