Catalysts are key materials that enable countless chemical reactions in industries ranging from petrochemicals to environmental technologies. Their effectiveness relies heavily on precise physical attributes such as particle size, surface area, and purity. At Qingdao EPIC Powder Machinery Co., Ltd., we recognize that manufacturing catalysts with consistent particle characteristics is crucial for ensuring their optimal performance and longevity. Air classifier mills have become essential equipments in catalyst production. They integrate grinding and classification into a single, continuous process. This article explores the fundamental reasons why air classifier mills are ideally suited for catalyst manufacturing. The principles behind their operation, and the advantages they bring from both a technical and industrial perspective.

Understanding Catalysts and Their Particle Requirements

Catalysts function by providing active surface sites to accelerate chemical reactions without being consumed. Therefore, the catalyst’s particle size distribution (PSD) and morphology directly affect its catalytic efficiency. Smaller particles with high surface area facilitate better reactant contact, enhancing activity. Simultaneously, controlling the upper size limit prevents operational issues like pressure drops or uneven flow in catalytic reactors.

Moreover, catalyst powders must remain chemically stable, structurally intact, and free from contamination during processing. Any deviations may degrade catalytic performance or shorten the catalyst’s operational lifespan. Hence, tight control of particle size distribution and maintaining product purity are critical in catalyst production.

The Role and Operating Principle of Air Classifier Mills in Catalyst Production

Air classifier mills combine grinding and classification processes seamlessly. Raw catalyst material enters the mill where it is subjected to mechanical impacts from rotating hammers or pins within a high-velocity airflow. This airflow suspends and transports particles into the classifier section, where a dynamic classifier wheel sorts particles by size.

The classifier wheel’s rotational speed applies centrifugal force, segregating coarser particles from finer ones. Larger particles are returned to the mill for further grinding, while appropriately sized fine particles exit as the final product. This closed-loop system maintains continuous, precise control over particle size while maximizing throughput.

The grinding gas, usually clean compressed air or inert gas, also serves to cool the system. Typically, the mill operates at temperatures below 60°C, protecting the catalyst powders’chemical and physical integrity. Furthermore, the use of advanced classifier designs and wear-resistant materials—such as ceramic or silicon carbide linings—ensures minimal contamination and long-term durability.

Key Advantages of Using Air Classifier Mills for Catalyst Manufacturing

Air classifier mills deliver several compelling benefits for catalyst producers. Firstly, their integrated grinding-classification process provides unmatched control over particle size distributions. By fine-tuning the classifier wheel speed and airflow parameters, manufacturers can easily target narrow PSDs that meet specific catalytic performance criteria.

Secondly, the closed-loop circulation system reduces over-grinding and energy waste, improving overall operational efficiency. The continuous separation of oversized particles ensures material is optimally processed, enhancing productivity and guaranteeing consistent product quality even during large-scale production runs.

Next, the low-temperature operation protects heat-sensitive catalyst materials from degradation. This is especially important for catalysts containing organometallic compounds or other volatile components that could otherwise lose effectiveness if exposed to excessive heat.

Finally, the scalability and flexibility of air classifier mills accommodate diverse catalyst types and production volumes. Whether manufacturing FCC catalysts, hydrogenation catalysts, or specialty environmental catalysts, the equipment can be tailored to specific material properties and output requirements, supporting innovation and customization.

Practical Applications and Industry Impact

Air classifier mills are highly effective in producing catalysts used for fluid catalytic cracking (FCC), hydrodesulfurization, ammonia synthesis, and emission control systems among others. The precise PSD control leads to catalysts that optimize reaction rates, improve selectivity, and extend catalyst life cycles.

In environmental applications, for example, finely classified catalysts facilitate effective reduction of pollutants in automotive exhaust systems and industrial flue gases. Meanwhile, in petrochemical refining, catalyst particle uniformity ensures stable flow dynamics and consistent product conversion rates.

The continued industrial demand for high-performance catalysts ties directly to advancements in milling technologies. Air classifier mills allow manufacturers to consistently produce catalyst powders meeting stringent regulatory and operational standards. In this case, it will strengthen their competitiveness and supporting sustainable industrial processes.

Conclusion

The intricate requirements of modern catalyst production necessitate equipment capable of delivering tight particle size control, efficient grinding, and contamination avoidance. Air classifier mills excel in fulfilling these demands by combining precision classification with robust grinding in a single, energy-efficient operation.

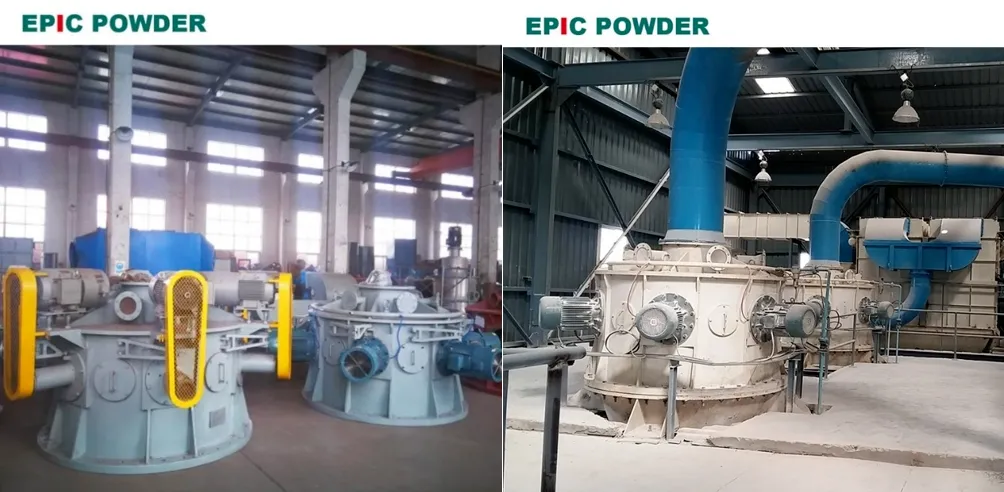

At Qingdao EPIC Powder Machinery Co., Ltd., we provide state-of-the-art air classifier mills engineered to optimize catalyst milling processes. Our equipment enables manufacturers to achieve consistent catalyst quality, improve process efficiency, and maintain competitive advantage in a rapidly evolving market.

For further technical guidance or tailored equipment solutions, our experts are ready to assist. Partner with EPIC Powder Machinery to harness advanced air classification technology and elevate your catalyst production capabilities to the highest standards.