In the realm of grinding equipment, ball mills are widely used machines. Based on their operational methods, they are primarily categorized into two types: continuous type and batch type. These two types exhibit distinct differences during the grinding process, particularly in feeding and discharging stages. These differences directly impact the final product’s particle size uniformity, which plays a crucial role in subsequent industrial production processes.

1. Continuous Ball Mills: Automated Control for Superior Particle Uniformity

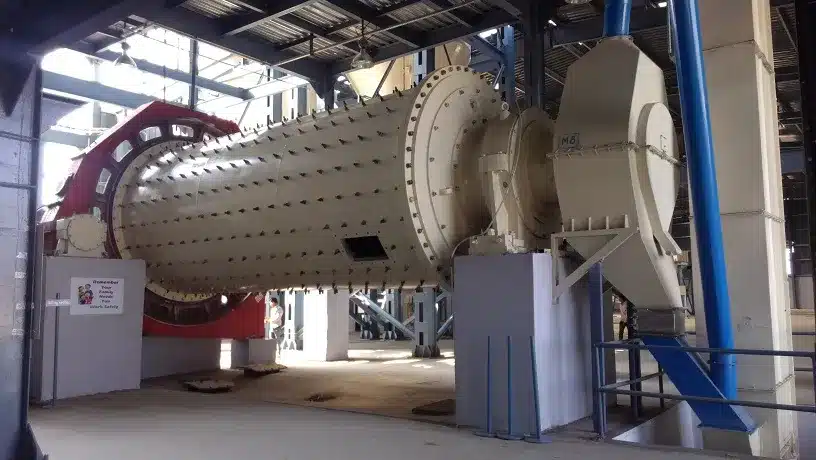

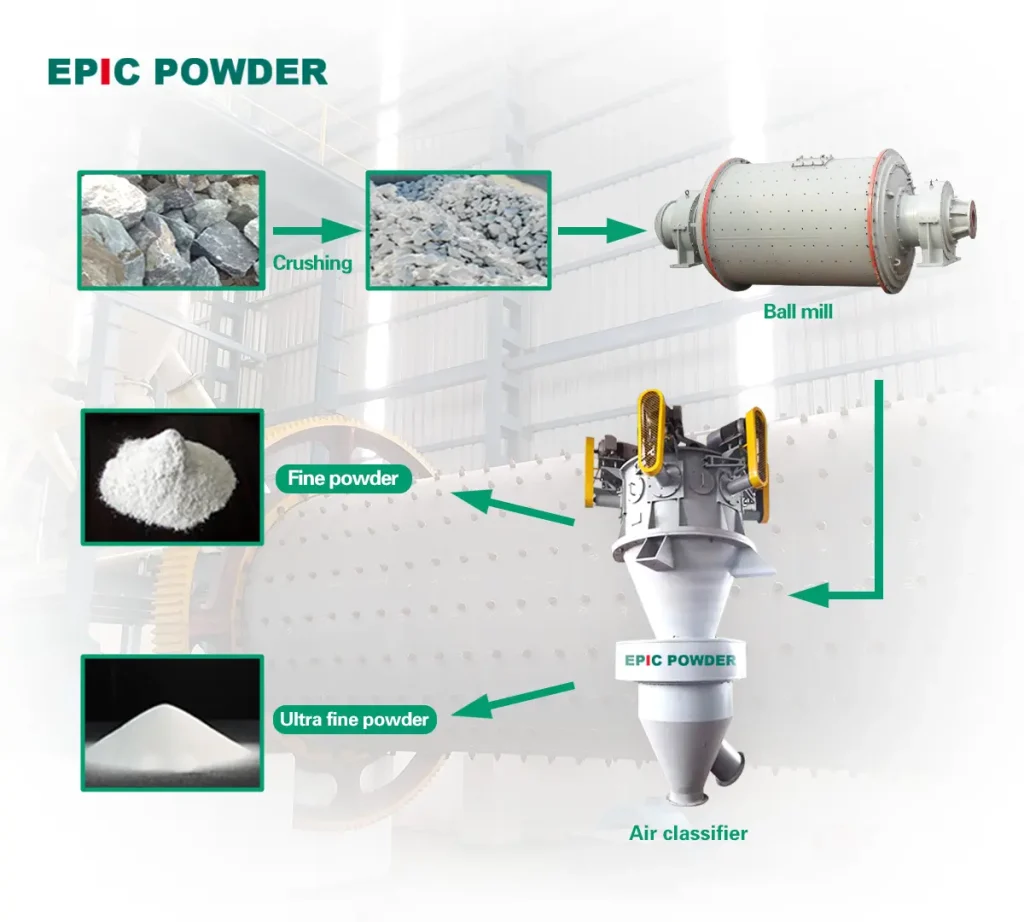

The most notable feature of continuous ball mills is the uninterrupted material processing from feeding to discharging. During feeding, materials continuously enter the mill without interruption. At the discharge end, they don’t simply expel materials after a set grinding period. Instead, they determine discharge based on whether the material has reached the required fineness. Only when the material meets the specified particle size standards is it discharged from the mill. If the material hasn’t achieved the required fineness, it continues grinding inside the mill until it meets the standards.

This size-based discharge method results in remarkably uniform particle size at the discharge end of continuous ball mills. Each batch of discharged material undergoes strict screening, ensuring only properly sized particles are released, preventing unqualified materials from mixing in. In practical production, this uniform discharge size brings numerous benefits. For instance, subsequent processing stages don’t require additional screening or grinding, saving both production time and costs. Meanwhile, consistent particle size ensures stable quality in downstream products, preventing performance variations caused by significant size differences.

2. Batch Ball Mills: Time-Based Discharge with Inevitable Size Variations

Unlike their continuous counterparts, batch ball mills operate intermittently. During feeding, a specific amount of material is loaded at once, after which the feeding port closes and grinding begins. Throughout the grinding process, no new materials are added, and no discharge occurs. When the preset grinding time elapses, all materials are discharged simultaneously, regardless of their actual grinding progress inside the mill.

This operational approach leads to significant variations in discharge particle size from batch ball mills. During the grinding process, material distribution and grinding intensity are uneven within the mill. Materials closer to grinding media might be ground finer, while those farther from grinding media or shielded by other particles might receive insufficient grinding, resulting in coarser particles. When the preset time concludes, these variously sized materials are discharged together, creating a final product mixture containing both qualified fine particles and unqualified coarse particles. In many production scenarios requiring high particle size uniformity, using them necessitates an additional screening step after discharge to separate coarse particles for regrinding, undoubtedly increasing production complexity and costs.

3. Production Efficiency: Continuous Processing vs. Intermittent Operation

Beyond differences in discharge size uniformity, continuous and batch ball mills also vary in production efficiency. Continuous ball mills, capable of uninterrupted feeding and discharging without significant time investment in these stages, achieve higher output per unit time, making them more suitable for large-scale continuous production. Batch ball mills require frequent cycling through feeding, grinding, and discharging operations, with inevitable intervals between cycles resulting in lower hourly throughput. This makes them more appropriate for smaller-scale production scenarios where continuous operation isn’t essential.

4. Selection Guide: Matching Equipment to Production Requirements

When selecting ball mill equipment in practice, production requirements should guide the decision. For large-scale production demanding high particle size uniformity and continuous operation, continuous ball mills prove superior. For smaller-scale operations where production continuity isn’t crucial, or when processing materials requiring extended grinding periods, batch ball mills might be more suitable. Material characteristics – including hardness, moisture content, and other properties – should also be considered as they influence grinding efficiency and discharge quality.

Conclusion

In summary, the different feeding and discharging methods between continuous and batch ball mills create distinct differences in discharge particle size uniformity and production efficiency. Understanding these differences helps enterprises select appropriate ball mill equipment based on their specific production needs, ultimately enhancing production efficiency, ensuring product quality, and reducing operating costs.

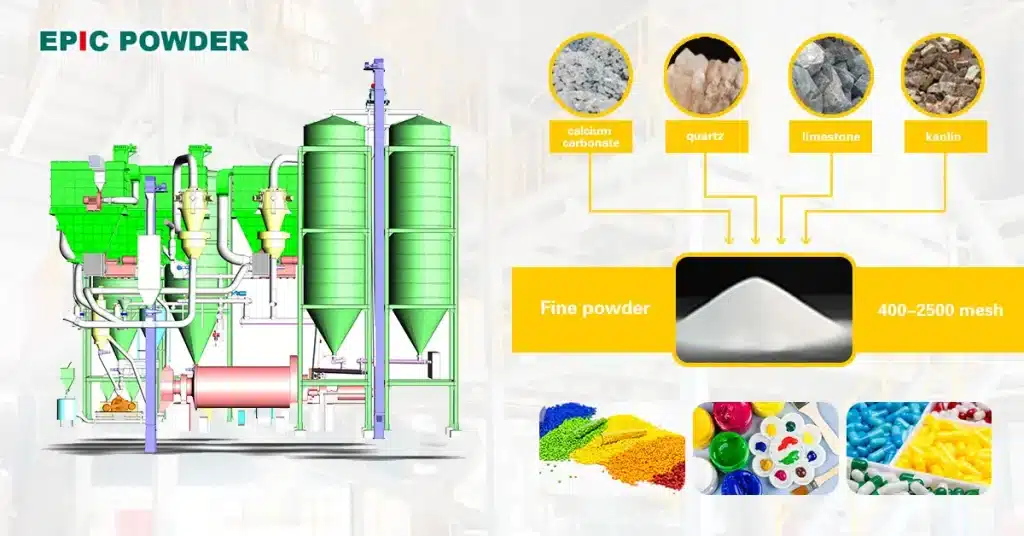

Epic Powder

Epic Powder Machinery‘s innovative mill design sets itself apart from traditional cement and metallurgical equipment, meeting German standards for superfine filler-grade mineral processing. We have optimized multiple aspects to achieve superior performance: the aspect ratio prevents over-grinding while ensuring optimal results; the jaw plate opening design enhances fineness with smaller grinding media; and the slab-type discharge system ensures smooth material flow without residual grinding. The mill operates without requiring cylinder cooling, and when combined with our classifier, it forms a dust-free closed system with negative pressure conveyance.

For specialized applications, ball mills by Epic Powder can be lined with alumina ceramics, quartz, SILEX, or other custom materials to eliminate iron contamination when processing hard minerals. With rational grinding media allocation, high filling rates, and optimized drive systems, we maximize energy efficiency while maintaining exceptional grinding performance. Additionally, grinding aids are supported for ultrafine powder production, ensuring higher efficiency throughout the process. Each component – from lining design to media selection – follows German engineering standards to minimize wear, reduce breakage, and deliver reliable, high-yield operations. Contact us now for your tailor-made solution.