Bentonite is a water-containing clay rock with montmorillonite as its main component. It possesses exceptional swelling, adsorption, cation exchange, catalytic reactivity, adhesion, suspension, and ductility properties. These unique characteristics have earned it the nickname “all-purpose clay.”

1. Drilling Fluid

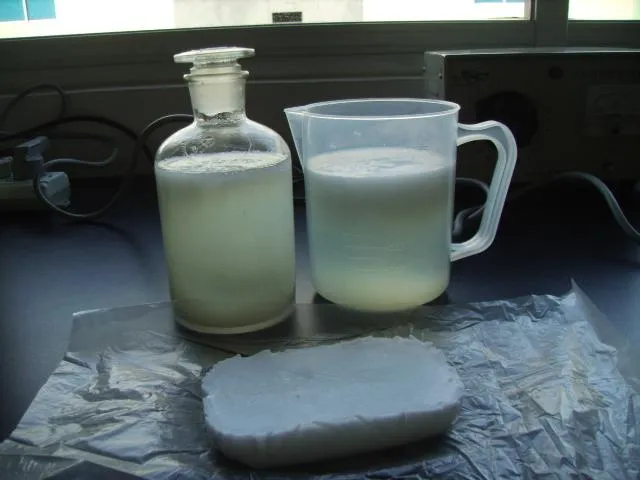

Bentonite has excellent suspension and compressibility in solution. When mixed, it forms a colloidal suspension with great fluidity. After mixing stops, it naturally forms a three-dimensional colloidal network without settling or separating water. It is especially suitable for use in drilling fluids. Statistics show that, on average, around 8 tons of bentonite are used per well.

2. Binder for Metallurgical Pellets

Bentonite offers strong moisture absorption, dispersion, lubrication, and thickening properties. It enables bonding of iron ore concentrate with water and serves as an essential binder for metallurgical pellets.

3. Sand Binder

Calcium-based bentonite features excellent ductility, reusability, wet compressive strength, moldability, and die strength. It helps prevent defects in castings such as sand inclusion, scabbing, block falling, and mold collapse. It is widely used in wet and dry casting processes, making it a preferred binder for precision casting.

4. Feed Additive

Bentonite contains over 10 types of mineral elements, many of which are essential nutrients for poultry. Adding bentonite to feed improves animal vitality, promotes shiny feathers, increases survival rates, and enhances disease resistance.

5. Cat Litter

Cat litter is the largest application of bentonite in Europe, accounting for 29% of total trade volume. Bentonite cat litter quickly absorbs and clumps around cat waste. It has excellent absorption capacity for liquids and odors, uniform particle size, and does not dissolve after absorbing moisture.

6. Pharmaceutical Suspension Agent

Suspensions have good bioavailability and are ideal for patients who struggle with swallowing, such as children and the elderly. Bentonite acts as a high-performance suspending agent in pharmaceutical formulations.

7. Antidiarrheal Medication

Montmorillonite, bentonite’s main component, has a layered structure and uneven charge distribution, allowing it to selectively adsorb viruses, pathogens, and toxins in the digestive system. For example, SMECTA, a well-known product by French company Ipsen, is a gastrointestinal protective film based on montmorillonite.

8. Moisture Absorber

Bentonite desiccants offer adsorption activity, static dehumidification, and odor control. They are widely used in items unsuitable for sealed or gas-phase storage, such as optical and electronic equipment, healthcare products, and food packaging.

9. Animal and Vegetable Oil Decolorizer

When activated with a strong oxidant, bentonite becomes an active, self-degradable clay with powerful adsorption and decolorization capabilities. It is used for refining oils such as soybean oil, cooking oil, peanut oil, and rapeseed oil, offering deodorization, detoxification, and oxidation resistance.

10. Wine Clarifying Agent

Calcium-based bentonite is used to clarify wine more effectively than traditional methods like glue, heat filtration, or aluminum sulfate treatment. It preserves the wine’s original ingredients and ensures long-term clarity, gloss, and stability for over two years without mold or sediment.

11. Beverage Clarifier

Bentonite is used in fruit juice processing to absorb polyphenols (e.g., tannins in red wine) and colloidal biomolecules like proteins. It also complexes with metal ions to remove non-biological turbidity, resulting in clear beverages.

12. Soy Sauce Processing Aid

Adding bentonite at 1% of the raw soy sauce material weight can increase the carbohydrate conversion rate and total nitrogen utilization, while also improving its nutritional value.

13. Vinegar Clarifier

A reactant made from chitosan and bentonite effectively removes turbidity and sediment from aged vinegar, enhancing clarity and stability.

14. Chicken Essence Decolorizer

Modified bentonite can be widely used in the production of chicken essence. After treatment with carboxymethylcellulose, the modified bentonite is used in a decolorization test on the saccharified starch solution. It does not adsorb glucose water but reduces the arsenic content in the solution by 87% and the crude protein content by 27%, thereby improving the overall quality of chicken essence.

15. Organometallic Catalyst

Due to its fine particle size, large surface area, and mildly acidic to alkaline physical properties, bentonite serves as an ideal catalyst for organic metal reactions.

16. Food Packaging Film

A series of nanocomposite plastics have been successfully developed using natural mineral bentonite as a dispersing medium, with acrylic resin, polyester, polyethylene, polyaniline, polyurethane, and other materials. Among these, polyester-based 6 nm plastic films exhibit excellent barrier properties, mechanical strength, and light transmittance, making them ideal for food packaging.

17. Retention and Drainage Aid in Papermaking

Bentonite’s layered structure has negatively charged surfaces and positively charged edges, allowing it to effectively adsorb colloidal particles. When hydrolyzed in water, its cations (e.g., potassium ions) form negatively charged particles that are stable across various pH levels. These properties make bentonite widely used in papermaking processes for retention aids, drainage improvement, and water treatment.

18. Waste Paper Deinking Agent

In paper recycling systems, bentonite — either used alone or in combination with light calcium carbonate — can bind to and remove ink and adhesives from chemical fibers. This reduces the accumulation of residues on papermaking machine components and improves the efficiency of the recycling process.

19. Rheological Control Agent for Printing Paper Coatings

When montmorillonite (a component of bentonite) is dispersed in strong electrolytes, surface hydration and double-layer interactions cause interlayer swelling. This expansion gives it thickening properties in aqueous systems, making it useful as a rheological control agent in printing paper coatings.

20. Filler in the Papermaking Industry

Bentonite is used as a filler in low-grade paper production, achieving high filling levels without compromising paper strength — especially tear resistance. Modified bentonite is also suitable for use in low-gloss paper and cardboard.

21. Chromogenic Agent for Printing Paper

Acid-activated clays treated with sulfuric acid, hydrochloric acid, or calcium phosphate possess high adsorption and catalytic activity. They are used in fax paper, tax stamps, and pressure-sensitive carbon paper, where they chemically react with colorless dyes to develop visible marks upon contact.

22. Epoxy Modifier for Pulp

Chemically modified bentonite can act as an effective epoxy modifier due to its large surface area and organic intercalation capability. It adsorbs hydrophobic colloidal epoxy in the system, reduces epoxy’s surface energy, and diminishes its viscosity — thus controlling adhesion, agglomeration, and buildup.

23. Papermaking Wastewater Treatment

It is highly effective in treating industrial wastewater from the papermaking industry, thanks to its excellent adsorption and decolorization capabilities. It helps reduce COD (Chemical Oxygen Demand) levels and removes color by adsorbing pollutants from the wastewater.

24. Organic Thickener for Paint

Bentonite has strong water absorption capacity — it can absorb approximately five times its own weight in water and expand to several or even dozens of times its original volume. This expansion produces a colloidal substance that encapsulates pigment particles in paint, preventing them from settling. As an organic thickener, bentonite provides strong thickening effects and floatability, improving paint storage stability and ease of application.

25. Floating Anti-Settling Agent for Paint

Bentonite exhibits excellent floatability and dispersibility in water. It releases charged particles and acts as a wetting agent, enhancing the floatability of water-based paints. Adding a suitable amount of bentonite to architectural coatings prevents settling and layering, ensures color uniformity, and improves the overall suspension stability of the paint.

26. Auxiliary Adhesive for Paint

Thanks to its strong adhesion properties, it can partially replace other raw materials and fillers in architectural paints, reducing production costs while maintaining performance.

27. Rheology Modifier for Coatings

Organic bentonite has outstanding adsorption, swelling capacity, and thixotropy in organic solvents. It is used as a rheological modifier during coating production, application, storage, and film formation, providing structural viscosity at low shear rates.

28. Moisture-Proof Coatings

Bentonite can serve as a raw material for moisture-resistant coatings. Bentonite-emulsified asphalt coatings, made by blending bentonite with asphalt, are ideal for waterproofing roofs. They can increase construction efficiency by 50%, reduce costs by 40%, and significantly improve working conditions and moisture protection.

29. Waterproof Coatings

Bentonite expands upon contact with water. Calcium-based bentonite expands to about 3 times its volume, while sodium-based bentonite absorbs up to 5 times its weight in water and expands 15 – 17 times its original volume. This property makes it useful in producing waterproof materials such as bentonite waterproof blankets and protective layers.

30. Water-Swelling Rubber Waterstop

This type of rubber waterstop uses plastic as a base material, combined with calcium-based bentonite, super absorbent resin, thickening epoxy resin, antioxidants, and other additives. Extruded into shape, the calcium-based bentonite controls the expansion rate of the waterstop, giving it water-swelling and sealing capabilities.

31. Functional Plastic Filler

Through nanotechnology, it can be modified into nano-chemical bentonite and used widely in plastics. It enhances sealing, tensile strength, heat and wear resistance, corrosion resistance, tear strength, and chemical durability of plastic products.

32. Lubricating Grease

Bentonite grease is formulated by thickening mineral oil with activated bentonite. It offers excellent performance across temperature ranges, strong chemical and thermal stability, and good shear resistance. It is commonly used in lubricating chassis parts, universal joints, steering systems, wheels, and centrifugal water pump bearings.

33. Agricultural and Forestry Moisture Retainers

Adding bentonite to water-retaining agents improves the thermal stability and compressive strength of the moisture-absorbing gel. High-bentonite-content composites are suitable for moisture retention in oil and gas field plugging, agriculture, animal husbandry, forestry, and horticulture. Calcium-based bentonite has superior floatability, making it more suitable as a moisturizing material.

34. Fertilizer Carrier

As a fertilizer medium, bentonite improves the safety and convenience of fertilizer application. It also reduces residual distribution in the soil and helps prevent the water pollution caused by the leaching of phenolic compounds from certain fertilizers.

EPIC Powder Machinery is a trusted expert in ultrafine grinding and powder processing solutions. With European core technology and decades of experience, we provide customized, high-efficiency systems that boost productivity and product quality. Partner with EPIC—where precision meets performance.