Silicone sealant is a new type of polymer sealing material. Due to its silicon-oxygen structure and organic groups, it is endowed with excellent UV resistance, high and low temperature resistance, and high humidity resistance.

In addition, silicone sealant has a strong bonding effect on substrates such as metal, glass, ceramics, and plastic. It is widely used in industries such as electronics, lighting, photovoltaics, rail transportation, construction, and more.

Application of Silicone Sealant in the Photovoltaic Industry

Silicone sealant is one of the auxiliary materials used in solar photovoltaic modules, mainly including bonding sealant and potting glue.

Among these, silicone sealant is primarily used in photovoltaic modules to bond solar cells to aluminum alloy frames, junction boxes to back panels, and so on. This is mainly single-component, dealcoholized room-temperature vulcanized silicone rubber. Potting glue, on the other hand, is mainly used for potting components inside junction boxes. Iconsisting of two-component, dealcoholized room-temperature vulcanized silicone rubber. The primary function of both is to prevent water and oxygen in the air from entering the solar photovoltaic cell assembly, thus avoiding a reduction in cell conversion rate due to oxidation of the silicon cells.

The performance of photovoltaic glue is the basis for it to be referred to as “photovoltaic glue.” A series of performance indicators are used to judge the quality of the glue. Studies have shown that the initial bonding shear strength of standard photovoltaic glue should be no less than 1.5 MPa, and the peel strength should be no less than 9.5 kN/m. In terms of aging resistance, it is required that after 1000 hours of aging at 85°C and relative humidity of 85% (the double 85 test). Its various properties (including bonding and mechanical properties) should remain above 75%, and the sealant should meet environmental protection requirements.

Why is Nano Calcium Carbonate Added to Silicone Sealant?

In practical applications, photovoltaic glue is often applied to vertical facades. The sealant is required to be non-drip, non-flowing, and have minimal sag, so it must exhibit good thixotropy. Without this property, it is easy for the adhesive to contaminate the surface of the adhered object or waste glue.

Thixotropy is a rheological phenomenon where the viscosity and shear properties of a dispersion system change over time. The surface of modified nano calcium carbonate is coated with organic substances, significantly improving its compatibility and wettability with organic materials. When applied to silicone glue, nano calcium carbonate helps solve issues like flow, low strength, and poor thixotropy.

Research Progress of Nano Calcium Carbonate Reinforced Photovoltaic Glue

According to public information, the role of nano calcium carbonate in photovoltaic glue is mainly reinforcement and filling.

The reinforcing effect of nano calcium carbonate on photovoltaic glue involves several factors, such as tensile strength, sag, thixotropy, elastic recovery rate, aging resistance, and moisture and heat resistance. Research by Li Fuzhong and others indicates that when the base polymer is 100 parts, and the reinforcing filler, a mixture of nano calcium carbonate and fumed silica in a 10:2 mass ratio, is 100 parts, the crosslinker is 5 parts, and the adhesion promoter (with a mass ratio of aminosilane to alkoxysilane polymer of 2:1) is 1 part, along with 2 parts of tetrabutyl titanate as the catalyst, the comprehensive performance of the sealant is improved. After aging for 1000 hours at 85°C and relative humidity of 85%, its performance retention rate exceeds 90%.

Yu Haixuan et al. disclosed an antioxidant silicone adhesive for solar photovoltaic modules, which includes the following raw materials: 107 silicone rubber, surface-treated nano calcium carbonate, methylphenyl silicone oil, metal oxide, a mixed cross-linking agent, diluent, catalyst, and pre-reaction coupling agent. Experiments have shown that the specially surface-treated nano calcium carbonate enhances the strength and toughness of the adhesive.

Hangzhou Zhijiang New Materials Co., Ltd. offers a dealcohol-type silicone rubber sealant containing 100 parts by weight of polydimethylsiloxane. Also other sealant like 20 to 200 parts by weight of calcium carbonate, 2 to 12 parts by weight of organic silicon cross-linking agent, etc. The sealant prepared with this formula exhibits good adhesion to metals, plastics, ceramics, glass, and other materials. It’s suitable for use in sealing photovoltaic modules, buildings, automobiles, and electronic appliances.

Some Domestic Nano Calcium Production Enterprises for Photovoltaic Glue

Notable domestic nano calcium production companies for photovoltaic glue include: Guangxi Warner New Materials Co., Ltd. Hubei Kailong Chemical Group Co., Ltd. Cairns Nano Materials Co., Ltd. Shandong Yuxin Nano Technology Co., Ltd.

Conclusion

In the past two years, the photovoltaic industry has experienced rapid growth, and the industrial chain market has generally benefited.

Currently, China’s adhesive market is developing rapidly. The number and scale of nano calcium production enterprises for photovoltaic glue also increasing. It is important to note that the production technology of silicone sealants for photovoltaics is continually evolving, and the application and demand for nano calcium carbonate are likewise dynamic and growing.

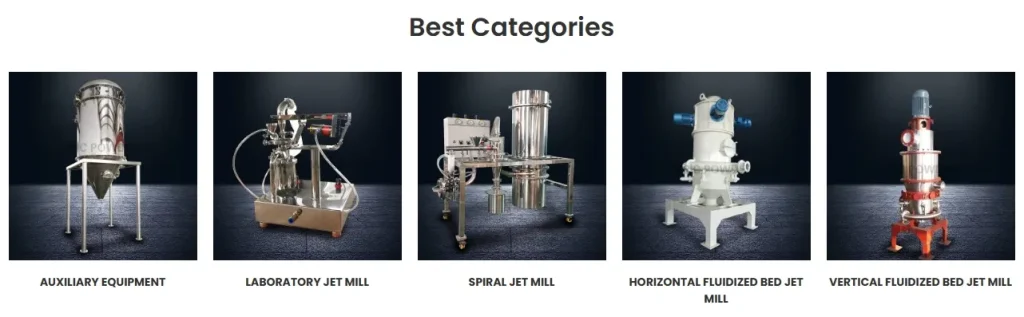

Epic Powder

At Epic Powder Machinery, we are dedicated to advancing the technology of ultrafine grinding and material processing. Our state-of-the-art equipment ensures high precision in particle size distribution and material properties, supporting industries such as photovoltaics. Whether for improving the performance of silicone sealants or other applications, Epic Powder provides innovative solutions to meet the evolving needs of the market.