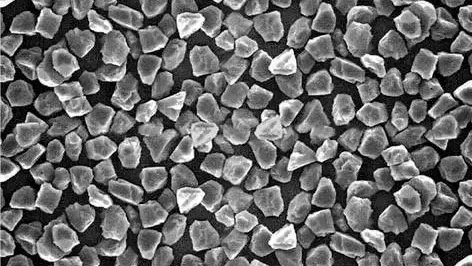

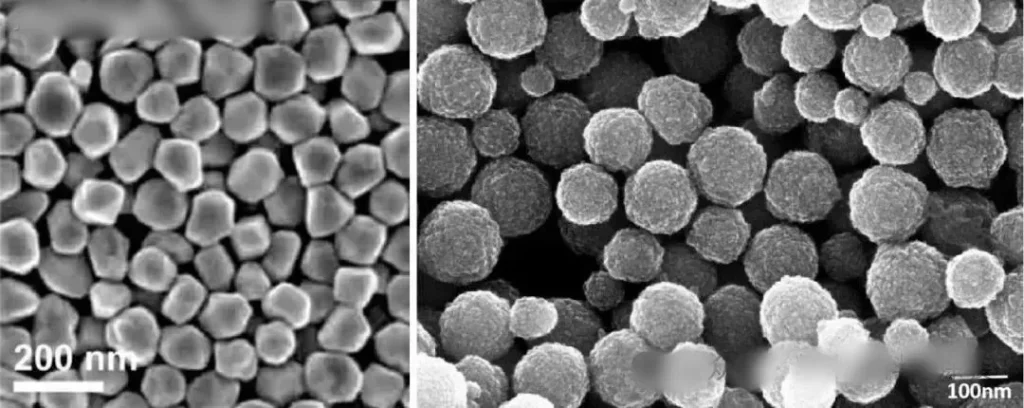

In materials science and particle analysis, particle size is referred to as “grain size,” also called “granularity” or “diameter.” For non-spherical particles, size measurement depends on the reference method and statistical approach. So only “equivalent particle size” can be used.

When a particle’s physical property or behavior closely matches that of a sphere (or group of spheres) of a certain diameter, that sphere’s size (or combined size) is assigned as the particle’s equivalent diameter (or size distribution). The percentage (or cumulative percentage) of particles within specific size ranges relative to the total powder mass defines the frequency distribution (or cumulative distribution).

The vertical axis represents size composition calculated using different bases. It can be expressed as percentage/cumulative percentage by: particle count, length, surface area, volume. The horizontal axis shows size values calculated using different measurement bases.

Among these, D10, D50 and D90 serve as critical indicators of powder uniformity and are collectively known as the cumulative distribution parameters.

Particle Size Distribution Parameters: D10, D50, D90 Explained

– D50: Also known as the median particle size. It refers to the size value corresponding to 50% cumulative distribution percentage. This value precisely divides the entire particle population into two equal parts. 50% of particles are larger than this value, while the other 50% are smaller. For example, if a sample has D50 = 5μm, it means that among all particles constituting the sample. Half of them are larger than 5μm and half are smaller. It is commonly used to characterize the average particle size of powders.

– D90: Represents the particle size value corresponding to 90% cumulative distribution percentage when particles are accumulated from smallest to largest. In other words, in a given powder, particles smaller than D90 account for 90% of the total particle count. It’s typically used to measure the coarse-end size index and serves as a crucial indicator in powder production and applications. Similarly, some industries also use D95 and D97 values, whose physical meanings are essentially the same as D90.

– D10: This value indicates that 10% of particles have sizes below this diameter, representing the opposite concept of D90.

In practical production and daily applications, these three parameters (D10, D50, D90) hold significant importance. Taking the pharmaceutical industry as an example, understanding the particle size distribution of a drug helps determine its efficacy and potential side effects. In environmental protection, size distribution serves as an important measurement indicator for air and water quality monitoring.

Microscopic particulate matter finds wide applications in both daily life and industrial production. Their size and distribution directly affect industrial processes, product quality, energy consumption, and production safety. Therefore, developing accurate and convenient measurement methods for microscopic particle diameter (particle size) and obtaining precise particle size distribution functions carries extremely important practical significance.

At Epic Powder Machinery, we specialize in cutting-edge particle size analysis and powder processing equipment designed to deliver precise D10, D50, and D90 measurements for industries ranging from pharmaceuticals to environmental monitoring. Our advanced technology ensures accurate, repeatable results—helping you optimize product quality, enhance process efficiency, and meet stringent regulatory standards.