Limestone and chalk are essential minerals widely used in various industries such as construction, agriculture, and even cosmetics. Understanding their formation, properties, and processing methods is crucial for maximizing their potential in industrial applications. This article explores the geological origins and characteristics of limestone and chalk, while also highlighting how Epic Powder Machinery’s jet mills and air classifier mills can optimize the processing of these minerals to meet industry-specific demands.

Limestone and chalk belong to base rocks, including dolomite, while marble and calcite are derivatives.

Chalk

Chalk is loose in texture and has a certain degree of stickiness. Its crystals are likely microcrystalline, and it has a high grade, meaning it contains a higher amount of calcium. In simpler terms, it is rich in calcium. The debris particles that settle in the washing water of marble also have a similar appearance. Loose, mud-like chalk is often found on the base rocks surrounding marble.

The closer it is to the marble, the denser it becomes, and even white calcite particles may appear in the middle. However, due to weathering, water solubility, or leaching, chalk on the outer edges rarely exists in large mineral deposits and is often found in the form of a thin crust, which is often overlooked.

Limestone

Limestone, commonly known as limestone, is dense and also belongs to microcrystalline minerals. It contains more impurities and has a lower calcium content. Due to its relatively stable compactness, it is frequently found surrounding marble or calcite deposits.

Marble

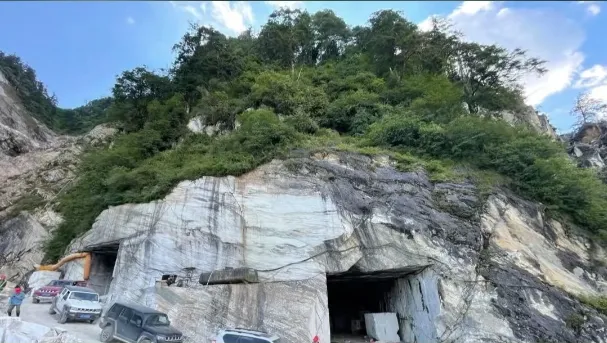

Marble is a metamorphic rock that can be formed from the metamorphism of chalk or limestone. Therefore, unaltered base rocks are often found surrounding it. For instance, a mining report from a mine in Xinjiang showed that thermal contact metamorphism formed ore veins, which consist of limestone, dolomite, and other base rocks, as well as slightly metamorphosed microcrystalline marble and base rock mixtures, and strongly metamorphosed coarse-grained marble. In thermal contact zones, very coarse rhombohedral crystals, known as “large calcite,” may even form.

Upon careful observation, it is often found that limestone, when metamorphosed, results in darker colors or large grade variations. Chalk metamorphism results in lighter colors or higher grades. For example, metamorphosed marble in the asbestos zone generally has a higher whiteness, while metamorphosed marble in the Shiyan region has a medium level of whiteness.

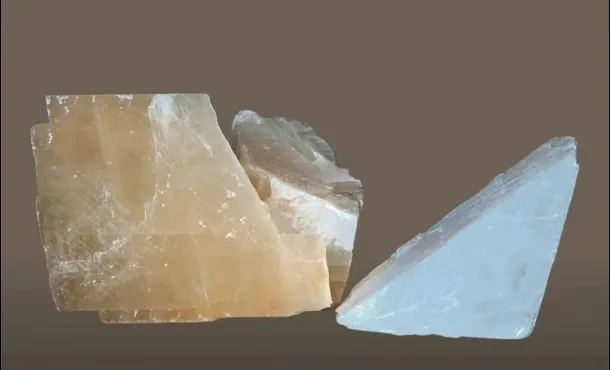

Calcite

Hydrothermal filling of calcite often occurs in areas with surrounding limestone, dolomite, or other base rocks. These deposits are usually located along fault zones, such as in a mine in Hubei. The calcium bicarbonate in the hydrothermal fluid comes from the surrounding limestone or dolomite and could also originate from dissolved chalk ore. Fault zones and surface water erosion tend to create karst landforms. Typically, the boundary between hydrothermal filling calcite ores and the surrounding metamorphosed marble is distinct. Whether this is due to high-temperature, high-pressure, oversaturated steam with higher solubility remains unclear. The crystal structure of hydrothermally filled calcite ores depends on the filling conditions, and along the cracks, the crystals appear rod-shaped. Smaller rhombohedral structures may also appear due to cleavage. When filling caves, they form crystal cavities.

Similarly, large rhombohedral calcite crystals in hydrothermal deposits tend to have higher grades. The entire mineral zone is relatively uniform with a milky white color. However, rhombohedral calcite formed in contact metamorphosed marble can only form at the thermal contact sites. Its grade and uniformity depend on the surrounding base rock.

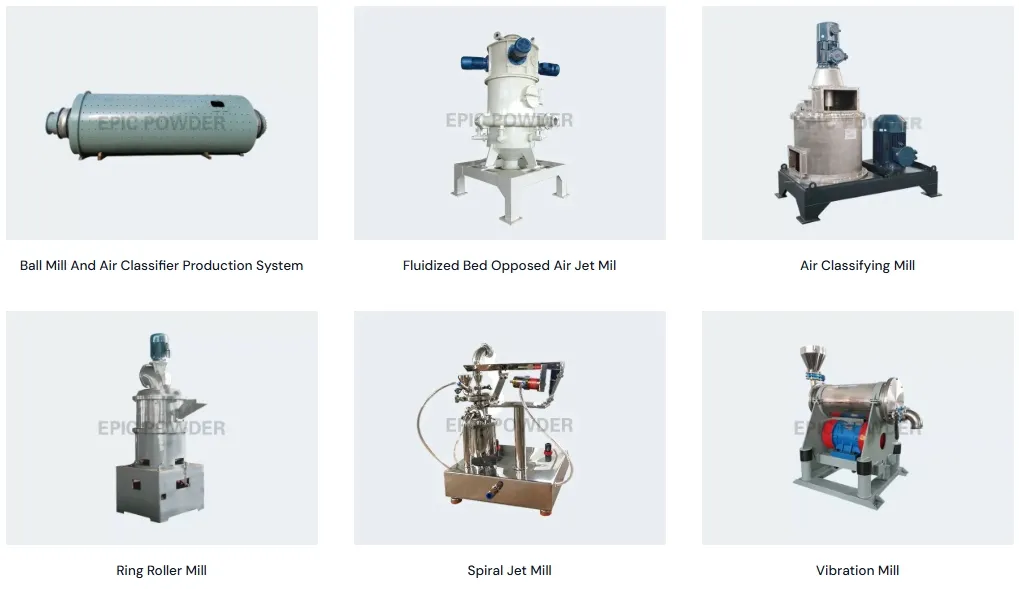

Processing with Epic Powder Machinery

Epic Powder Machinery, a leading provider of advanced ultrafine grinding solutions, plays a crucial role in processing minerals such as limestone, chalk, and marble to meet specific industry needs. Our jet mills and air classifier mills are ideal for breaking down these minerals into ultrafine powders with precise particle size distribution.

Epic Powder’s jet mills are highly effective in handling heat-sensitive materials and can achieve fine grinding without introducing excessive heat, ensuring that the minerals retain their chemical integrity. Additionally, the air classifier mills are perfect for classifying powders based on their particle size. These systems ensure the precise separation of fine and coarse particles, which is essential for producing uniform powder products.

Whether it’s the processing of limestone for construction use, chalk for industrial applications, or fine marble powder for cosmetic formulations, our equipment ensures high efficiency, low energy consumption, and superior particle size control.

By integrating our air classification and jet milling technologies, we provide tailored solutions that optimize the grinding and classification processes, enhancing product quality and consistency.

This understanding comes from reviewing mining exploration reports and field observations of mineral deposits. With Epic Powder Machinery, we ensure that your mineral processing operations are smooth and efficient, delivering high-quality end products to meet your business needs.