In the plastics industry, Polypropylene (PP) is renowned for its cost-effectiveness. However, its shortcomings—being soft, prone to deformation, and having poor heat resistance, often pose challenges for manufacturers. Talc powder, when precision-processed by advanced moinho de jato technology, is far more than just a filler. It’s a performance-enhancing assistant that precisely addresses PP’s weaknesses. The jet milling process ensures the talc particles achieve optimal morphology and particle size distribution. It is crucial for maximizing performance.

1. Significantly Enhances Mechanical Properties of PP

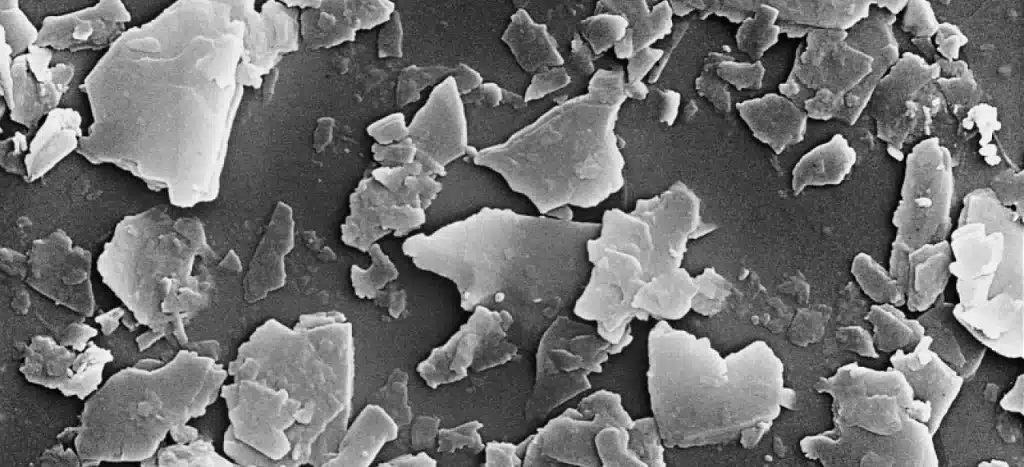

A major drawback of PP is its lack of rigidity at room temperature, making it susceptible to bending and deformation under stress. Talc powder directly reinforces PP. The effectiveness of talc is heavily dependent on its particle size and structure. Moinho de jato processing plays a vital role here, as it can produce talc with a controlled, narrow particle size distribution and preserve its beneficial lamellar (plate-like) structure.

Upgraded Stiffness & Hardness: The layered structure of talc powder, optimally dispersed thanks to the fine and consistent particle size achieved through fresagem a jato, supports polymer chains like a skeleton within the PP matrix. This can increase the flexural modulus (a key indicator of rigidity) of PP by 30%-80%, with a notable improvement in hardness.

Improved Wear & Impact Resistance: The filled PP surface becomes denser. Furthermore, the fine, uniform talc particles produced by a moinho de jato can contribute to better interfacial adhesion with the PP polymer chains, which helps in reducing the friction coefficient and enhancing wear resistance.

2. Optimizes PP Heat Resistance & Processability

PP has a relatively low Heat Deflection Temperature (HDT), typically around 60-80°C, causing it to soften easily at high temperatures. Talc powder effectively addresses this issue.

Markedly Improved Heat Resistance: Talc powder itself has a high melting point (approx. 1500°C). The high-purity talc powder, often obtained after processing through an air classifier mill (a key component in modern fresagem a jato systems), can more effectively inhibit molecular chain movement in PP at elevated temperatures.

3. Cost Reduction Without Performance Loss: Maximizing Value

For businesses, “cost reduction” is a perpetual goal, and talc powder excels as a “value-for-money solution” in this regard.

Performance-Preserving Filling: Unlike some other low-cost fillers, high-quality talc does not significantly weaken the toughness and strength of PP. The consistent quality of talc, ensured by efficient jet mill grinding, is key to achieving the dual goals of cost reduction and quality improvement.

4. Improves Aesthetic Appeal

PP products often suffer from uneven surface gloss and susceptibility to sink marks, affecting their appearance. Talc powder helps enhance the look of PP.

Smoother, More Refined Surface: The fine and consistent particle size of talc, a direct result of effective jet mill processing, allows it to fill micro-indentations on the PP surface more effectively, resulting in a smoother finish.

5. Enhances Dimensional Stability: Reduces Deformation, Improves Precision

PP products are prone to dimensional shrinkage or expansion due to changes in ambient temperature and humidity during storage or use. Talc powder helps “lock in” the dimensional stability of PP.

Reduced Post-Molding Shrinkage: Talc powder inhibits both the crystallization shrinkage and thermal shrinkage of PP. The uniform dispersion of fine talc particles, facilitated by the optimal particle size achieved through fresagem a jato, is crucial for achieving consistent and reduced shrinkage across the entire part.

6. Expands Application Horizons: Opening New Markets for PP

Precisely because of the performance enhancements high-quality talc powder brings, PP can now more easily enter application areas previously limited by its weaknesses.

Automotive & Aerospace Sector: From interior parts to under-the-hood components, talc-filled PP is gradually replacing metals and other engineering plastics. The reliability of these high-performance composites starts with raw material consistency, which is why many advanced material producers insist on talc processed using fluid energy mill (another term for moinho de jato) technology to ensure batch-to-batch uniformity.

Choosing the Right Talc Powder is Key to Maximizing Performance

Of course, to achieve the optimal effect from talc powder in PP, companies must pay attention to selection. It is crucial to source talc from suppliers who utilize advanced processing technologies like jet mills. Jet mill systems, often integrated with high-precision air classifiers, are essential for producing the consistent particle size and high purity required for high-performance PP compounds. This technology helps avoid agglomeration and ensures strong interfacial adhesion between the talc and the polymer matrix.

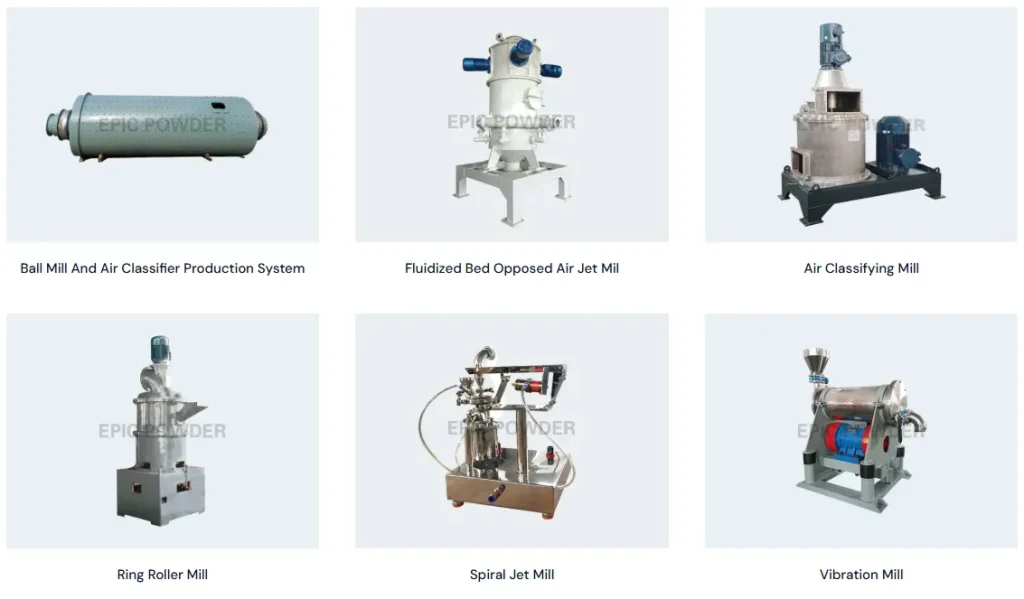

Partner with Epic Powder Machinery for Superior Performance

To fully unlock the potential of talc powder in your PP applications, the quality and consistency of the powder itself are paramount. Maquinário de Pó Épico specializes in the design and manufacturing of high-performance moinhos de jato and integrated grinding systems. Our advanced fluidized bed jet mills e moinhos classificadores de ar are engineered to deliver precisely controlled particle size distribution, high purity, and preserved particle morphology for talc and a wide range of other mineral fillers. By partnering with Epic, you gain access to the technology that empowers you to produce superior talc-filled PP composites with enhanced mechanical properties, thermal stability, and aesthetic quality. Let Epic Powder Machinery be your trusted partner in achieving excellence in material science and manufacturing.

Maquinário de Pó Épico

Maquinário de Pó Épico is a leading innovator in powder processing technology. We provide comprehensive solutions for fine grinding, precise classificação, and surface modification. Our commitment to research and development ensures that our clients have access to the most efficient and reliable equipment. If you’re interested in our machines, please feel free to contact us for a tailored solution.