NO. 369, Road S209, Huanxiu, Qingdao City, China

Jet Mill,Fluidized Bed Jet Mill,EPIC Powder Machinery

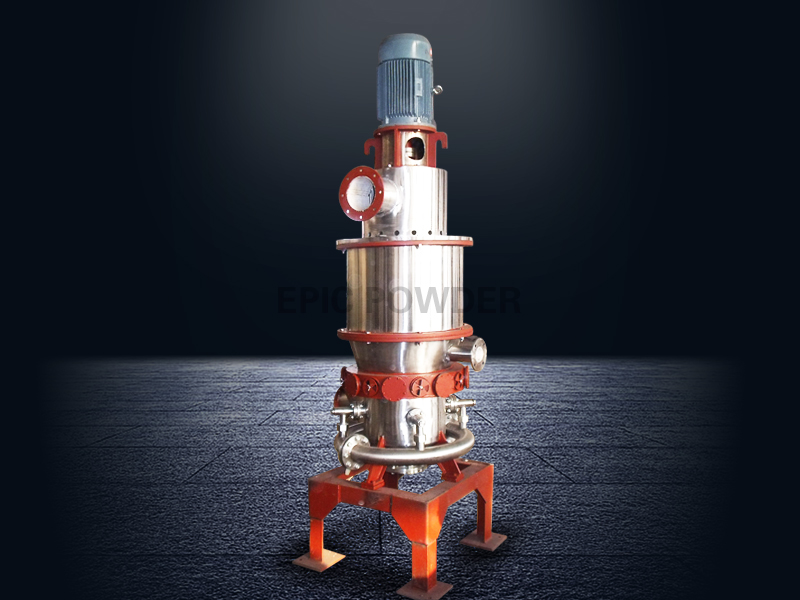

Jet Mill MQL

Product Description

Jet mill consisting of fluid bed opposed jet mill with integrated turbo classifier(s) for highest applications with best top cut and steep particle size distribution. The classifier rotor is vertically installed.

There are various functions as mainly:

grinding

classifying

homogenization and mixing

selective operation

drying

surface treatment

and many others

Product Feature

Fluid bed opposed jet principle

Integrated turbo classifier as single wheel or multi-wheel

Products free of oversize

Steep particle size distribution

Multifunction

Special nozzle configuration

Los in weight system

Laboratory system available

Cryogenic, inert, hot gas solutions

Principle

After the compressed air is filtered and dried, it is sprayed into the grinding chamber at high speed through the Laval nozzle. At the intersection of multiple high-pressure air flows, the materials are repeatedly collided, rubbed, and sheared to be crushed. The crushed materials rise with the suction of the fan. The airflow moves to the classification zone. Under the action of the strong centrifugal force generated by the high-speed rotating classification turbine, the coarse and fine materials are separated. The fine particles that meet the particle size requirements enter the cyclone separator and dust collector through the classification wheel for collection, and the coarse particles descend to the crushing zone and continue to be crushed.

Product Parameter

| Model | MQL03 | MQL06 | MQL10 | MQL20 | MQL40 | MQL60 | MQL80 |

| Feed Size mm |

<3 | <3 | <3 | <3 | <3 | <3 | <3 |

| Product Fineness d97:um |

8- 150 | 8- 150 | 8- 150 | 8- 150 | 10- 150 | 10- 150 | 10- 150 |

| Output kg/h |

5- 100 | 10- 200 | 20- 400 | 50- 800 | 150- 1500 | 300- 2000 | 400- 6000 |

| Air Consumption m3/min |

3 | 6 | 10 | 20 | 40 | 60 | 80 |

| Air Pressure MPA |

0.6 - 0.85 | 0.6 - 0.85 | 0.6 - 0.85 | 0.6 - 0.85 | 0.6 - 0.85 | 0.6 - 0.85 | 0.6 - 0.85 |

| Installation Power KW |

26- 37 | 47- 68 | 68- 106 | 145- 184 | 276- 310 | 402- 427 | 520- 600 |

Note:

Data of production capacity and product fineness in this sheet are just for your reference. Different materials have different characteristics, and then one model of jet mill will give different production performance for different material. Please contact me for tailored technical proposal or trials with your material.

Our Commitment

We are committed to realizing service modernization and technology optimization, using technology to solve customer problems, and using service to improve customer experience.

-

Combination of production and research

-

Non-standard customization

-

One-stop service

-

Technical support and optimization