Enhancing the compaction density of lithium iron phosphate (LFP) is crucial for improving the volumetric energy density of batteries. Doping with elements like Ti or Al and employing secondary sintering (also known as “second firing”) are two highly effective but fundamentally different technical approaches. Below, we explain each method in detail.

The jet milling process at Epic Powder is a closed-loop, dry mechanical method that guarantees no contamination. Through this process, we can achieve hard carbon powders with a controlled particle size distribution from 3 to 45 microns. This versatility allows it to serve markets like plastic fillers, rubber reinforcement, and water purification filters.

Approach 1: Ion Doping (e.g., Ti⁴⁺, Al³⁺)

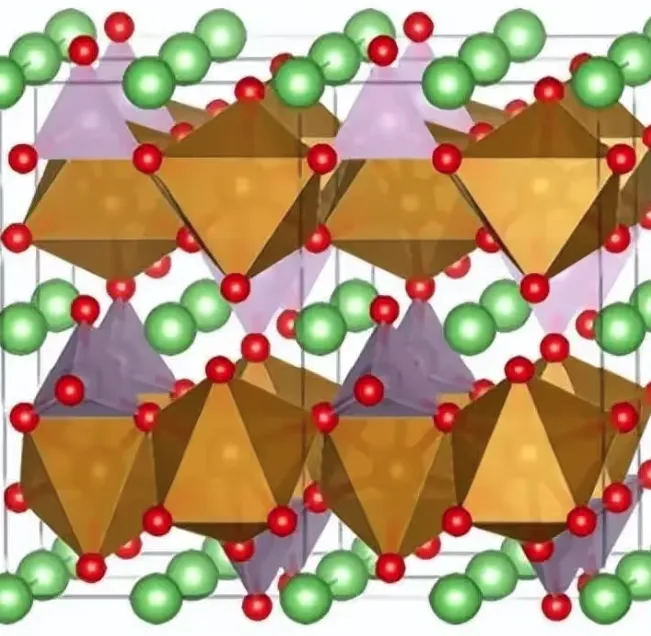

Ion doping modifies the intrinsic properties of the material at the atomic scale to improve its processing performance.

1. Core Purpose of Doping: Enhancing Intrinsic Electronic Conductivity

• The Problem: Pure LFP is a semiconductor with extremely low electronic conductivity (~10⁻⁹ S/cm). This makes electron transport within and between particles challenging during charge-discharge cycles.

• Role of Doping: By partially substituting Li⁺ or Fe²⁺ sites with high-valence cations (e.g., Ti⁴⁺), charge balance in the crystal lattice is maintained by generating Fe³⁺ ions. The coexistence of Fe²⁺ and Fe³⁺ enables rapid electron hopping via a “small polaron hopping” mechanism, significantly boosting the material’s intrinsic electronic conductivity (by several orders of magnitude).

2. How Electronic Conductivity Affects Compaction Density

• Root Cause: During electrode preparation, roller pressing deforms and compacts powder particles to increase contact. For undoped LFP, poor conductivity means that overly dense pressing increases contact points but also interfacial resistance, as each contact point has high resistance. This leads to poor lithium-ion reaction at the electrolyte/solid particle interface, increasing polarization and drastically reducing battery capacity. Consequently, undoped LFP has a pressing limit, restricting its compaction density.

• Doped LFP: With significantly improved particle conductivity, densely pressed particles form good ohmic contacts, allowing smooth electron flow without severe interfacial polarization. This enables higher pressing pressures, achieving greater compaction density without sacrificing electrochemical performance.

Doping transforms insulating cotton (undoped LFP) into elastic, conductive rubber balls (doped LFP). You can press the rubber balls tightly, and their large contact area remains conductive. However, pressing cotton too hard turns it into an airtight, insulating board.

Approach 2: Secondary Sintering (Second Firing)

Secondary sintering optimizes the physical morphology and particle size distribution at a macroscopic scale.

1. Typical Process of Secondary Sintering

• First Firing: Completes the basic solid-phase reaction to synthesize LFP, but the resulting primary particles may be small, irregularly shaped, defective, or have uneven carbon coating.

• Crushing/Grinding: Breaks down agglomerated blocks from the first firing into finer, more uniform powders.

• Second Firing: Re-sinters the crushed powder at an appropriate temperature.

2. How Secondary Sintering Improves Compaction Density

• Promotes Particle Growth and Spheroidization: During secondary sintering, surface diffusion and atomic migration cause small, irregular particles to grow larger and become more regular, approaching spherical or cubic shapes. Spherical particles have optimal flowability and packing efficiency, enabling the tightest packing during roller pressing.

• Optimizes Particle Size Distribution: Controlled processes yield a balanced “large particle + small particle” distribution. During pressing, small particles fill gaps between larger ones, much like fine sand filling spaces between pebbles, significantly increasing packing density (i.e., compaction density).

• Improves Carbon Coating and Crystallinity: Secondary sintering ensures a more uniform and complete carbon coating while repairing crystal defects from the first firing, making particles more robust and less prone to fracturing under high pressure.

Secondary sintering is like processing a pile of uneven, mixed-sized gravel (first-fired material). First, it’s crushed into smaller particles. Then, through the “annealing” of secondary sintering, these particles grow into uniformly sized, smooth pebbles. These “pebbles” stack much more densely than chaotic “gravel.”

Summary and Comparison

| 특징 | Ion Doping (Ti, Al, etc.) | Secondary Sintering (Second Firing) |

| Scale of Action | Atomic/Electronic Scale | Particle/Morphology Scale |

| Core Principle | Enhances intrinsic electronic conductivity, allowing higher pressing pressures without severe polarization. | Optimizes particle morphology (spheroidization) and size distribution to improve packing efficiency. |

| Main Effect | Overcomes compaction xsddensity limits caused by poor conductivity. | Naturally increases compaction density by improving physical packing. |

| Process Characteristics | Achieved during first sintering; a chemical modification. | Requires additional crushing and sintering steps; a physical/process modification. |

| Cost | Involves doping agent costs but no additional process steps. | Increases energy and time costs, significantly raising production costs. |

In high-end LFP production, these two techniques are often combined: ion doping enhances intrinsic conductivity, while secondary sintering optimizes particle morphology. This synergy produces LFP cathode materials with both excellent electrochemical performance and ultra-high compaction density (up to 2.6 g/cm³ or more).

에픽 파우더 머시너리

~에 에픽 파우더 머시너리, we specialize in advanced powder processing solutions, including state-of-the-art jet mills designed for producing high-performance lithium iron phosphate (LFP). Our jet mills ensure precise particle size control and uniform morphology, enabling the production of LFP with superior compaction density and electrochemical properties. As a leading provider of powder processing equipment, we are committed to delivering tailored solutions to meet your specific needs. Contact us today via WhatsApp: +86 157 6227 2120 for a customized solution that drives your success in battery material production.