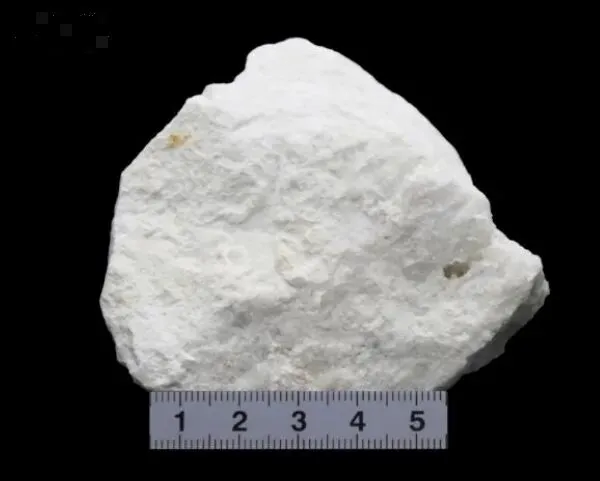

Quartzite is a metamorphic rock composed mainly of quartz. It is far from ordinary—instead, it serves as a critical mineral resource supporting numerous industrial sectors. It forms through the regional metamorphic recrystallization or contact metamorphism of protoliths such as quartz sandstone, other siliceous rocks, or silica-rich rocks near magmatic bodies. Quartzite ore consists of cryptocrystalline quartz and possesses a distinct granular crystalline texture with crystalline aggregates. Its main component, quartz (SiO₂), accounts for over 85% of its composition, providing a solid foundation for its industrial applications.

Quartzite deposits offer significant industrial advantages. They are not only large in scale but also geologically stable with favorable mining conditions, making them highly suitable for large-scale industrial production. However, quartzite also has notable limitations: it is generally very hard, and purifying it from impurities is challenging. As a result, it is typically not used in the production of mid-to-high-purity quartz sand. Instead, quartzite is primarily applied on a large scale in fields where high quartz purity is not required, such as glass sand, 3D printing sand, and raw materials for metallic silicon.

In terms of resource distribution, China is rich in quartzite mineral resources, with as many as 399 mining areas. The distribution of quartzite deposits varies based on their intended use. Among them, there are 242 quartzite deposits for glass production, mainly concentrated in Liaoning, Anhui, Jiangxi, Shandong, and Fujian. Some larger mining areas are also found in Qinghai, though their numbers are relatively small. There are 155 quartzite deposits for metallurgical purposes, primarily located in Beijing, Ningxia, Qinghai, Gansu, Shaanxi, Inner Mongolia, and Liaoning.

Occurrence of Impurities in Quartzite Ore

Impurities in quartzite ore can be divided into three main types: associated gangue minerals, inclusion impurities, and crystal defects and impurities. Different types of impurities have varying impacts on the industrial value of quartzite.

Associated Gangue Minerals

The associated gangue minerals in metamorphic quartzite ore generally depend on the metamorphic conditions. Minerals such as chlorite, muscovite, sericite, or amphibole are more common in low-grade metamorphic rocks, while kyanite, staurolite, or garnet are found in high-grade regional metamorphic rocks. Quartzites of different metamorphic origins also typically contain different gangue minerals. During beneficiation and purification, targeted processes and methods must be selected based on the characteristics of the ore.

Inclusion Impurities

Inclusion impurities can be further classified into mineral inclusions, melt inclusions, and fluid inclusions. Mineral inclusions typically form alongside quartz crystals, meaning gangue minerals are enclosed within the quartz crystals. The type and quantity of mineral inclusions generally have a significant impact on the trace element composition of quartz. Separating common mineral inclusions in quartz, such as feldspar, hematite/limonite, mica, kaolinite, calcite, tourmaline, rutile, and zircon, is quite challenging.

Melt inclusions usually consist of molten silicate minerals from ore-forming fluids or hydrothermal solutions. These molten silicate minerals fail to separate from the silica fluid before quartz crystallization, becoming trapped in silicon-rich fluids or hydrothermal solutions. Fluid inclusions are generally categorized into gas, liquid, and gas-liquid two-phase inclusions. In industrial quartz raw materials, fluid inclusions often affect the chemical composition and quality of the quartz feedstock, influencing its melting properties. However, in quartzite formed by metamorphism, the number of fluid inclusions is generally low, and they are usually not a major concern in mid-to-low-grade quartz sand applications.

Crystal Defect Impurities

Some industrial applications require very high purity in quartz raw materials, making lattice impurities in quartz ore a critical factor. Quartz lattice impurities occur due to atomic substitutions during mineralization or local imbalances in the silicon-to-oxygen ratio, leading to crystal defects during crystallization. Crystal defects in quartz are generally related to the intrusion of heterogeneous atoms (such as Al, Ti, Ge, Fe, H, Ag, Cu, P) into lattice or interstitial sites, as well as Si or O vacancies.

Based on these characteristics, they are typically classified into intrinsic defect centers and extrinsic defect centers. In quartz ore, aluminum (Al) is one of the most common lattice impurities. In lower-quality quartz ore, Al content can reach over 1000 μg/g. For the production of high-purity quartz sand, which demands extremely high quality, lattice impurities cannot be overlooked. However, for ordinary glass sand or quartz sand used in photovoltaic glass, lattice impurities are generally not a major concern.

Core Industrial Applications of Quartzite

Thanks to its unique physical and chemical properties, quartzite plays an irreplaceable role in multiple industrial sectors, with the glass and metallurgy industries being its core application fields.

Quartzite for Glass

The glass industry is the largest consumer of quartz resources. Quartz is widely used in construction, automotive, new energy, and other fields. Major glass products include flat glass, container glass, tempered glass, photovoltaic glass, and electronic glass.

In China, the quartz resources used for manufacturing conventional glass products such as flat glass and tempered glass have relatively low requirements. These can be sourced from large-scale, easily mined, and processed quartzite resources. In contrast, quartz sand for low-iron ultra-clear glass, such as photovoltaic glass, requires slightly higher purity and other indicators. This can be obtained through deep processing of high-quality quartzite resources.

Photovoltaic ultra-clear glass has higher transparency than ordinary glass, making iron content a critical factor. TiO₂ can enhance ultraviolet absorption, reduce UV and visible light transmittance, and interact with Fe³⁺ impurities, causing intense coloration and affecting the performance of photovoltaic ultra-clear glass. Therefore, when producing photovoltaic ultra-clear glass, it is particularly important to select quartzite raw ore with low TiO₂ and Fe₂O₃ impurities and to reduce the reduction of iron oxide in the quartzite raw material.

Quartzite for Metallurgy

In the metallurgical field, quartzite is equally indispensable. It is the main source of silicon in industrial silicon production. However, in actual production, due to differences in the origin and formation of quartzite, even quartzite with similar chemical compositions may vary in physical and chemical properties such as melting point, thermal stability, and explosion resistance. The structure and density of quartzite also affect its melting and reduction properties, ultimately influencing furnace conditions and the quality of industrial silicon.

During industrial silicon smelting, the crystal phase transformation process of quartz varies, leading to different structural changes. Given the high temperatures involved in industrial silicon smelting, using unsuitable quartz raw materials can result in poor reactivity and permeability of the furnace charge. This ultimately reduces the recovery rate of silicon, increases production costs, and worsens performance indicators. Therefore, when selecting quartzite mining sites, it is necessary not only to conduct chemical composition analysis of the raw ore but also to perform essential physical and chemical tests.

Additionally, quartzite for metallurgy is one of the main raw materials for ferrosilicon smelting. Its SiO₂ content must be greater than 97%. The lower the SiO₂ content, the higher the temperature required during smelting. Furthermore, the quartzite raw material must possess good thermogravimetric and heat capacity characteristics, enabling efficient formation of silicon carbide with carbonaceous reducing agents while minimizing weight loss. Otherwise, more reducing agents and electricity will be consumed, reducing the recovery rate of elements.

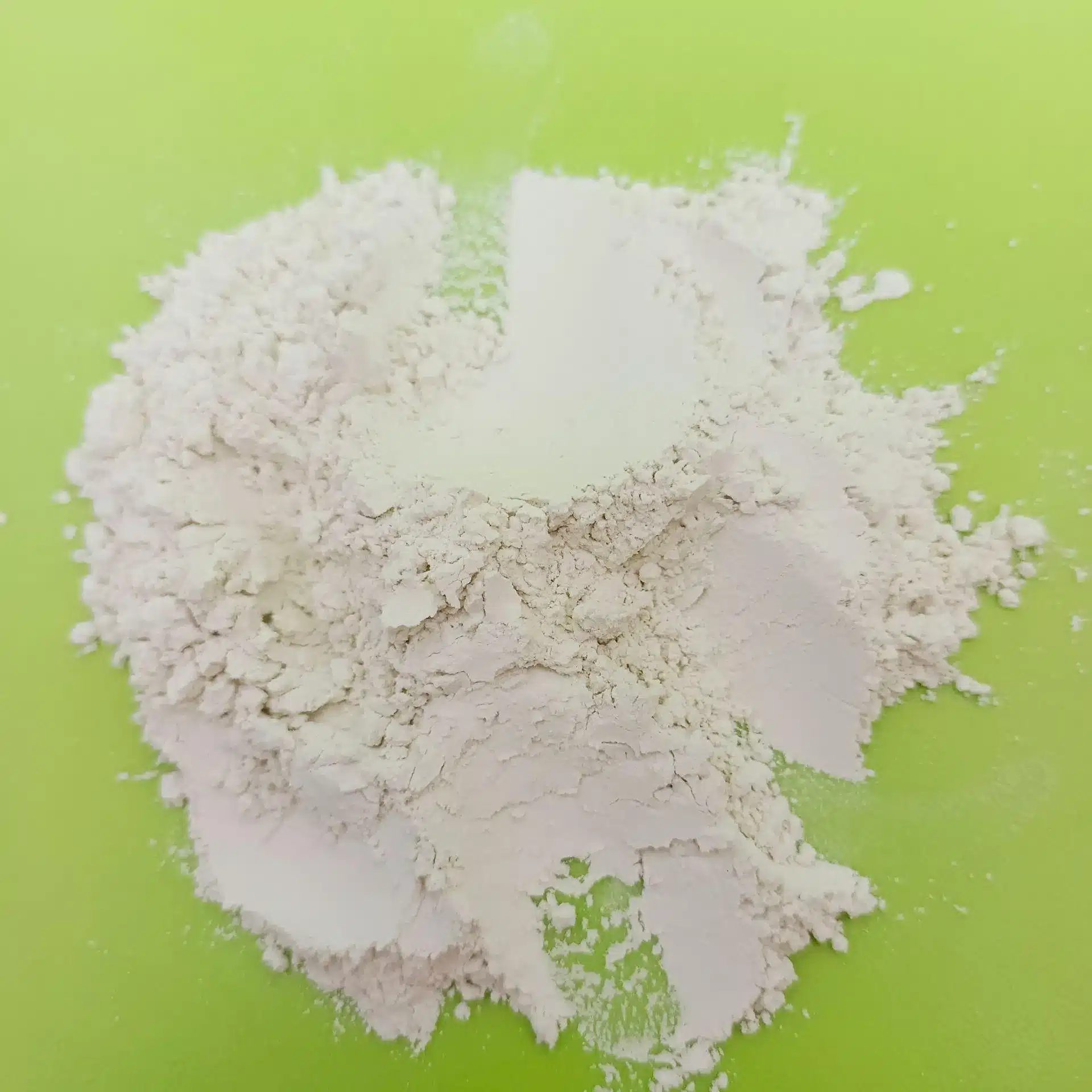

Эпический порошок

The Epic Powder Air classifier Mill stands out as the ideal choice for high-demand quartz powder processing, offering exceptional grinding efficiency and precise particle size control. Whether it’s kaolin, chemical materials, or specialty powders, Epic Powder delivers efficient, energy-saving, and environmentally friendly solutions.

Contact us today for a customized solution and experience industry-leading powder processing technology.