As the global energy landscape rapidly shifts toward electrification and renewable storage, the battery materials sector is experiencing unprecedented growth and innovation. EPIC Powder Machinery stands at the forefront of supplying advanced ultrafine grinding solutions. Our jet pulverizers are designed to meet the strict requirements of battery material production particularly. This article, aimed at technical professionals and equipment suppliers, explores the main types of battery materials, critical jet pulverizers considerations, and provides detailed industry data and analysis to offer a comprehensive perspective on this dynamic field.

1. Overview of Key Battery Materials

Battery technologies rely on a suite of carefully engineered materials, chiefly categorized into:

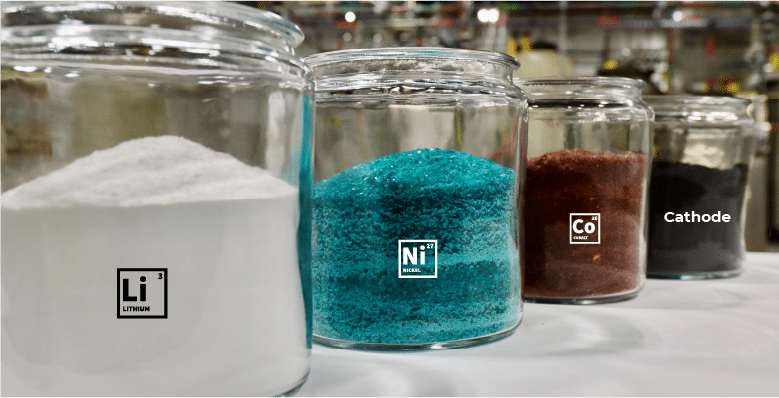

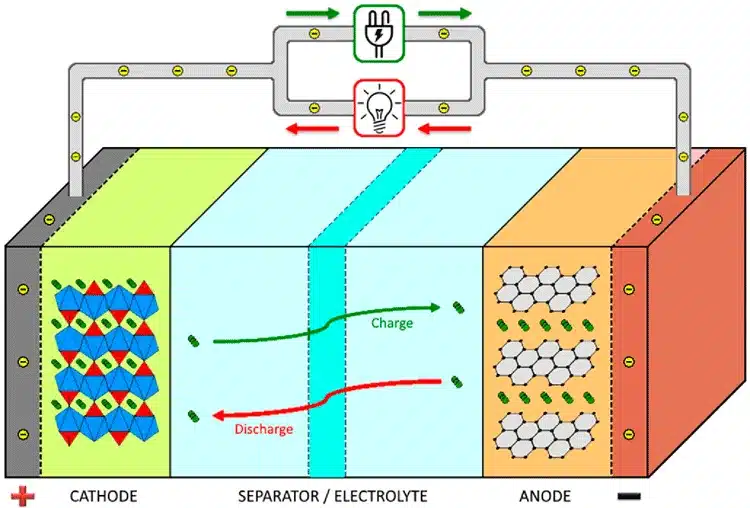

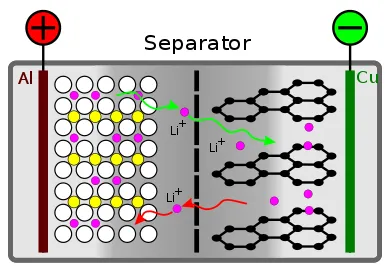

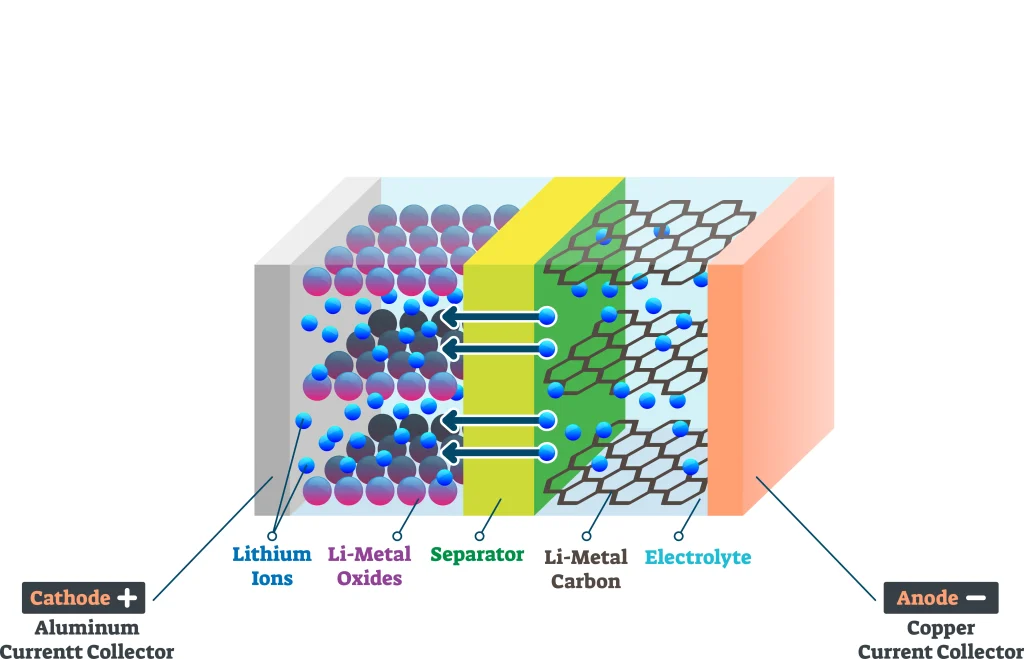

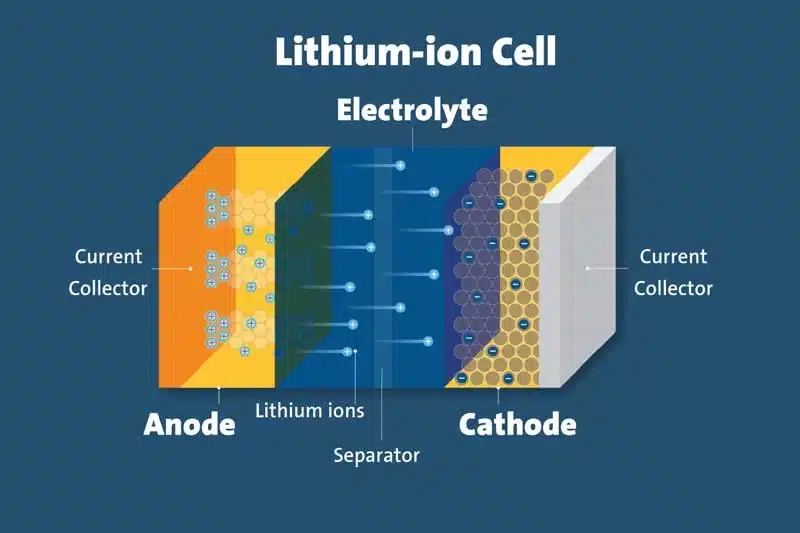

• Cathode Materials: Predominantly lithium-based compounds such as Lithium Nickel Manganese Cobalt Oxide (NMC), Lithium Iron Phosphate (LFP), and Lithium Cobalt Oxide (LCO). These materials determine energy density and stability.

• Anode Materials: Mostly graphite (natural or synthetic) and emerging silicon-based composites, crucial for electron flow and charge capacity.

• Electrolytes and Separators: Although not powders, their compatibility with milled materials influences overall battery performance.

Currently, lithium-ion batteries dominate the market, commanding an estimated 53% share in 2025, attributable to their superior energy density, rapid charging, and cycle durability.

2. The Role of Jet Pulverizers in Battery Material Production

Jet pulverizers are central to producing ultrafine powders with controlled particle size distribution (PSD) and morphology—key quality factors for battery materials. The technology leverages high-velocity compressed air or inert gases to induce particle collisions, facilitating particle size reduction without mechanical contact, minimizing contamination.

Key process features include:

• Vortex generation via tangential injected compressed gas creating a fluidized bed where particles continuously collide and fracture.

• Cyclonic separation efficiently removes fine particles from the gas stream.

• Adjustable классификация wheels allow precise PSD control vital for battery performance consistency.

3. Important Technical Considerations in Jet Pulverizers for Battery Powders

Энергоэффективность

Optimized nozzle and milling chamber designs reduce air consumption significantly—up to 50% savings compared to older models—cutting operational costs while maintaining grinding efficiency.

Particle Size and Purity

Battery materials demand narrow PSDs with high uniformity to improve electrode coating, charge cycles, and energy storage consistency. The use of full ceramic or stainless steel components minimizes metallic contamination, often kept below 10 ppb, crucial for high-purity applications.

Process Control and Automation

Advanced mills feature fully automatic control systems with intuitive interfaces enabling one-touch start/stop and real-time monitoring, enhancing reproducibility and yield. ongoaltech

Product Quality and Output

The integration of labyrinth and gas sealing prevents escape of oversized particles, boosting finished product qualification rates and reducing waste.

4. Market Growth and Industry Data

The battery materials market is projected to expand robustly, reflecting broad electrification trends:

| Metric | Value |

| Market size (2025, USD) | 64.5 billion |

| Projected market size (2035, USD) | 116.6 billion |

| CAGR (2025–2035) | 6.1% |

| Lithium-ion battery market share (2025) | 53.0% |

Key drivers include:

• Electric Vehicles (EVs): Require ~80 kg of graphite and lithium compounds per battery, fueling cathode and anode powder demand.

• Energy Storage Systems: Grid-scale storage demands high-performance materials supporting fluctuating renewable generation.

• Portable Electronics: Continuously expanding markets drive demand for consistent, high-quality battery powders.

Major regions leading production and consumption include China, India, and Brazil, supported by strong investments in electrification infrastructure and government incentives.

5. Challenges and Opportunities

Sustainability and Environmental Impact

Natural graphite mining and chemical synthesis implicate environmental footprints. Jet Pulverizers’s clean, low-contamination process supports greener manufacturing pathways by reducing waste and energy consumption.

Innovation in Material Compositions

Research into silicon anodes and solid-state batteries increases the requirement for precision milling of diverse powders, pushing Jet Pulverizers technology to evolve with adaptable designs for fragile or reactive materials.

Supply Chain Developments

Collaborations, such as India’s Khanij Bidesh India Ltd. joint venture, aim to localize battery material supply chains, impacting procurement and equipment deployment globally.

6. Jet Pulverizers by EPIC Powder

Precision Control: Frequency-regulated классификатор wheels for tight particle size distributions tailored to specific battery chemistries.

Material Health: Non-contact milling chambers using ceramics or stainless steel ensure minimal contamination.

Energy Optimization: Jet nozzle configurations founded on extensive simulation lower air and energy usage.

Integrated Automation: Remote and real-time process control interfaces facilitate consistent high throughput and quality.

Эпический порошок

The evolving battery materials sector demands ultrafine powders with rigorous purity and size specifications. EPIC Порошковые Машины’s specialized jet pulverizers are engineered to support battery material producers in meeting the increasing demand, driving innovations and growth in an industry critical to global energy transition. Contact us today for a tailored solution.