NO. 369, Road S209, Huanxiu, Qingdao City, China

Roller Mill Application Materials

- Calcium Carbonate

- Dolomite

- Limestone

- Kaolin

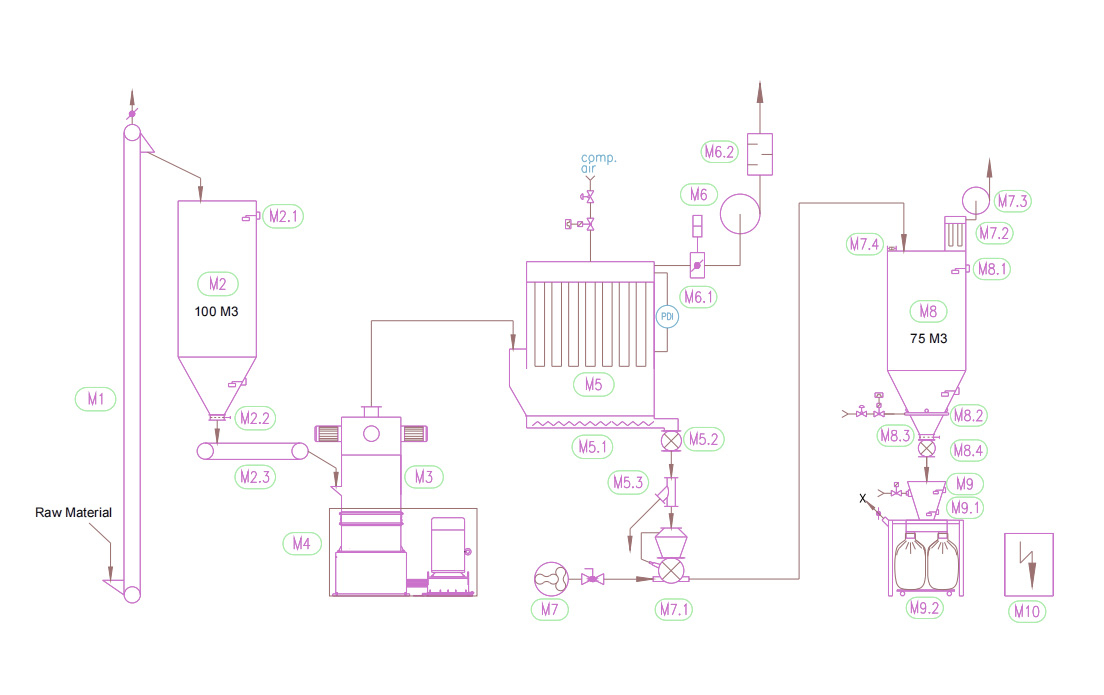

Milling Plant

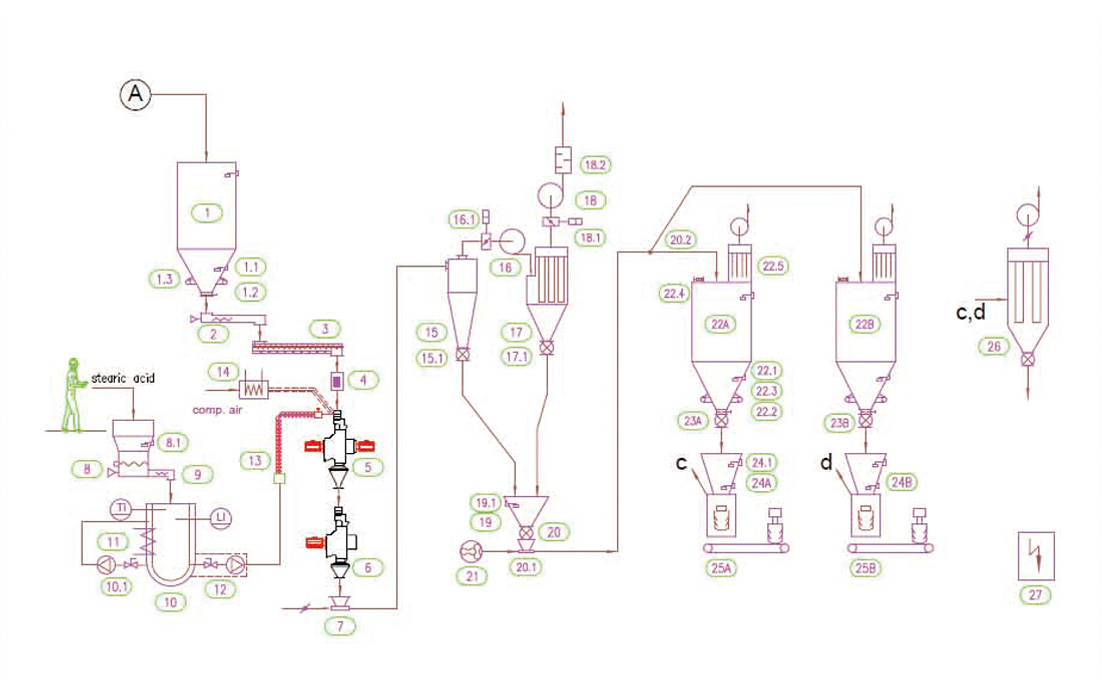

Coating Plant

Product Feature

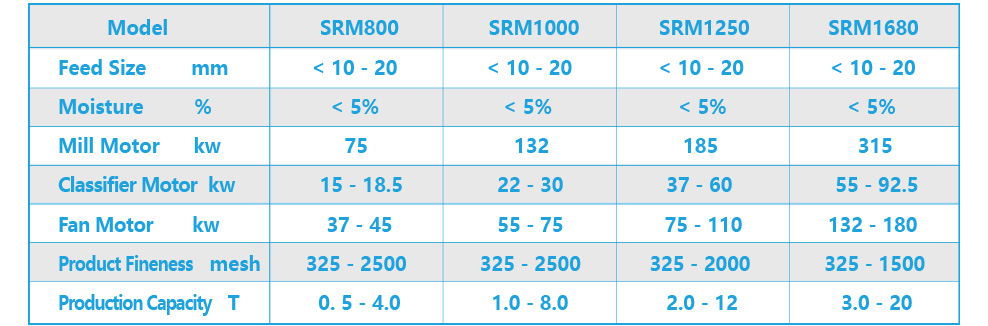

Particle SizeQuite different from Raymond mill which can produce particles coarser than 400 mesh only, roller mill can produce particles in the range from 325 mesh to 2500 mesh at one time. Its products range from coarse powder to ultra-fine powder, and the fineness of its end product can reach D97 ≤3μm.

Eco-friendlyThe plant runs under negative pressure, and the filter’s dust collection efficiency is as high as 99.9%, ensuring no dust pollution during running. In addition, the mill is equipped with a soundproof room and the fan is equipped with a silencer to reduce the noise and meet the national environmental protection standards.

ProductivityIn the case of producing a powder of the same fineness, roller mill is of higher productivity, lower energy consumption, and less production cost compared with ball mill, impact mill, jet mill, and agitator mill.

InvestmentIn the case of the same productivity, roller mill requires less capital investment with a shorter payback period in comparison with ball mill, impact mill, jet mill, and agitator mill.

InstallationThe installation is simple, with no need for a multi-layer steel structure platform or concrete platform, nor large-scale civil engineering. It can be put into production soon after installation.

MaintenanceGrinding rollers and grinding rings are made of high-hardness wear-resistant materials, which have a long service life and ensure consistent and reliable operation.

WORK PRINCIPLE

Roller mill processes materials by impacting, compressing, and grinding.

A roller mill has multi-layer grinding rollers and grinding rings. The raw material first falls into the gap between the rollers and the grinding ring on the first layer. There is a large clearance between the rollers installed on the support and the pin shaft. When the material passes through the gap between the rollers and the grinding rings, it will be processed to fine powder by impacting, compressing, and grinding of the rollers. The material will be ground a couple of times when passing through the gap between the rollers and the grinding rings from top to bottom. The ground material falls onto the distribution plate by gravity and is forced to the classifying zone at the top of the classifier by the airstream. The material is separated by the classifier wheel into two factions: fine and coarse. The qualified fine particles pass through the vane gaps of the classifying wheel to the filtering system where they are collected. The coarse particles are forced to the inner wall of the classifying ring, and fall down to the grinding zone for further grinding.

PRODUCT PARAMETER

Related Products

COMPANY PROFILE

Qingdao EPIC Powder Machinery Co., Ltd. is a company specializing in the research and development of ultra fine powder processing technology, powder surface modification machines and powder deep processing machines such as renewable resources processing; provide a series of services such as related consulting, testing, project design, machines production and training.

Our technical team has more than 20 years of professional experience in the powder processing industry, and has accumulated rich experience in powder process design, equipment design, manufacturing, and complete project delivery. Our company now has 3 foreign consultants from Europe to provide us with professional technical support. With the strong support of experts and the unremitting efforts of the company's employees, we are confident to grow into an excellent supplier that can compete with top European powder equipment manufacturers .

The quality system

1. Strictly implement the ISO9000 quality management system standard;

2. Passed intellectual property management system certification.

Quality control

1. The raw materials are first-line brands at home and abroad, and the quality certification documents or the certificate of origin can be traced back.

2. Whole-process quality inspection of parts, purchased parts and outsourced parts;

3. Inspection specifications for the whole machine (13 categories, 67 small test items, 102 assembly quality control points);

4. High-quality customization of the whole machine assembly.

COOPERATIVE CUSTOMERS

SERVICE GUARANTEE

Reply within

30 minutes

8 hours to

give feedback

24 hours to

provide solutions

24 hours to

provide scheme design