NO. 369, Road S209, Huanxiu, Qingdao City, China

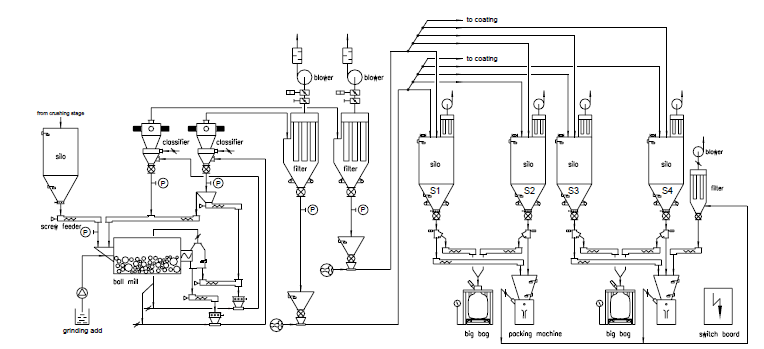

Classifying and ball mill production line,Ball Mill

Ball Mill

Product Description

Due to low speed rotation, ball mills are ideal for hard and abrasive materials like Quartz and Zircon sandas well as for grinding soft minerals as Calcium Carbonateand Kaolin. The mechanism of grinding takes place with minimum of impact and attrition energy, so ball mills are good for mass production of high-quality powder. Our ball mills vary from 110KW to 2000KW.

Product Feature

With Al2O3or silex or steel lining

Mainly designed with overflow type or grate discharge wall

With air through the mill or with air-swept principle to get cooler and take out grinded material

Outlet with hood overhead or gravity outlet

With slot wall with lifters and cone into outlet for steel lining mill

With counter screw to hold grinding media in the mill or grit for Al2O3/silex lining mill

The mills can be loaded with a high filling degree up to 30 - 40 % volume by grinding media

Supported on roller bearings with automatic lubricationsystem

Ball mills drives are optimal adapted to the grinding energy.

Equipped with servo drive motor for bigmills

Inlet chute for ball mill includes accessory for feeding grinding aid directly into the mill drum.

Other tailored design can be realized.

Principle

This process includes crushing (usually two-stage crushing, crushing, grading, packaging, transportation and hoisting). The ball mill can classify multiple classifiers in parallel, or connect the classification of multiple series products, and multiple grain sizes are produced. The ball mill and classifier form a closed-circuit circulation system.

Product Parameter

Our Commitment

We are committed to realizing service modernization and technology optimization, using technology to solve customer problems, and using service to improve customer experience.

-

Combination of production and research

-

Non-standard customization

-

One-stop service

-

Technical support and optimization

How long is your production period?

About two months. Our equipment is a non-standard customized product, and the production of each main component is put into production after signing the contract. Therefore, our production cycle is about 1-2 months.

What method is used for delivery?

After the production of the equipment is completed, we first package the equipment, put it into a container, and ship it by sea.

What if I bought your equipment, and it is not suitable?

The equipment produced by EPIC is a non-calibrated product. We select and design the plan according to the customer's needs, and design the plan based on the experimental data of the customer's material or experience and data. After meeting the customer's requirements, start manufacturing. Therefore, our products meet customers' production requirements, provide customers with comprehensive guidance and installation services, and strive to solve customers' production and installation problems.

What are your company's after-sales services?

EPIC is committed to building a professional service team for customers. After-sales service is our key area. We can provide you with a 1-year warranty and provide you with professional on-site installation technical guidance. Each set of products will be There is a set of fragile accessories as a gift, and at the same time, EPIC can provide you with a free equipment upgrade program for the products you purchase.