NO. 369, Road S209, Huanxiu, Qingdao City, China

Air Classifier, Airflow Classifier, Air Separator, Classifier

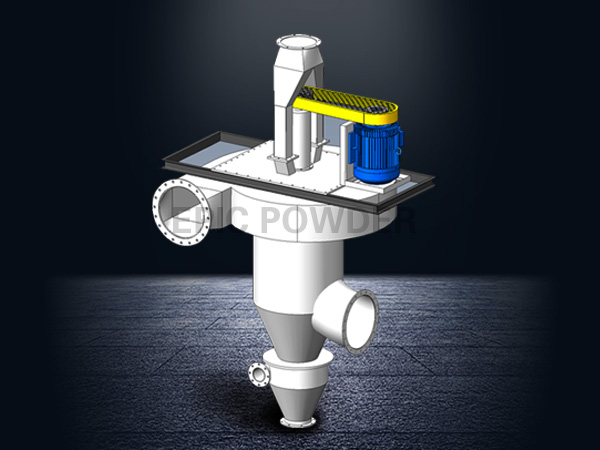

Air Classifier MBS

Product Description

MBS air classifier has both special wheel and deflector, which makes it good for the medium-fine separation range between approx. d97 20 - 200 micron. The high output, high efficiency and low energy consumption of fine powder are the general guidelines.

Product Feature

Pressure drop is low, energy consumption is low.

Good top cut for both very fine product and medium-fine product.

It can be designed for production of wide range of fineness, especially very coarse grade of powder product. Generally speaking, the design for fine separation can be used for max. fine upto 8micron, and the design for coarse separation can be used for max. coarse upto 200micron.

We offer not only small model for small capacity, but also big model for large scale production. Max. feed rate of the biggest model can be 800 t/h.

Wear resistant construction is available for even the most abrasive applications.

It can be integrated with ball mill in closed circuit, for size reduction of various materials.

Principle

The feed inlet of classifier is on the top of classifier. The feed material goes into the classifier from top by gravity, and falls to the centrifugal plate of classifying wheel. The feed material would be distributed uniformly and radially dispersed towards the baffle ring, and routed downwards into the classifying zone. The classifying air enters the spiral housing and flows through the helical deflector vanes and then the classifying wheel in centripetal direction. The fines would be taken by air flow into classifying wheel and fly into the cyclone collector or bag filter collector, meanwhile the coarse would be rejected by the centrifugal force of classifying wheel and fall down into the lower section of the classifier.

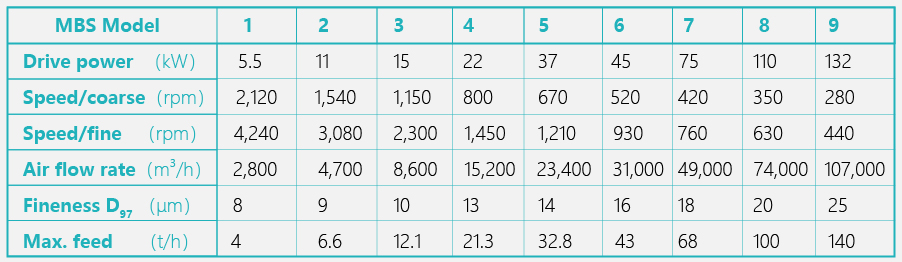

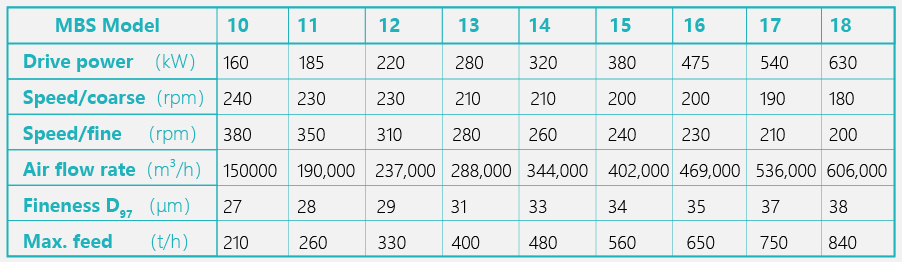

Product Parameter

Note: the throughput or production capacity depends heavily on raw material fineness, density, moisture and flow-ability. The data above is just for your reference.

Our Commitment

We are committed to realizing service modernization and technology optimization, using technology to solve customer problems, and using service to improve customer experience.

-

Combination of production and research

-

Non-standard customization

-

One-stop service

-

Technical support and optimization

How is the quality of your machines?

EPIC Powder Machinery has been engaged in the production of powder equipment for more than 20 years, focusing on technology research and development and product control. The high requirements for product quality are also the absolute requirements for our customers to be serious and responsible. We are deeply aware that product quality is the foundation of a company's long-term development. Because of this, our requirements for quality control must be comprehensive, multi-level, and high standards.

How about your price?

EPIC Powder Machinery's products are very cost-effective in the same industry. From product quality, performance, price to our after-sales service, we tailor-made for customers in accordance with the industry's high standards. EPIC is committed to achieving the integration of production and research, while repaying the trust of customers with high-quality services.

What if I bought your machiens and it is not suitable?

EPIC Powder Machinery producing machines are non-standard customized products. We select and design the plan according to the customer's needs, and make proposals based on the experimental data of the customer's material or past experience and data. After meeting the customer's requirements, start manufacturing. Therefore, our products meet the production requirements of customers, and we provide customers with comprehensive guidance and installation services, and strive to solve customers' production and installation problems.

How long is your production period?

About two months. Our machines are a non-standard customized product, and the production of each main component is put into production after signing the contract. Therefore, our production cycle is about 1-2 months.