NO. 369, Road S209, Huanxiu, Qingdao City, China

Jet Mill

【Technical Information】Causes of High-speed Airflow in Jet Mill: Laval nozzle

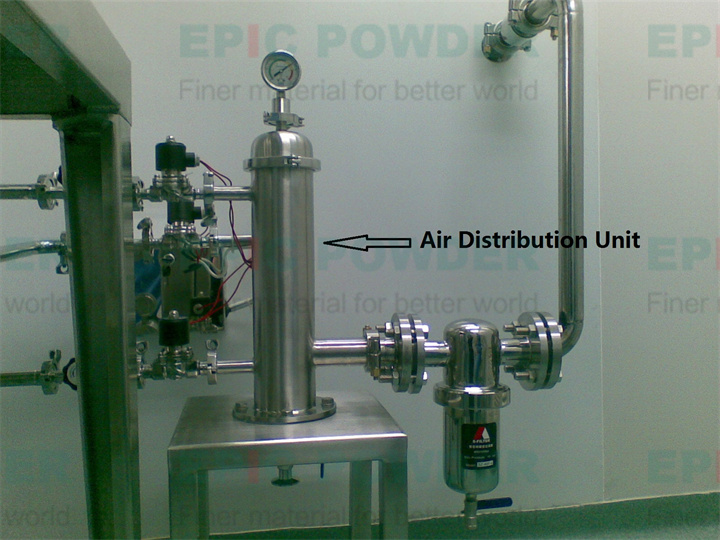

The compressed air used in the jet mill is sprayed into the crushing chamber at a high speed through the Laval nozzle after being filtered and dried. At the intersection of multiple high-pressure air streams, the materials are repeatedly collided, rubbed and sheared to crush.Why Does The Gas Flow Rate in Jet Mill Have Such Amazing Power

The crucial part of the pulverizer is Laval nozzle. The compressed air is accelerated into a subsonic or supersonic airflow through the Laval nozzle, and the ejected jet drives the material to move at a high speed, thereby pulverizing the material.

What Is Laval Nozzle

Laval nozzle is a middle contraction, asymmetric hourglass shaped tube, also known as "convergent-divergent nozzle". Laval nozzle is an important part of the thrust chamber, which can act as a "velocity increaser" in application.

How the Laval Nozzle was Invented

In 1888, the Swede Laval designed a pointed nozzle. He added a horn shaped opening at one end behind the pointed nozzle, so the gas was ejected at an unprecedented rate. As the front section of the pipe becomes thinner and thinner, the gas can continuously accelerate to the speed of sound. However, once the gas velocity reaches the speed of sound, it will reach a critical point. At this time, no matter how thin the pipeline is, the gas will no longer accelerate.

Therefore, in order to make the gas reaching the speed of sound continue to accelerate, Laval abandoned the practice of making the pipe narrower and chose to add a horn shaped opening at the front end of the pipe to widen the pipe, so that the pressure applied to the gas can be released instantly, and the cross-sectional area of the gas becomes larger, so as to continue to accelerate to exceed the speed of sound.

Laval nozzle endows the jet mill with great power. Therefore, the jet mill has many excellent properties, such as high kinetic energy, high efficiency, low pollution, fine particle size and so on.

The jet mill independently developed and produced by EPIC uses compressed air as power. When the compressed air is released through Laval nozzle, it will generate adiabatic expansion and absorb heat. The crushing process is generally not higher than 30 ℃, which belongs to low-temperature crushing and is suitable for crushing heat sensitive materials. It is widely used in pharmaceutical, chemical, mining, food, new materials and other industries.

In addition, EPIC upgraded the conventional jet mill, adopted unique high-temperature mechanical sealing technology and cooling technology, took high-temperature steam as the crushing medium, and drove the materials to crash and crush at high speed through the specially designed Laval nozzle, with the crushing particle size of 0.5~15µm which can be adjusted freely and stronger kinetic energy. It is usually used to treat fly ash, steel slag, chemical raw materials, etc. of power plants.

At present, the jet mill has been widely used in all walks of life. The equipment with high performance, high reliability, high mobility, good maintainability and economy is becoming the product pursued by users. According to the industry, the principle, method and technology of modular design will become an exploration way for the innovative research and development of jet mill.

Leave a Comment